Thermal modulation for gas chromatography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following description of the various embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

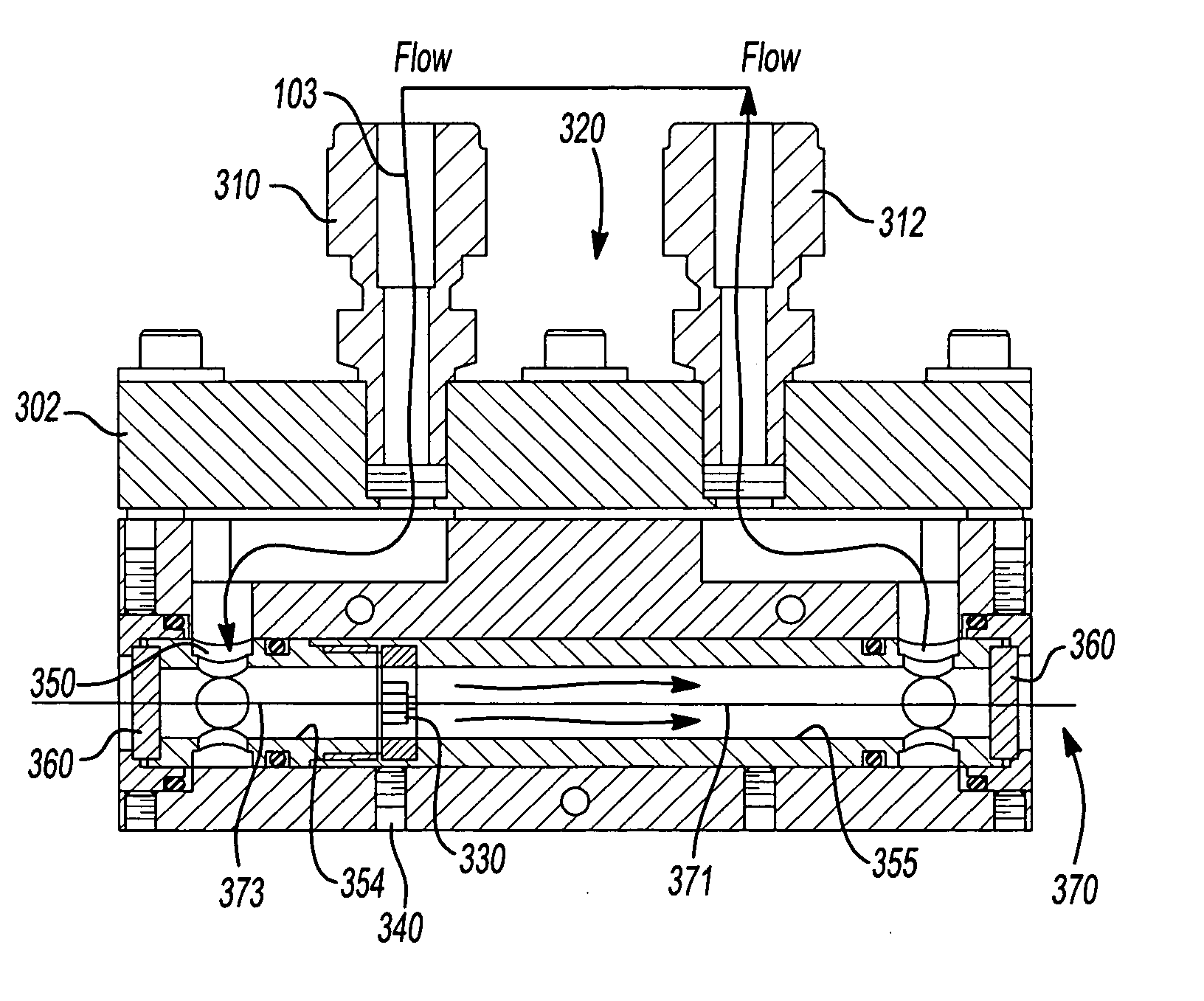

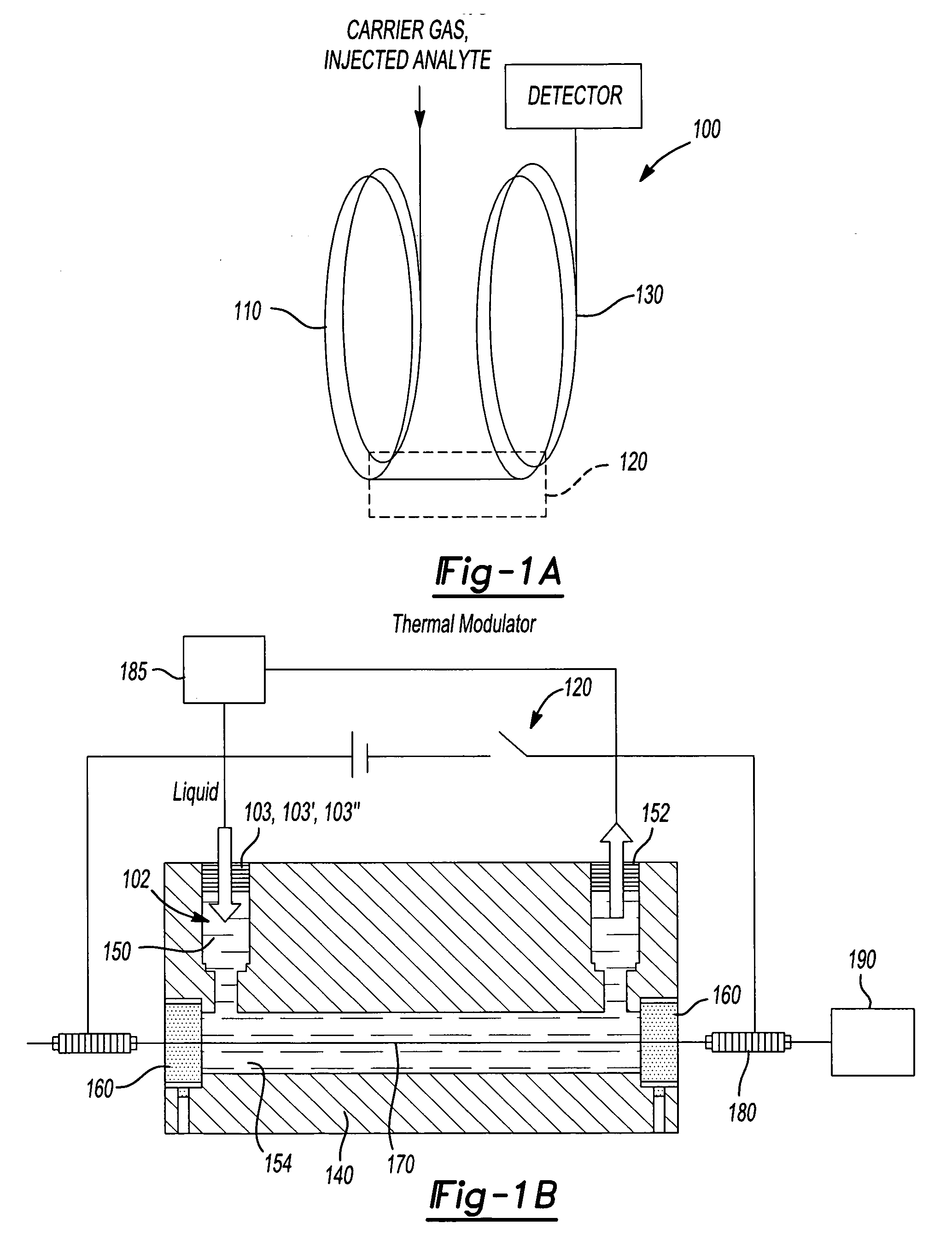

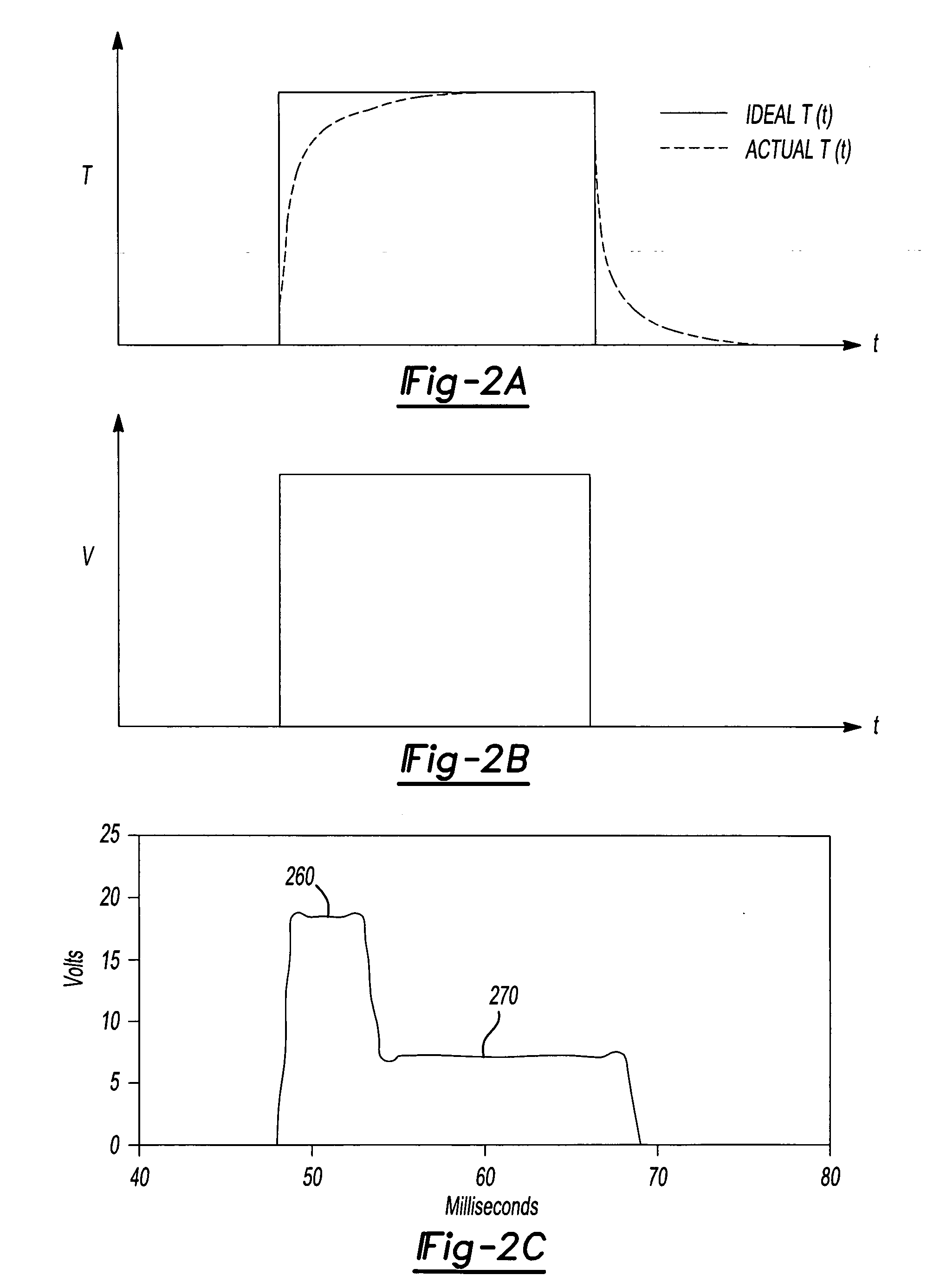

[0031] The present teachings provide devices and associated methods for achieving rapid and efficient thermal modulation of the capillary for two-dimensional gas chromatography (2DGC). The present teachings are also applicable to sample pre-concentration in both single column and 2D gas chromatography. In one aspect, the present teachings provide a thermal modulator device for gas chromatography. The thermal modulator device includes a cooling member and an electrically conductive capillary in direct thermal contact with the cooling member. In various aspects discussed below, the cooling member can be a gaseous, liquid or a solid coolant. A power supply 190 (shown in FIG. 1B) operates for controlling resistive heating of the capillary. The cooling member can also be a solid coolant that includes a layer capable of changing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap