Spinning dust collecting device for spinner

A machine-woven dust collection device technology, applied in the direction of textiles, textiles, papermaking, weaving auxiliary equipment, etc., can solve the problems of large scale, non-uniform implementation standards, secondary pollution of dust collection, and poor dust collection effect. Achieve the effects of improving practicability and convenience of use, preventing dust from flying, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

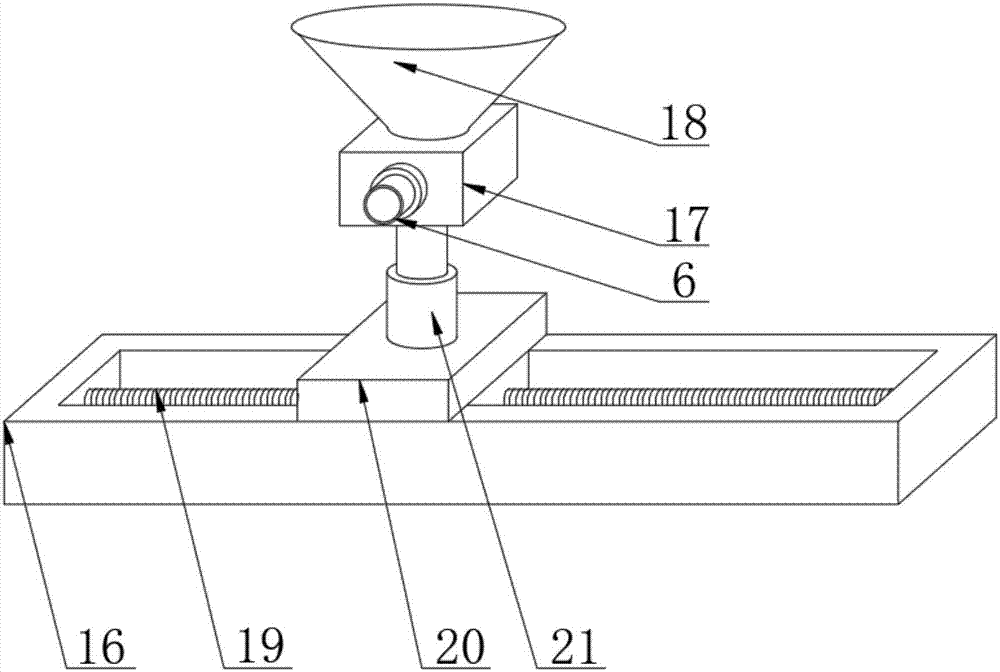

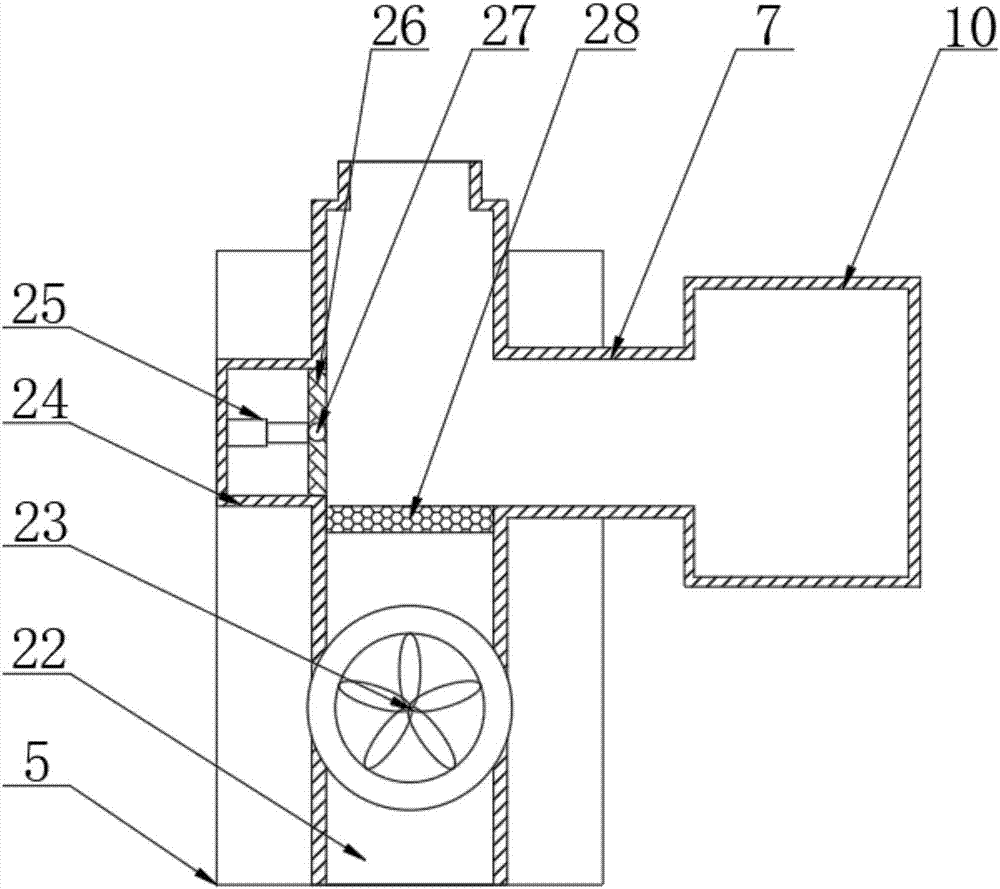

[0020] See Figure 1-5 , The present invention provides a technical solution: a textile dust collection device for textile machines, comprising a support frame 1, a fixing bolt hole 2, a support leg 3, a fixing plate 4, a processing box 5, a connecting hose 6, a connecting pipe 7, and an inlet Water pipe 8, solenoid valve 9, dust box 10, box door 11, drain pipe 12, servo motor 13, control board 14, electric control box 15, slide rail 16, re

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap