Connector for connecting with flexible substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

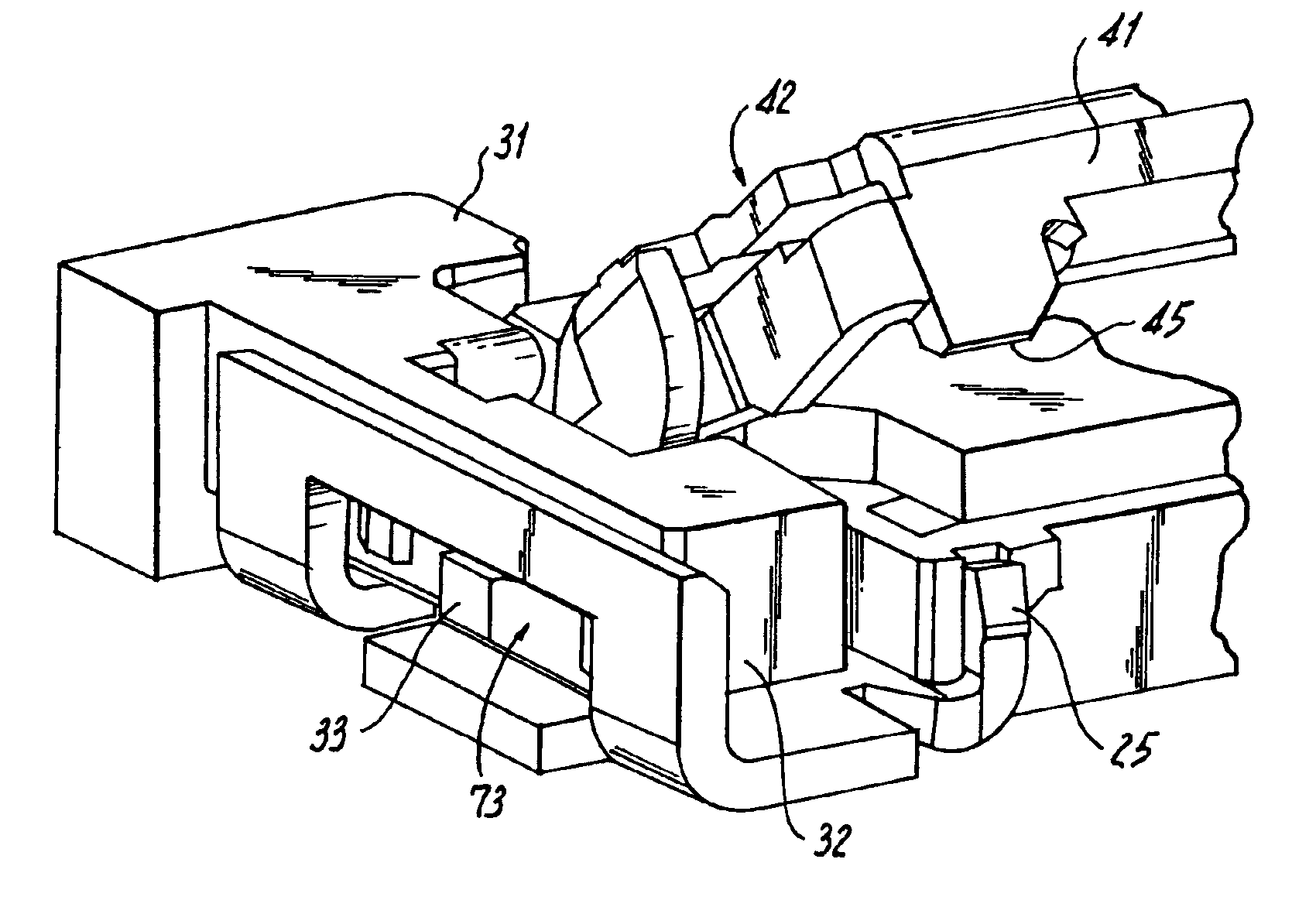

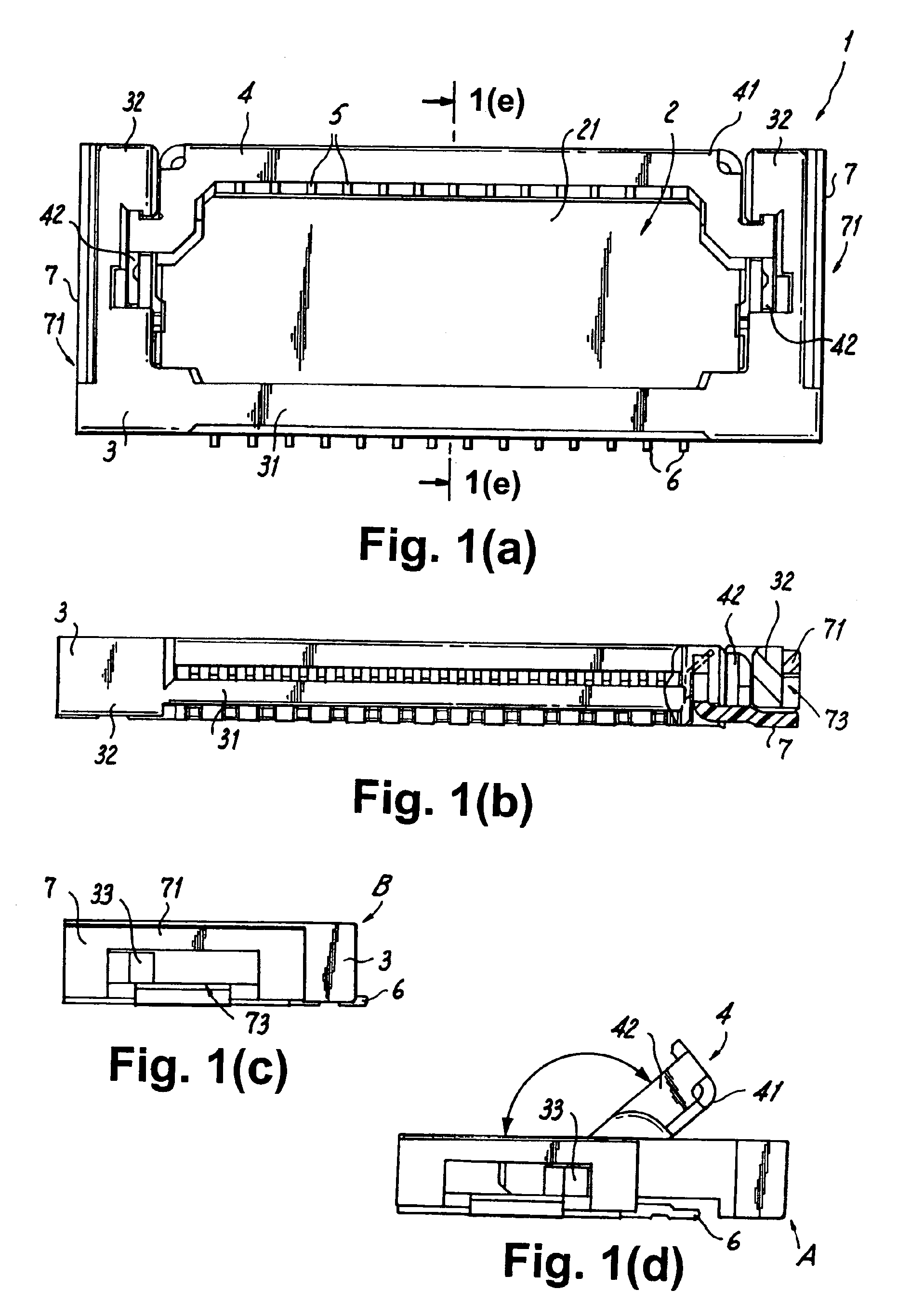

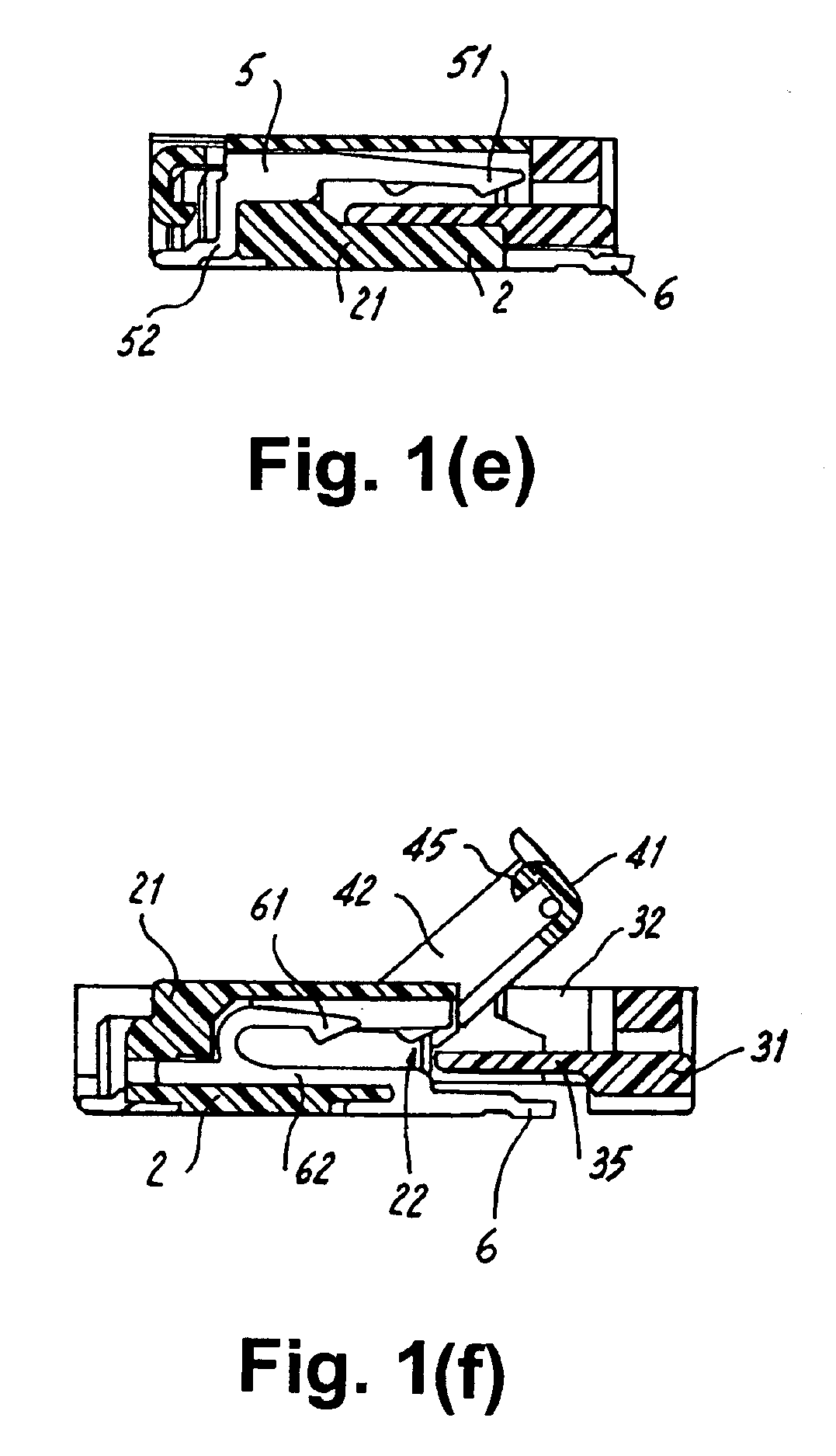

[0067]A flexible substrate connector 1 includes a housing 2, a slider 3, an operation lever 4, and multiple contacts 5, 6, as shown in FIGS. 1(a)-(f), and FIGS. 2(a) and (b). The contacts 5, 6 include contact points 51, 61, respectively. The connector 1 establishes an electrical connection between an element such as a printed circuit board and a flexible substrate 8 such as a FFC or FPC.

[0068]The flexible substrate 8 has a substantially flat shape, and multiple contact terminals are located on an edge of the flexible substrate 8. These contact terminals allow the flexible substrate 8 to connect electrically with contacts 5, 6.

[0069]The housing 2 includes a body 21, an insertion opening 22, and guides 7. The flat, rectangular body 21 is formed from a dielectric plastic resin. The insertion opening 22 is a recessed widthwise slit on the front surface of the body 21, and the flexible substrate 8 is inserted into the insertion opening 22 in the body 21 during operation. A guide 7 is locate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap