Inkjet printer with interposing printhead capping mechanism

a printing head and interposing technology, applied in printing and other directions, can solve the problems of inability to service the above-mentioned system, nozzles are prone to blockage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

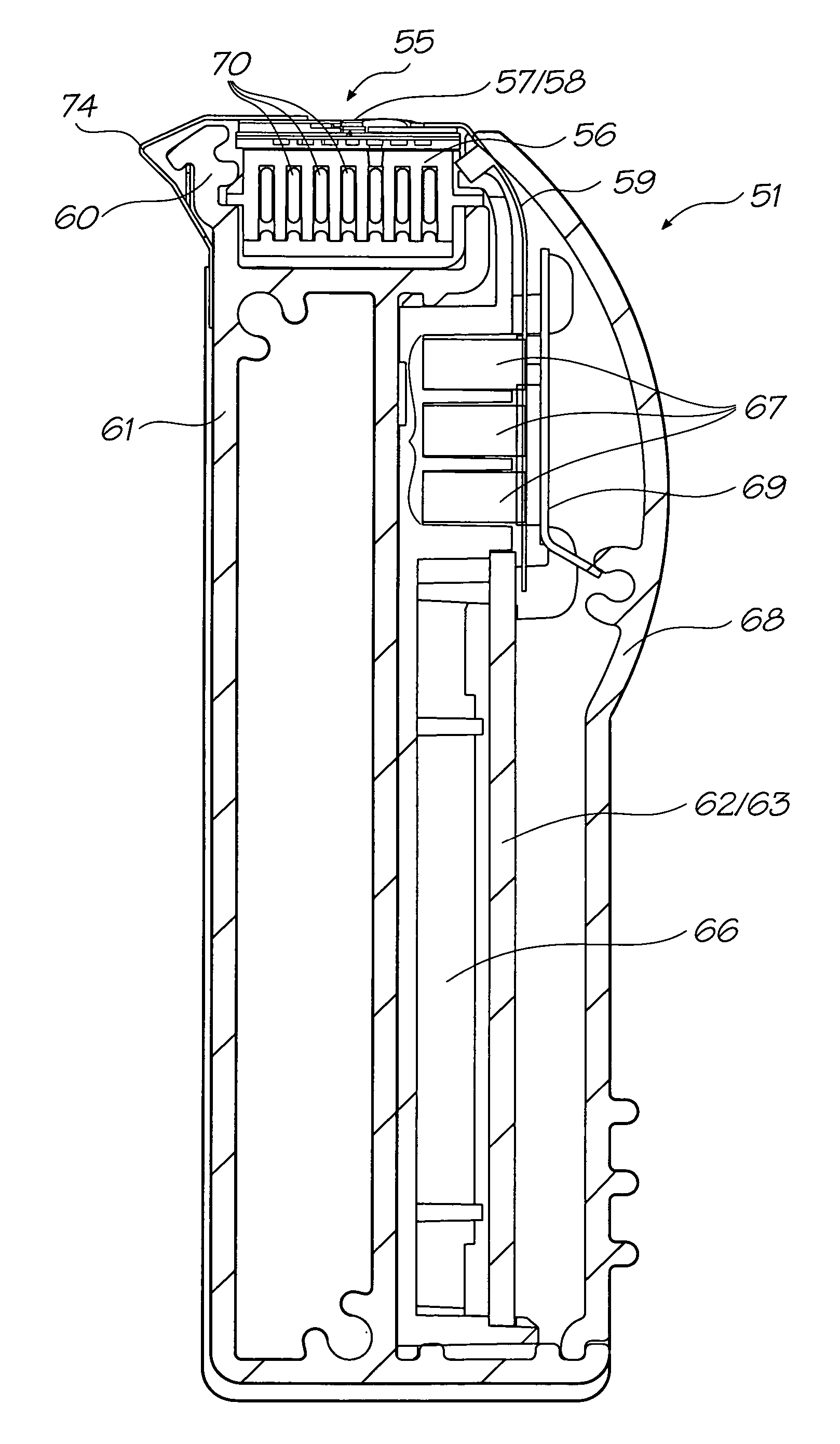

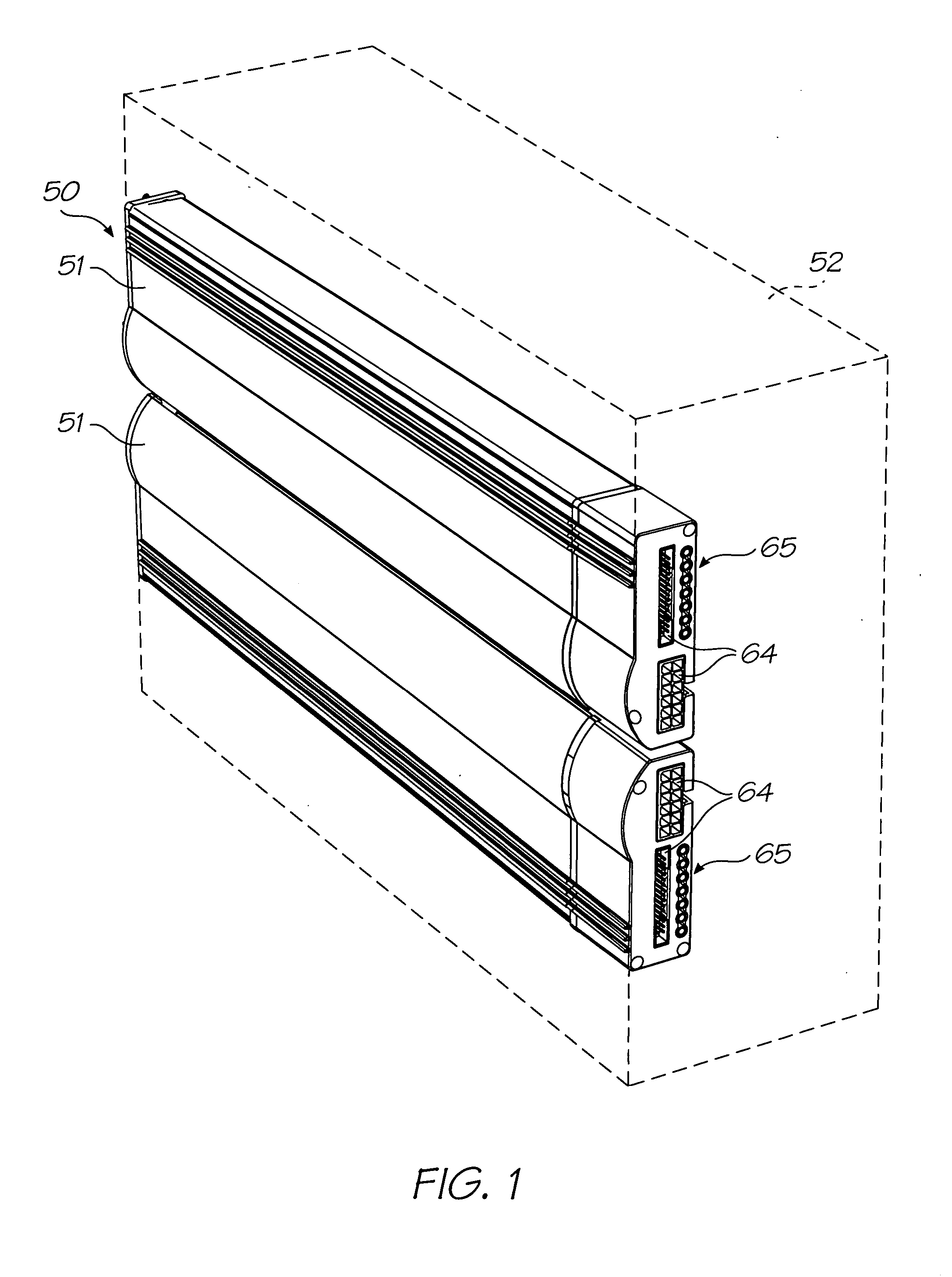

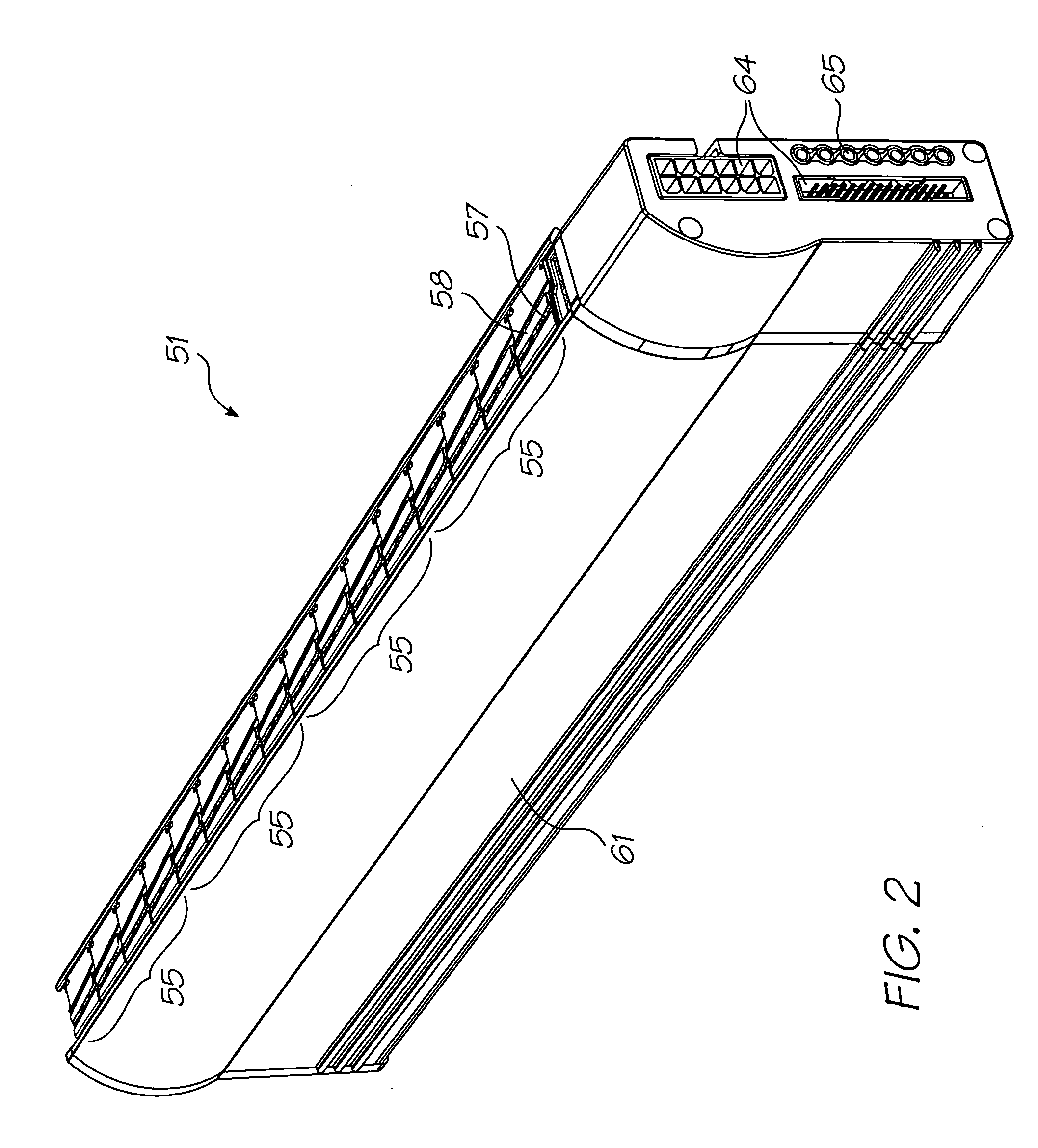

[1727] As illustrated in FIG. 1, a pagewidth printhead assembly 50 composed of two substantially identical pagewidth printheads 51 is mounted within a printer 52, although it will be understood from the following description that the printhead assembly might comprise a single printhead. The printer is shown in outline because it may be constituted by any one of a large number of printer types; including desk-top, office, commercial and wide format printers. Also, the printer may incorporate a single sheet feed system or a roll-feed system for print media (not shown), and it may be arranged for printing alpha-numeric, graphical or decorative images, the latter being relevant to the printing of textiles and wall coverings.

[1728] Each of the printheads 51 may, for example, be in the form of that which is described in the Applicant's co-pending US Patent Applications listed in the cross-references section above and all of which are incorporated herein by reference. But other types of page

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap