Intelligent climbing frame system for construction site

A construction site, intelligent technology, applied in the field of climbing frames, can solve the problems of lighting intensity setting in difficult lighting range, falling from high altitude, difficult supporting surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0065] Example 1

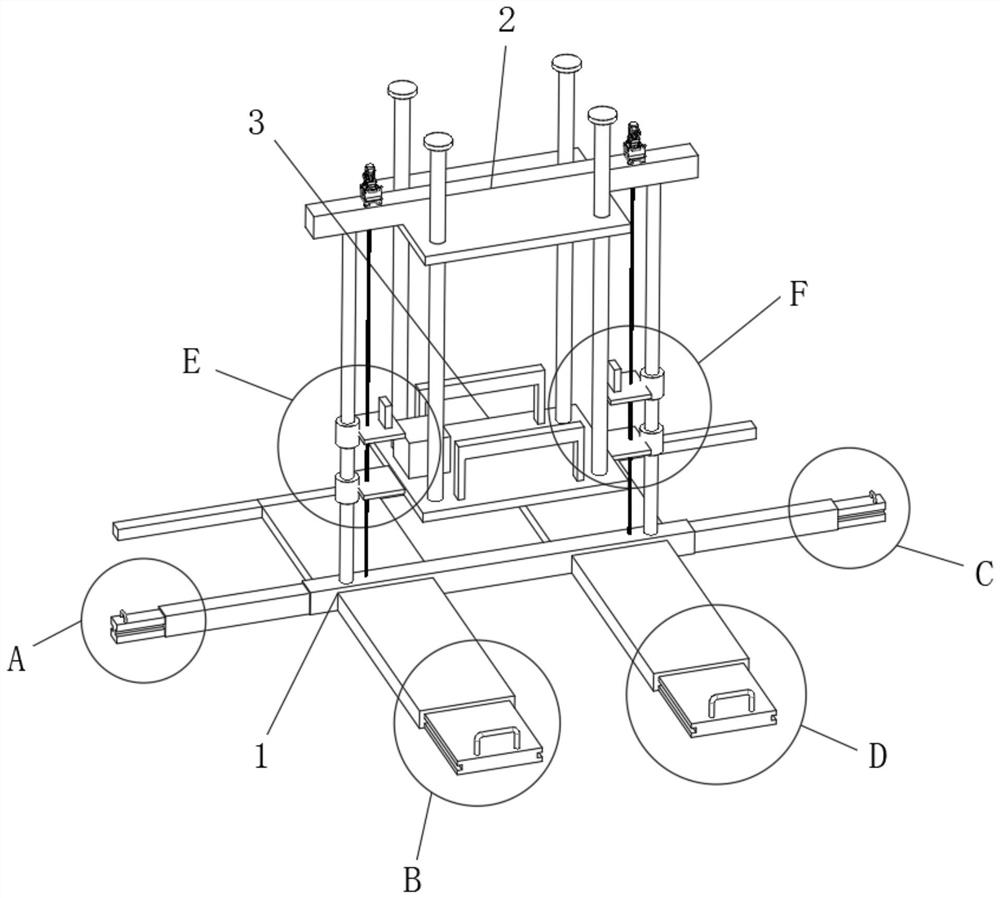

[0066] as Figure 1-19 As shown, according to an embodiment of the present invention, a construction site with intelligent climbing frame system, comprising:

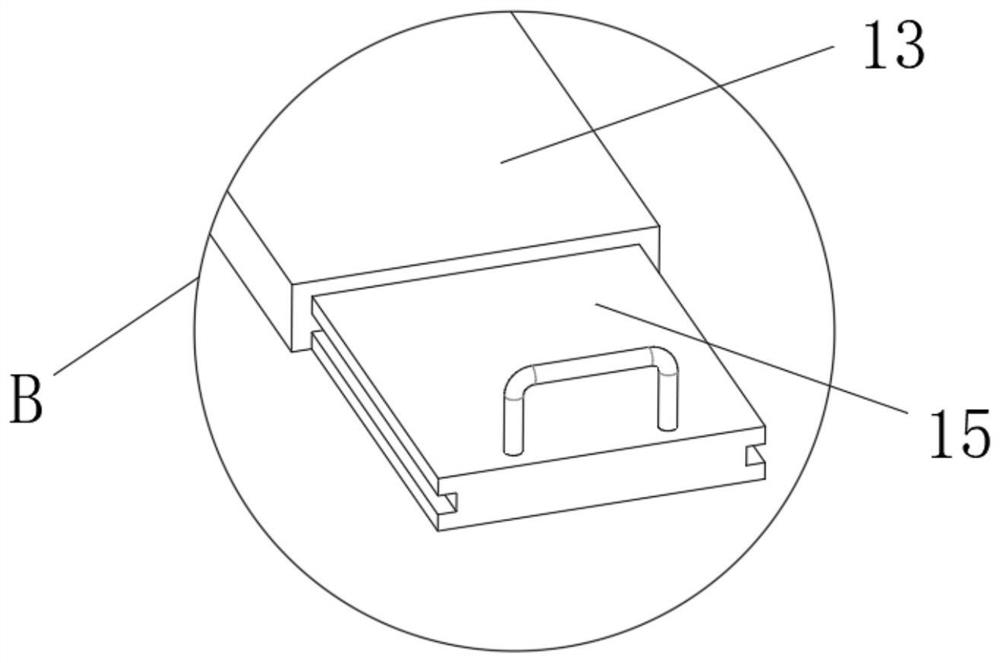

[0067] Support mechanism 1, support mechanism 1 includes a bottom beam 11, the bottom beam 11 on the front side of one end welded with a first support seat 12, the bottom beam 11 away from the first support seat 12 of the front side of the other end welded with a second support seat 13, the first support seat 12 is installed with a first sliding plate 14, and the first sliding plate 14 and the first support seat 12 sliding connection, the second support seat 13 is installed with a second sliding plate 15, and the second sliding plate 15 and the second support seat 13 sliding connection;

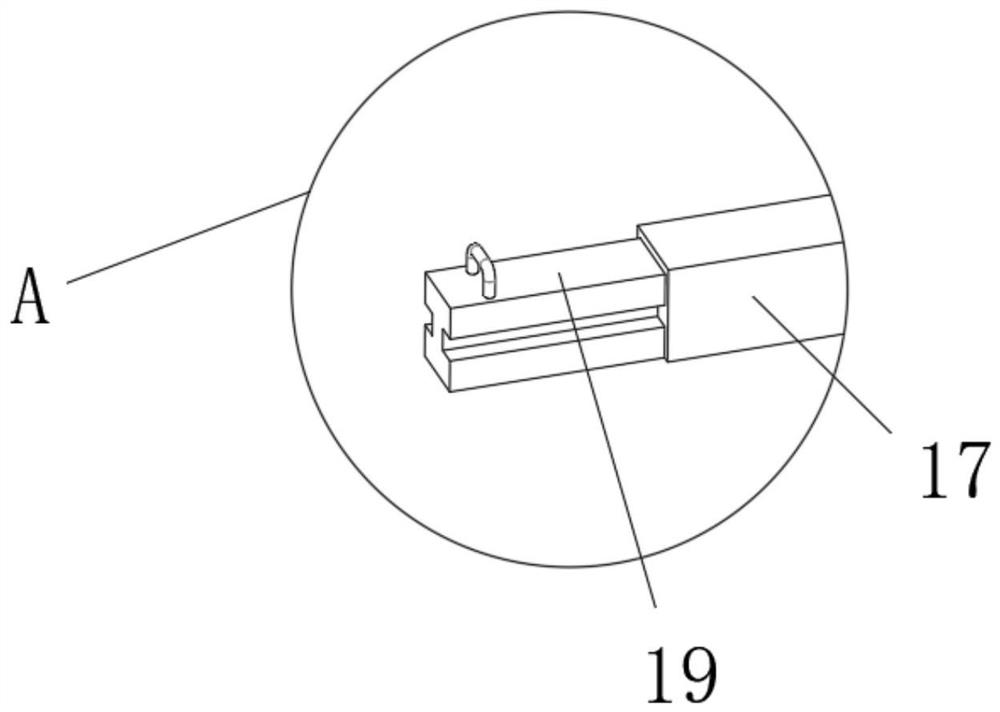

[0068] Wherein, one end of the bottom beam 11 is welded with a first square support pipe 16, the bottom beam 11 away from the other end of the second square support pipe 17 is welded with a second square support pipe 17, the

Example Embodiment

[0092] Example 2

[0093] More specific, such as Figure 1 、 Figure 6 、 Figure 7 and Figure 12 As shown, the present embodiment differs from Example 1 in that the electronic control input end of the first lighting box 43 is electrically connected to the electronic control output terminal of the PLC controller 311 by a wire, and the electronic control input terminal of the second lighting box 53 is electrically connected to the electronic control output terminal of the PLC controller 311 through a wire.

[0094]By using the above technical solution, the on-site construction personnel working on the base plate 31 in the night construction operation, by operating the PLC controller 311, the first light box 43 and the second light box 53 of the lighting range, lighting time, and lighting intensity of the lighting to meet the needs of night construction operations.

Example Embodiment

[0095] Example 3

[0096] More specific, such as Figure 10 、 Figure 14-Figure 17 As shown, the difference between the present embodiment and Example 2 is that both sides of the inner wall of the first support seat 12 are molded with a first slide rail 121, both sides of the first sliding plate 14 are opened with a first chute 141, the first slide rail 121 is installed within the first chute 141, and is connected to the first chute 141 slide, the inner wall of the second support seat 13 is formed on both sides of the second rail 131, the second slide plate 15 is opened on both sides of the second chute 151, the second slide rail 131 is installed within the second chute 151, And with the second chute 151 sliding connection; the first square support pipe 16 on both sides of the inner wall are formed with a third slide 161, the first square steel 18 on both sides of the outer wall are opened with a third chute 181, the third rail 161 is installed in the third chute 181, and connected wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap