Non-wetting coating on a fluid ejector

A fluid ejector, wetting layer technology, applied in the direction of coating, metal material coating process, device for coating liquid on the surface, etc., can solve the problems of difficult to form patterns, expensive paint, not durable paint, etc. Droplet size, effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

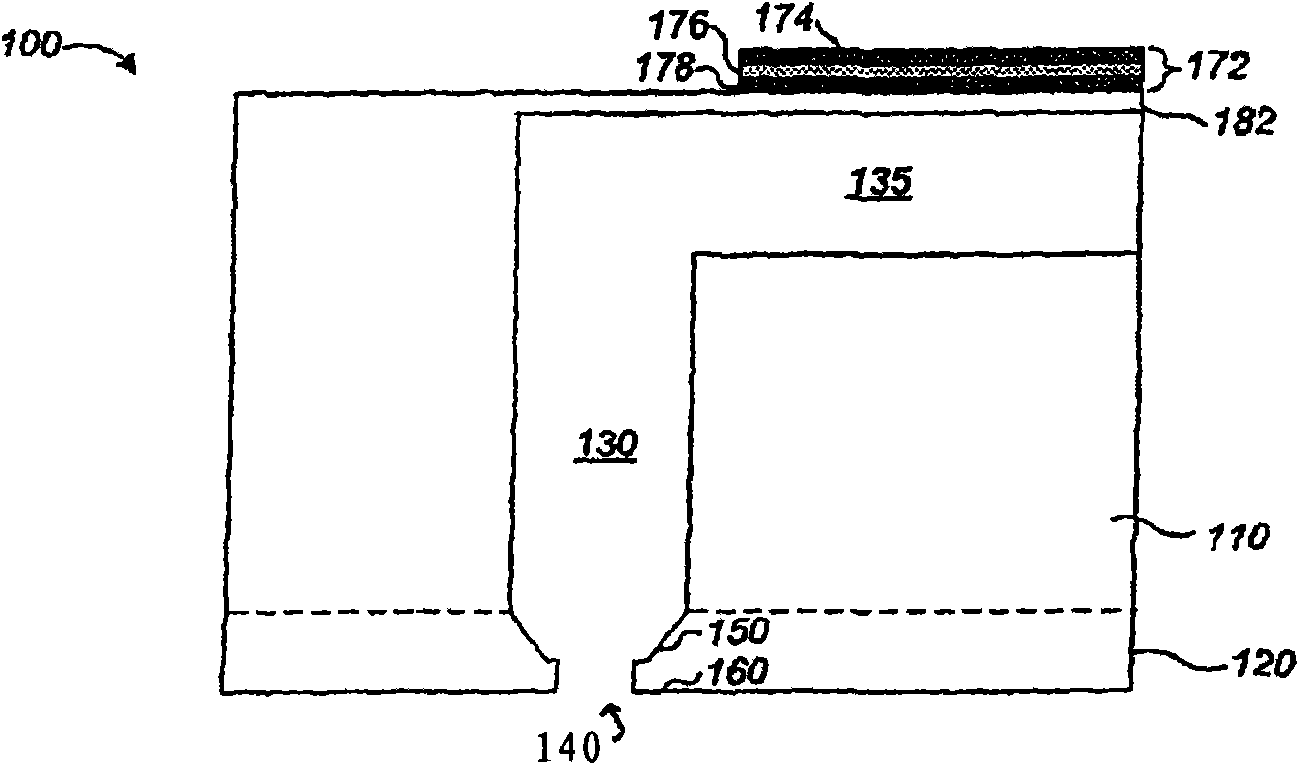

[0023] Figure 1A is a cross-sectional view of an uncoated fluid ejector 100 (e.g., an inkjet printhead nozzle) that can be configured as described in U.S. Patent Application Serial No. 11 / 256669 filed October 21, 2005. As stated above, the contents of US Patent Application Serial No. 11 / 256669 are incorporated herein by reference. Uncoated fluid ejector 100 includes flow channel module 110 and nozzle layer 120, both of which may be made of silicon (eg, single crystal silicon). In one embodiment, uncoated fluid ejector 100 is a single unit, and flow channel module 110 and nozzle layer 120 are not separate components. Diaphragm layer 182 is located above pumping chamber 135 . Actuator 172 pressurizes fluid (eg, ink, eg, water-based ink) in pumping chamber 135 . Fluid flows through down channels 130 and is ejected through holes 140 in nozzle layer 120 . The actuator 172 may include a piezoelectric layer 176, a lower electrode 178 (eg, a ground electrode), and an upper electr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap