Construction method for continuous type construction auxiliary girder in jacking of railway box culvert and device for implementing construction method

A construction method and continuous technology, applied in the direction of road bottom, buildings, etc., can solve the problems of large impact of railway operation, long operation cycle, complicated procedures, etc., and achieve the effect of low input construction cost, high construction efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawings and specific cases.

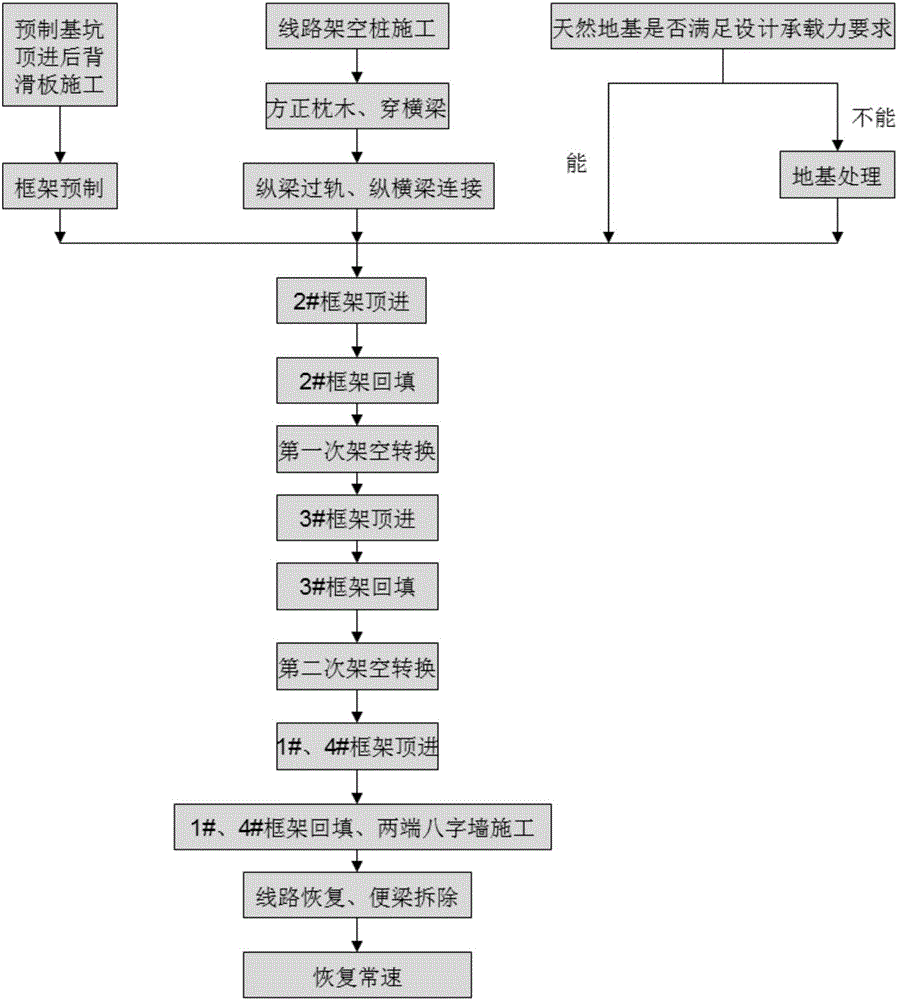

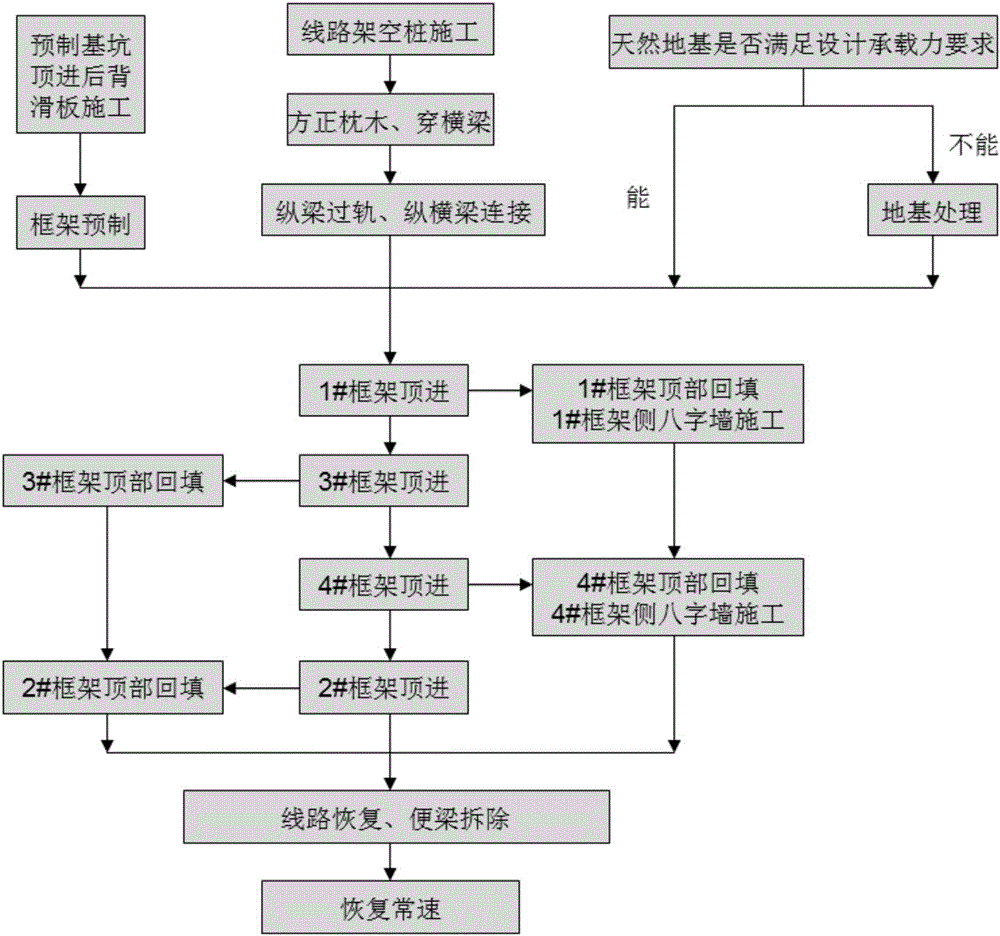

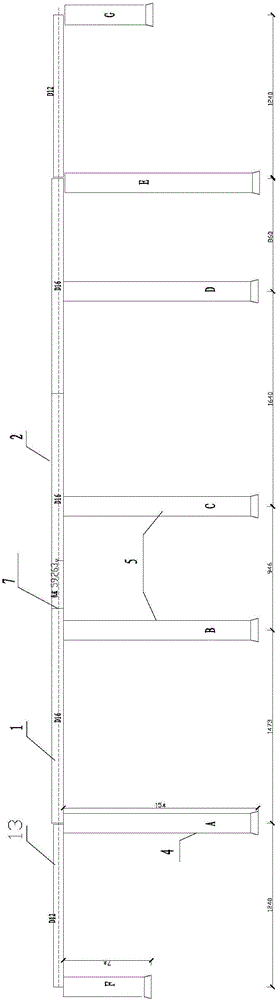

[0044] see figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 , the construction method of the railway box culvert jacking continuous type construction convenience beam provided by the invention, comprises the following steps:

[0045] Step 1. Build the continuous construction beam foundation and excavate the prefabricated pit; box culvert prefabrication: prefabricate the box culvert in the prefabricated pit, and the box culvert is a separate box culvert. In this case, there are 4 box culvert segments, numbered 1 in sequence No. 4 box culvert segment.....4 box culvert segment has a net span of 10+11.5+11.5+7 meters, and the span of the box culvert segment is within the allowable range of the maximum span of the continuous construction beam Inside;

[0046] Step 2,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap