Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Continuous type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

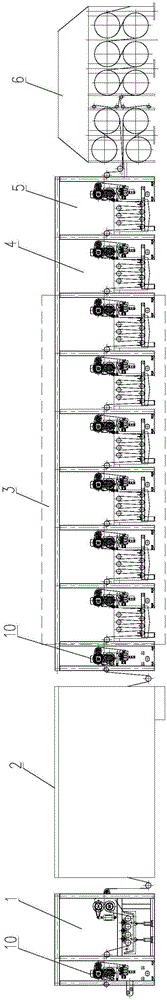

Continuous cold-rolling and steaming dyeing process and equipment of active dyestuff

PendingCN106638038AReduce consumptionReduce pollutionSucessive textile treatmentsTextile treatment machine arrangementsYarnAcid washing

Owner:杨立新

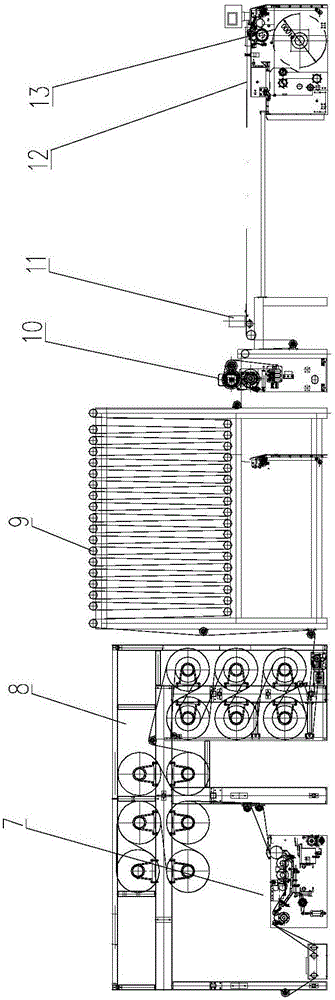

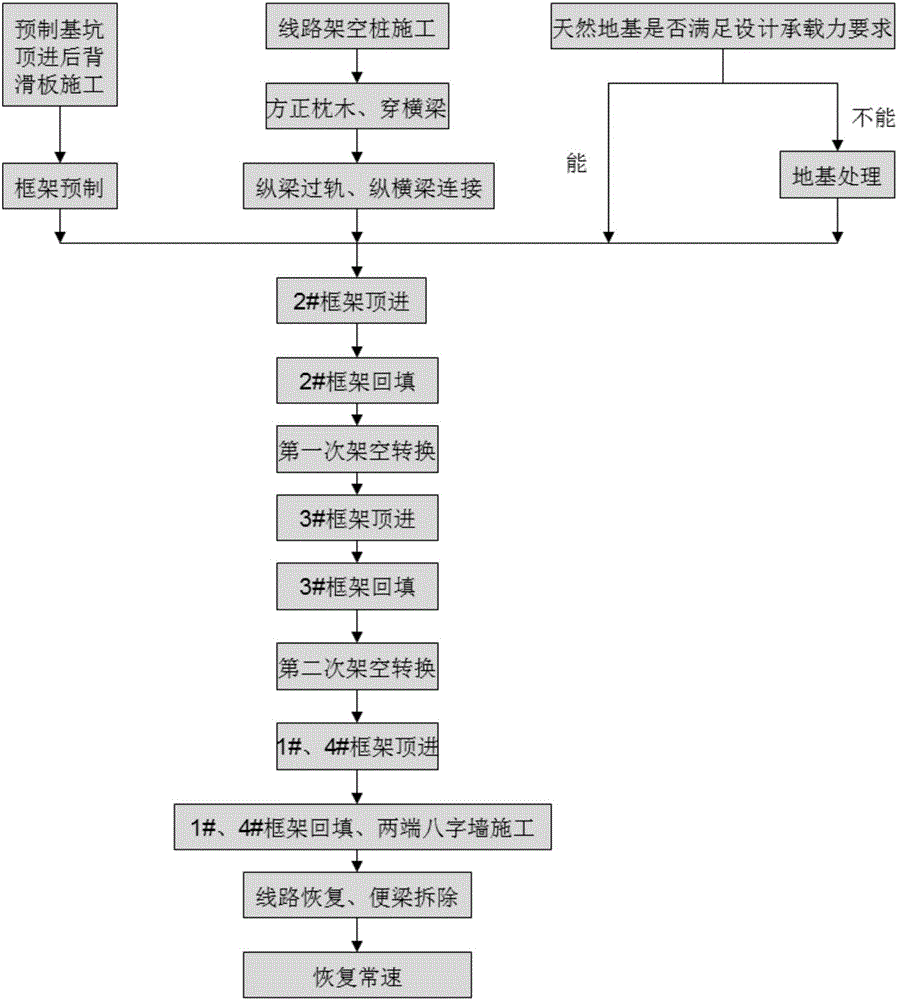

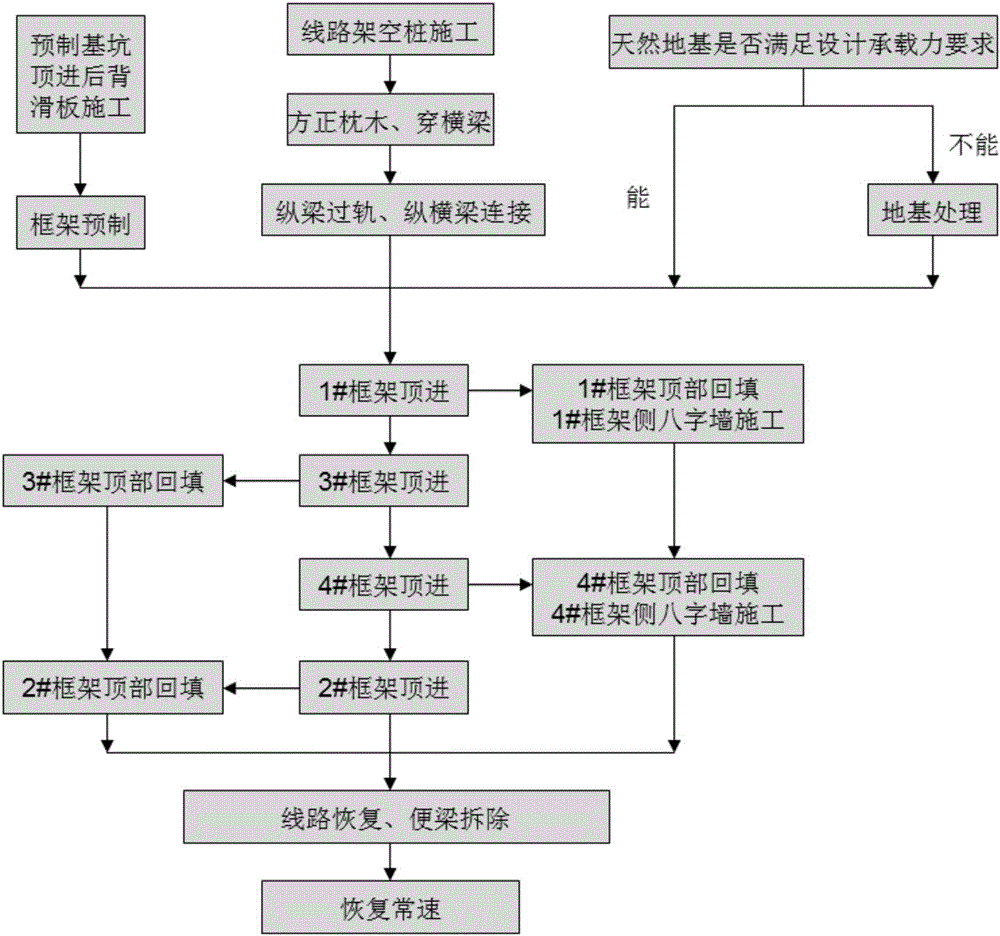

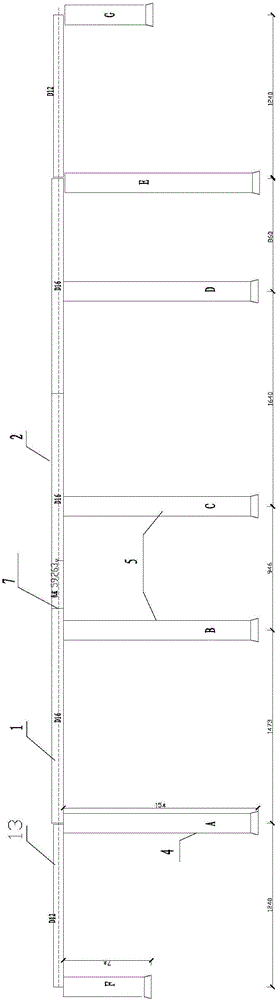

Construction method for continuous type construction auxiliary girder in jacking of railway box culvert and device for implementing construction method

Owner:长沙楚泰建筑劳务有限公司

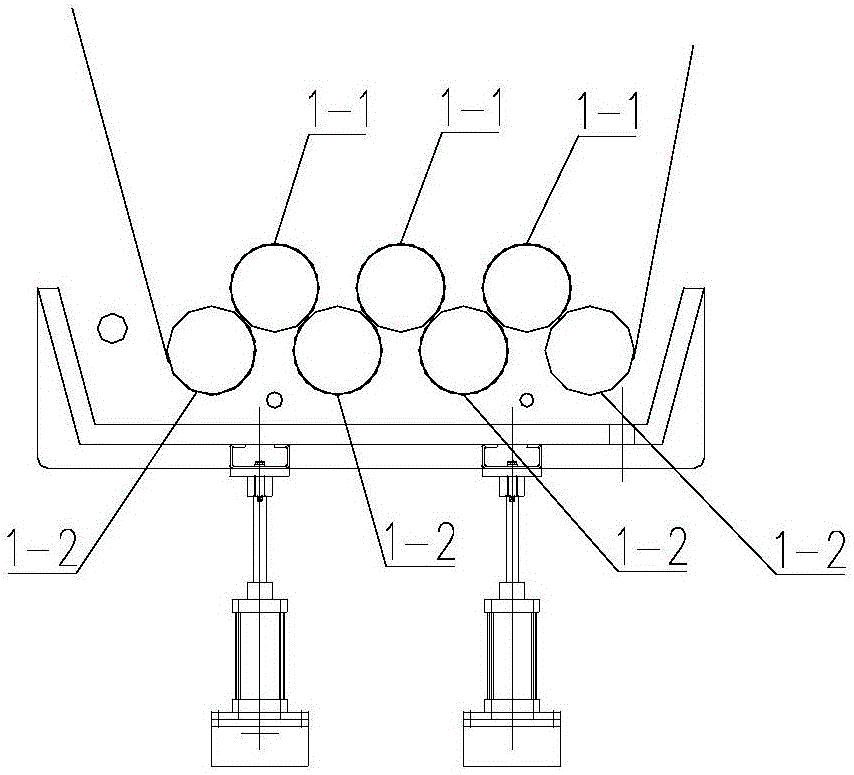

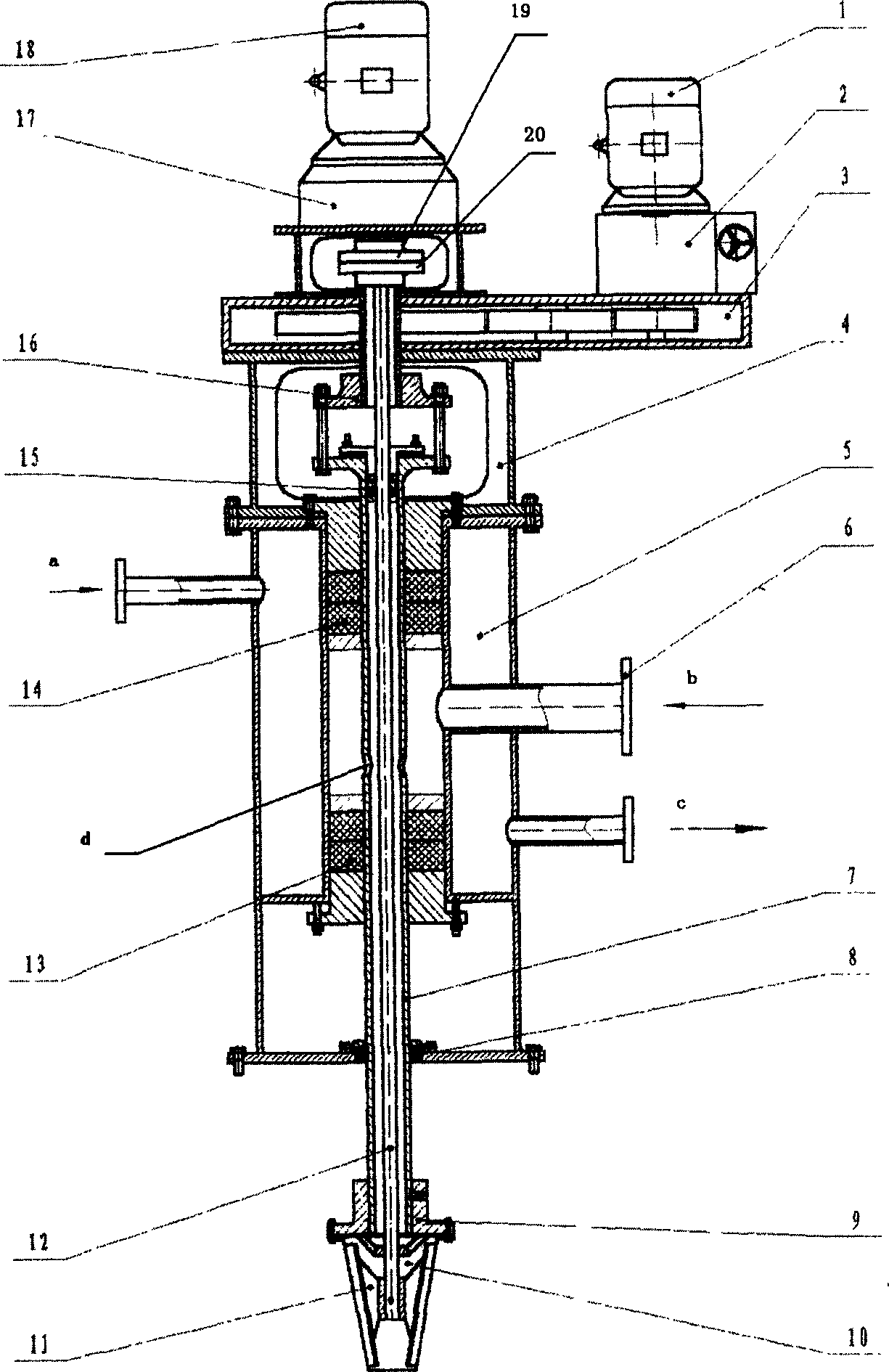

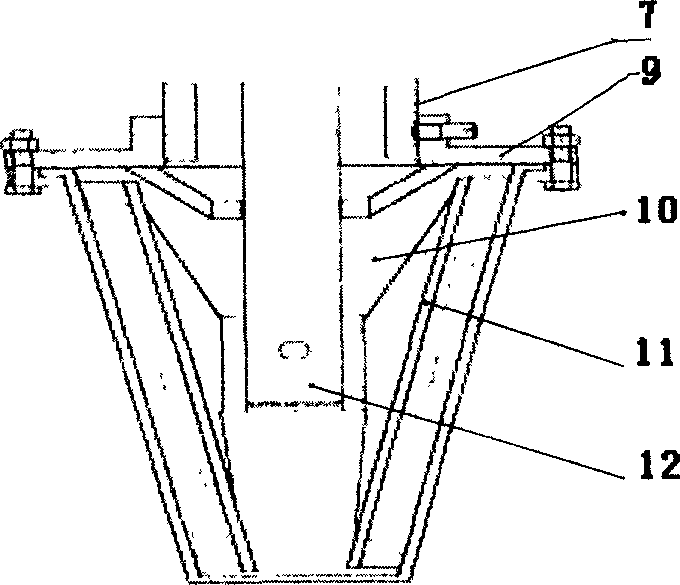

Intelligent continuous type oil press

PendingCN110328884AAutomatic and precise thickness adjustmentLow solidsFatty-oils/fats productionPressesUltrasonic sensorContinuous type

The invention discloses an intelligent continuous type oil press comprising a feeding mechanism, a pressing cage, a screw shaft, a cake correcting mechanism, an oil-refuse separating mechanism, a PLCcontrol cabinet and a machine frame. The material outlet end of the feeding mechanism communicates with a feeding opening of the pressing cage. The screw shaft is composed of a plurality of pressing bolts. The screw shaft is matched with the pressing cage. One end of the screw shaft is connected with a drive device, and the other end of the screw shaft is connected with the cake correcting mechanism. The oil-refuse separating mechanism is located below the pressing cage and provided with a vertical conveyer communicating with the feeding opening on the pressing cage. The pressing cage, the screw shaft and the oil-refuse separating mechanism are installed on the machine frame. The feeding mechanism, the transmission device, the cake correcting mechanism and the oil-refuse separating mechanism are all connected with the PLC control cabinet. The intelligent continuous type oil press has the beneficial effects that the functions of automatic feeding, automatic spiral pressing, automatic cake adjusting and automatic back pressing are integrated; the feeding mechanism is composed of a material suction machine, an ultrasonic sensor and an atomizer, automatic feeding and material stoppingcan be achieved, and the humidity and temperature of oil materials can be adjusted.

Owner:OIL CROPS RES INST CHINESE ACAD OF AGRI SCI

Continuous type solid liquid mixing granulation system

InactiveCN1562454AMeet different production requirementsGranulation by liquid drop formationMolten stateLiquid state

Owner:TIANJINSHI CHANGLUPRECISEBIOCHE MISTRY

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap