Thermosensitive head

A technology of thermal head and heating element, applied in the field of thermal head, which can solve the problems of reduced printing quality and easy retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

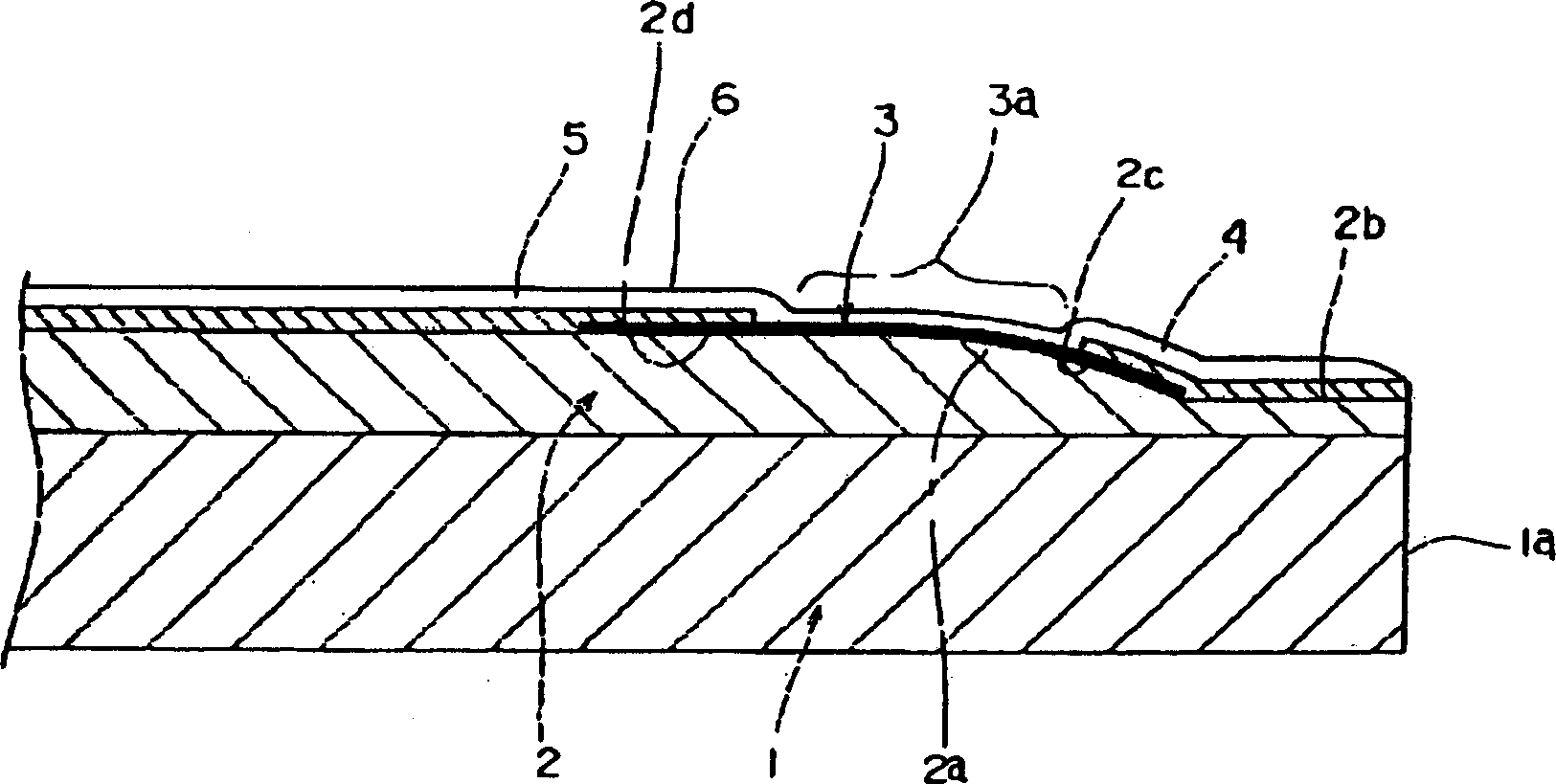

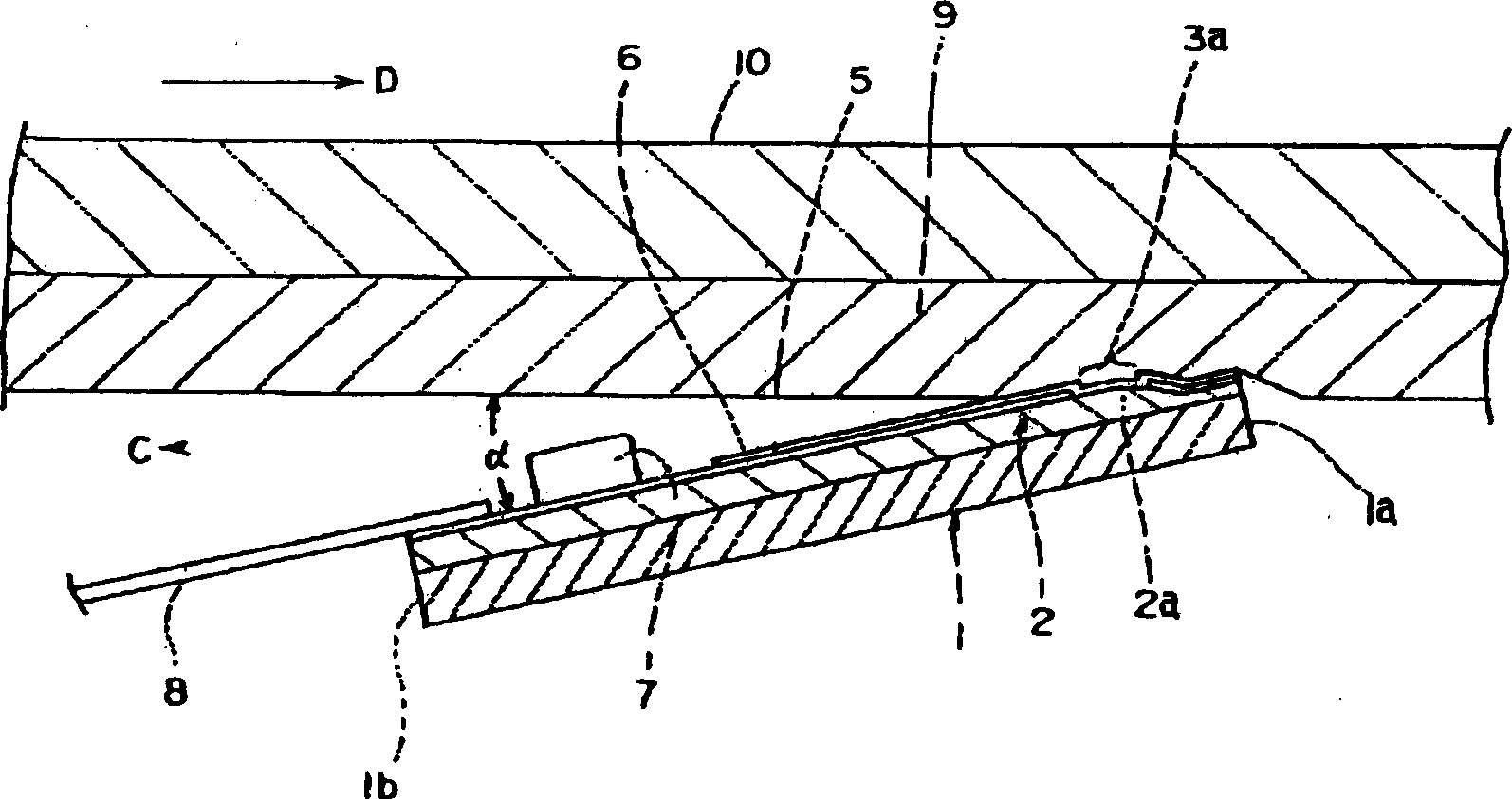

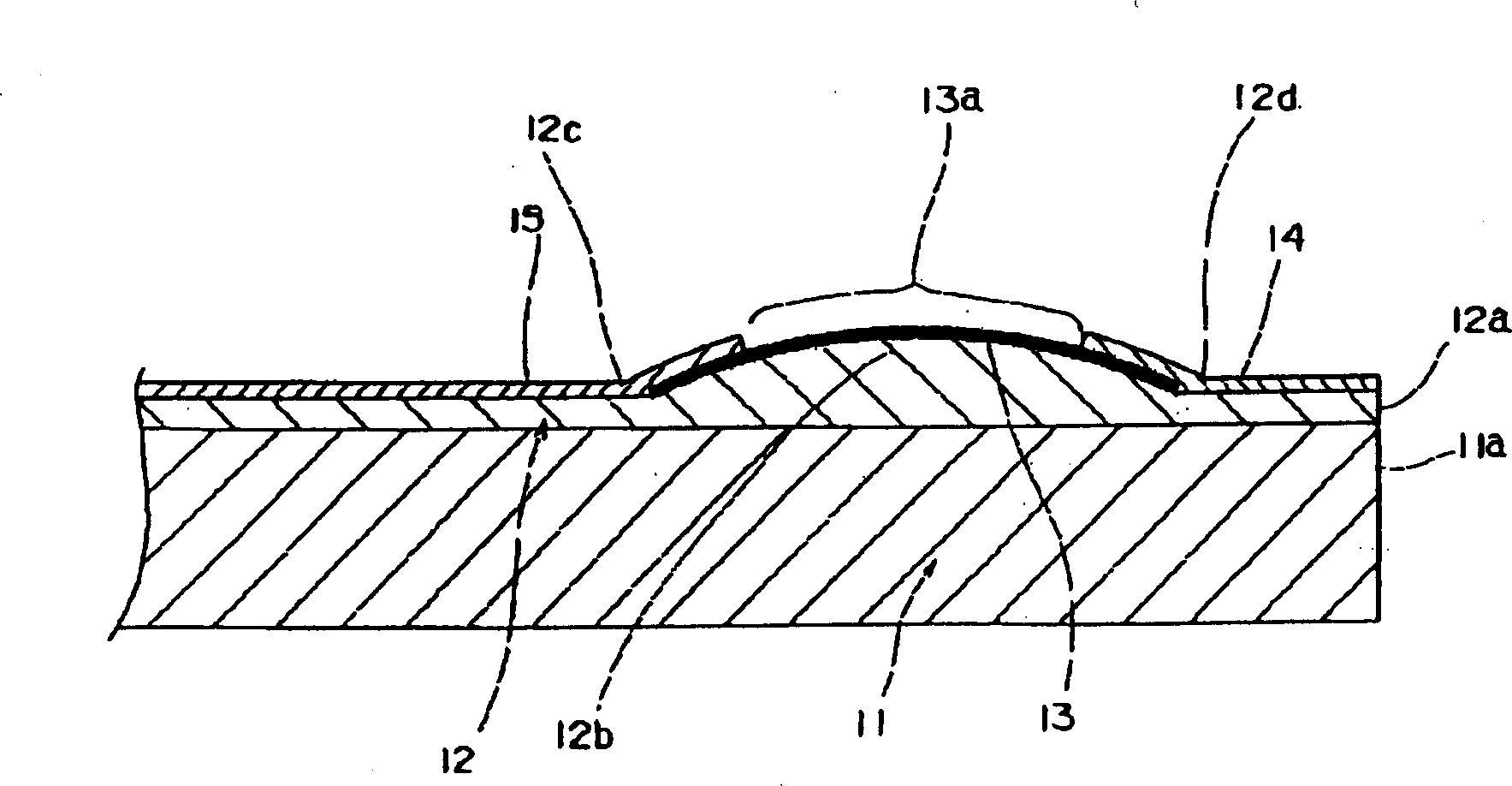

[0026] The thermal head of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a sectional view of main parts of the thermal head related to the present invention, figure 2 It is a schematic diagram illustrating the printing operation of the thermal head of the present invention.

[0027] First, the thermal head of the present invention, such as figure 1 As shown, a substrate 1 with good heat dissipation is arranged, and a thermal insulation layer 2 made of a glaze with good thermal insulation is formed on the substrate 1 .

[0028] The thermal insulation layer 2 is partially protruded on the surface by photolithography 2 technology to form a convex portion 2a. The convex portion 2a has a cross-sectional shape in a direction perpendicular to the direction in which the heat generating elements 3a are arranged to be described later, and is formed as an inclined surface 2c tow

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap