Ink jet printer for the labelling of goods with a write head and a supply tank

a technology of supply tank and write head, which is applied in the field ofink jet printers, can solve the problems of defective supply of compressed air, short supply of ink, and inability to detect defective ink pressure, and achieve the effects of reducing pressure in the ink line, erroneously displayed values, and air pressure energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

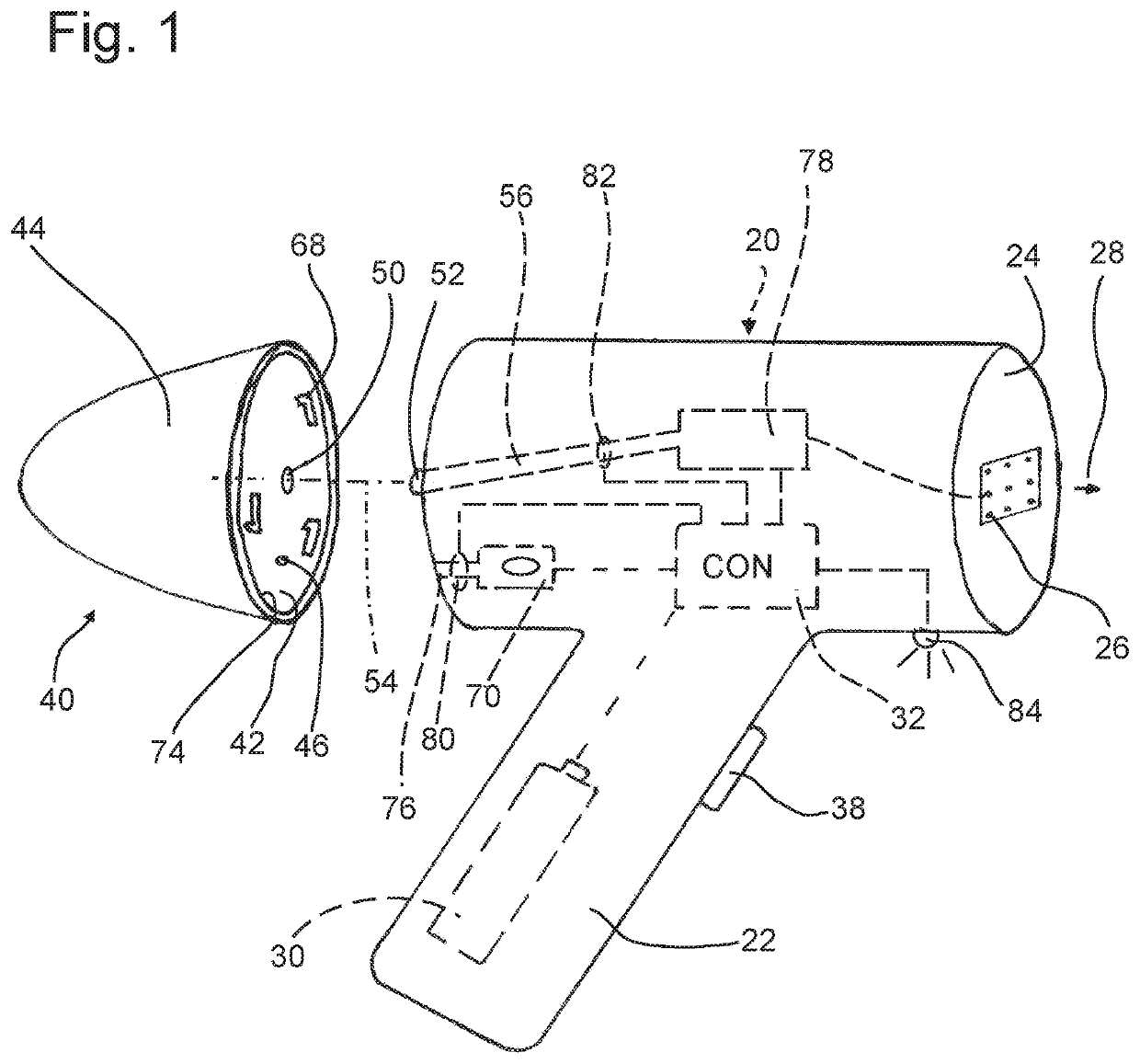

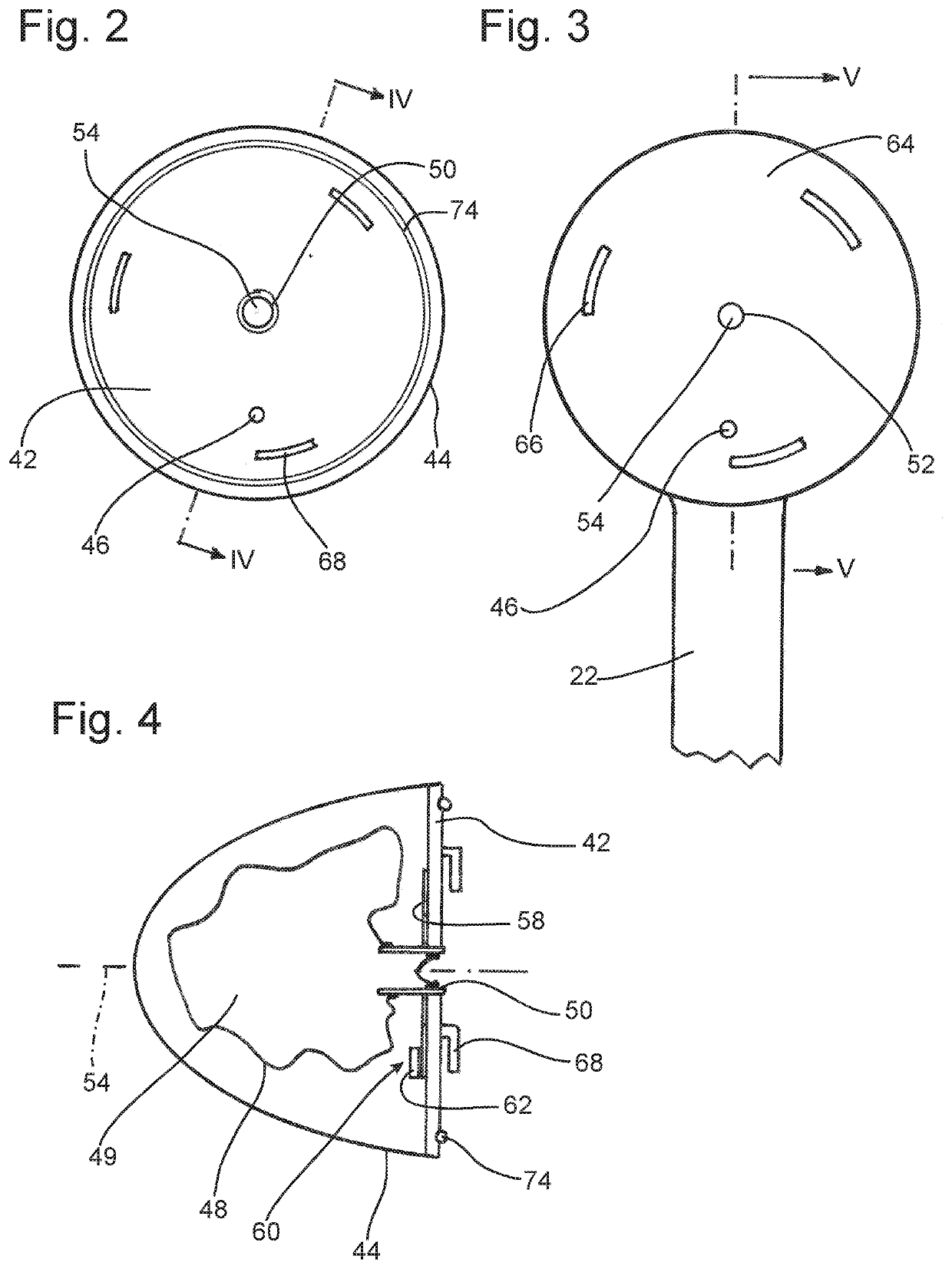

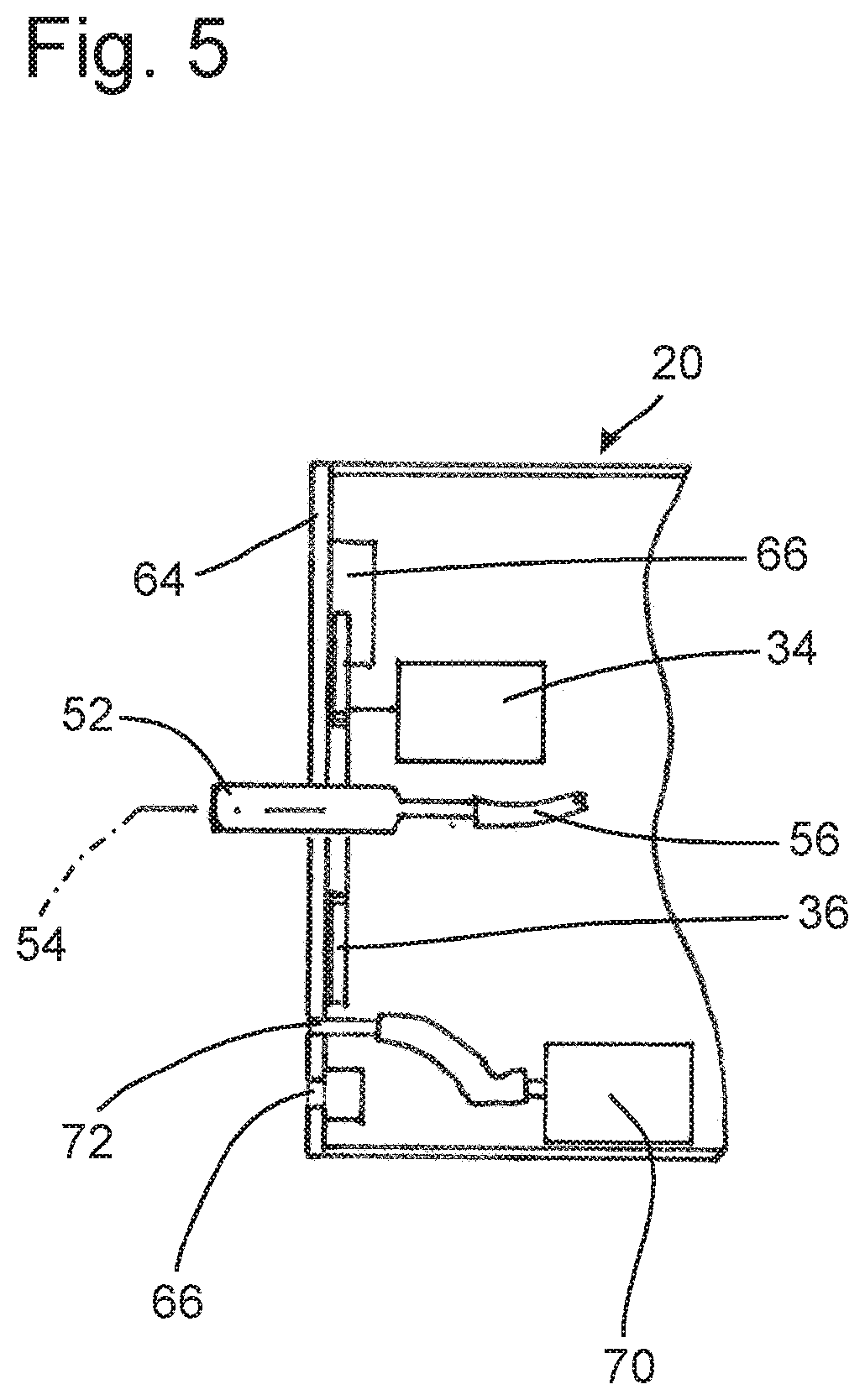

[0024]According to the two working examples, the ink jet printer for the labelling of goods is designed as a hand-held device. It comprises a main unit 20, which herein essentially is cylindrically formed having an attached handle 22. In FIG. 1, a frontal surface 24 is located at the right hand side of the main unit 20, where several ink 49 outlet openings 26 are provided. Discharge of ink is according to the arrow 28. Printing is preferably done with ink droplets. In the handle 22, a voltage supply 30 is accommodated, as represented as an accumulator. It is connected with a controller CON 32, which controls the overall operational procedure. In the handle 22, a release button 38 is mounted, through which a pressurizing procedure will be initiated.

[0025]In FIG. 1, on the left hand side adjacent to the main unit 20 a supply tank 40 is located, separated by a parting plane. It has its own housing. It is limited by a planar container wall 42, which has the shape of a disc, and by an air-t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap