Compressing head of trash compressing box

A technology of garbage compression and compression head, applied in the field of compression head, can solve the problems that affect the reliability of the device, the garbage is not easy to collect centrally, and the loading capacity of the box is affected, so as to achieve the effect of not easy partial load, reasonable distribution, and balanced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

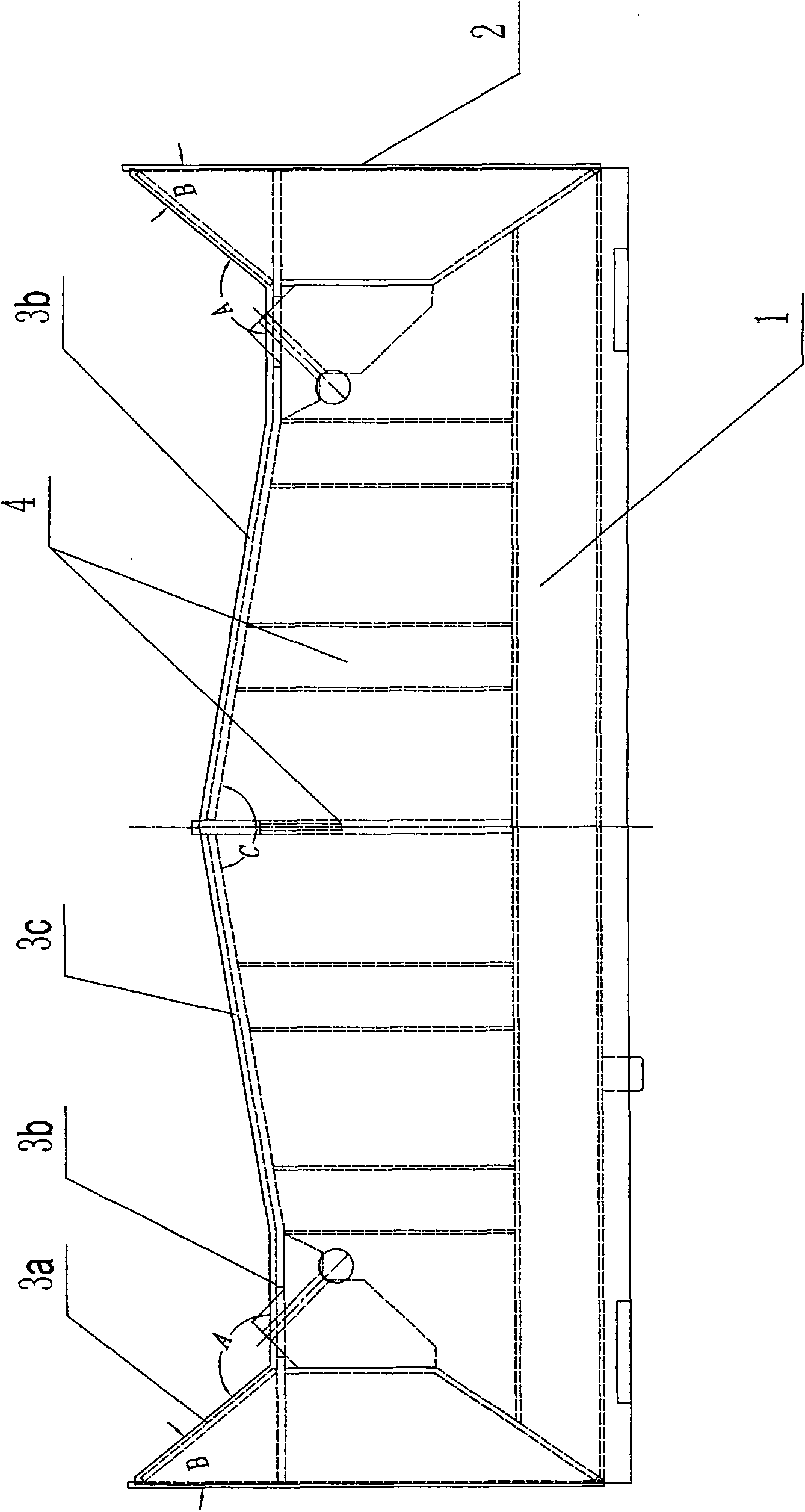

[0007] As shown in the figure, it is a compression head of a garbage compression box, including a compression head support mechanism 1 and a compression panel. Both the plate 2 and the support plate 4 are connected with the compression panel, the support plate 4 acts as a reinforcing structure, the compression panel is formed by connecting the side compression plate 3a, the transition compression plate 3b and the middle compression plate 3c, 3a, the transition compression plate 3b and the middle compression plate 3c are symmetrically provided with a pair of left and right, wherein the angle B between the side compression plate 3a and the side plate 2 is 35-45°, and the clamp between the two middle compression plates 3c The angle C is 155-165°, the angle A between the middle compression plate 3c and the side compression plate 3a is 125-135°, and the width of the side compression plate 3a is 1 / 10-1 / 5 of the width of the entire compression panel , to ensure that there is a long

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap