Die changing device of five-beam-four-column power press equipment lower punch

A column press and medicine machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of difficulty in lifting and dragging out the press, time-consuming and labor-intensive lower punches, damage to molds, etc., to achieve simple structure, save labor and time when replacing punches , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

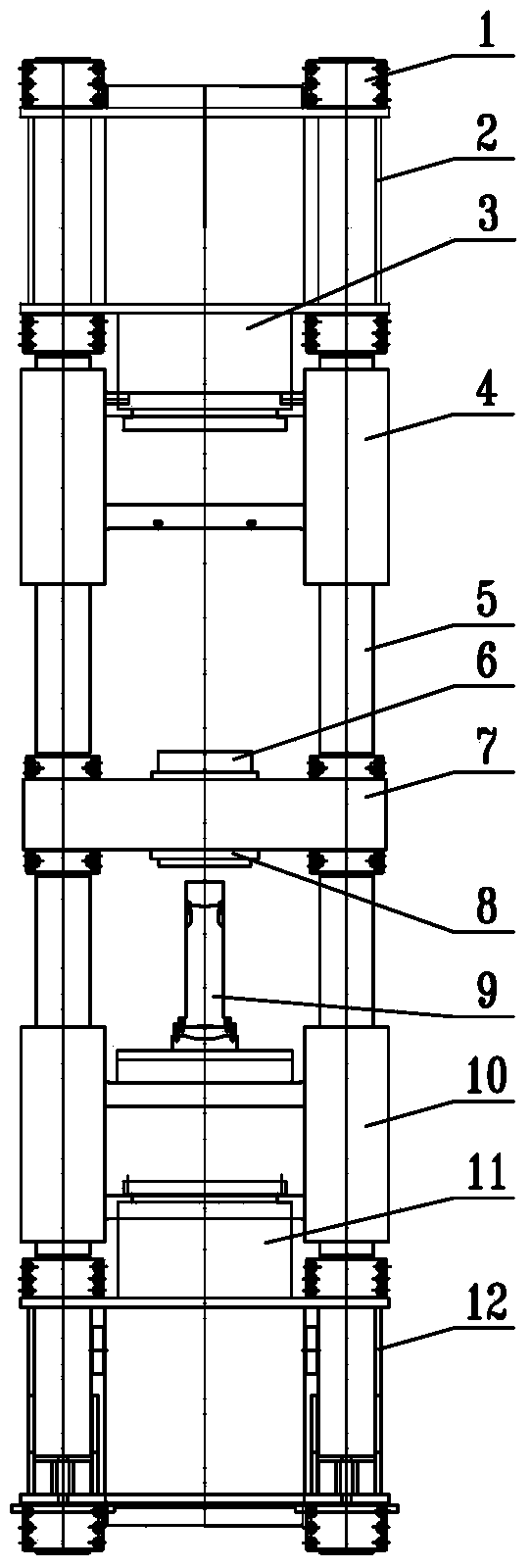

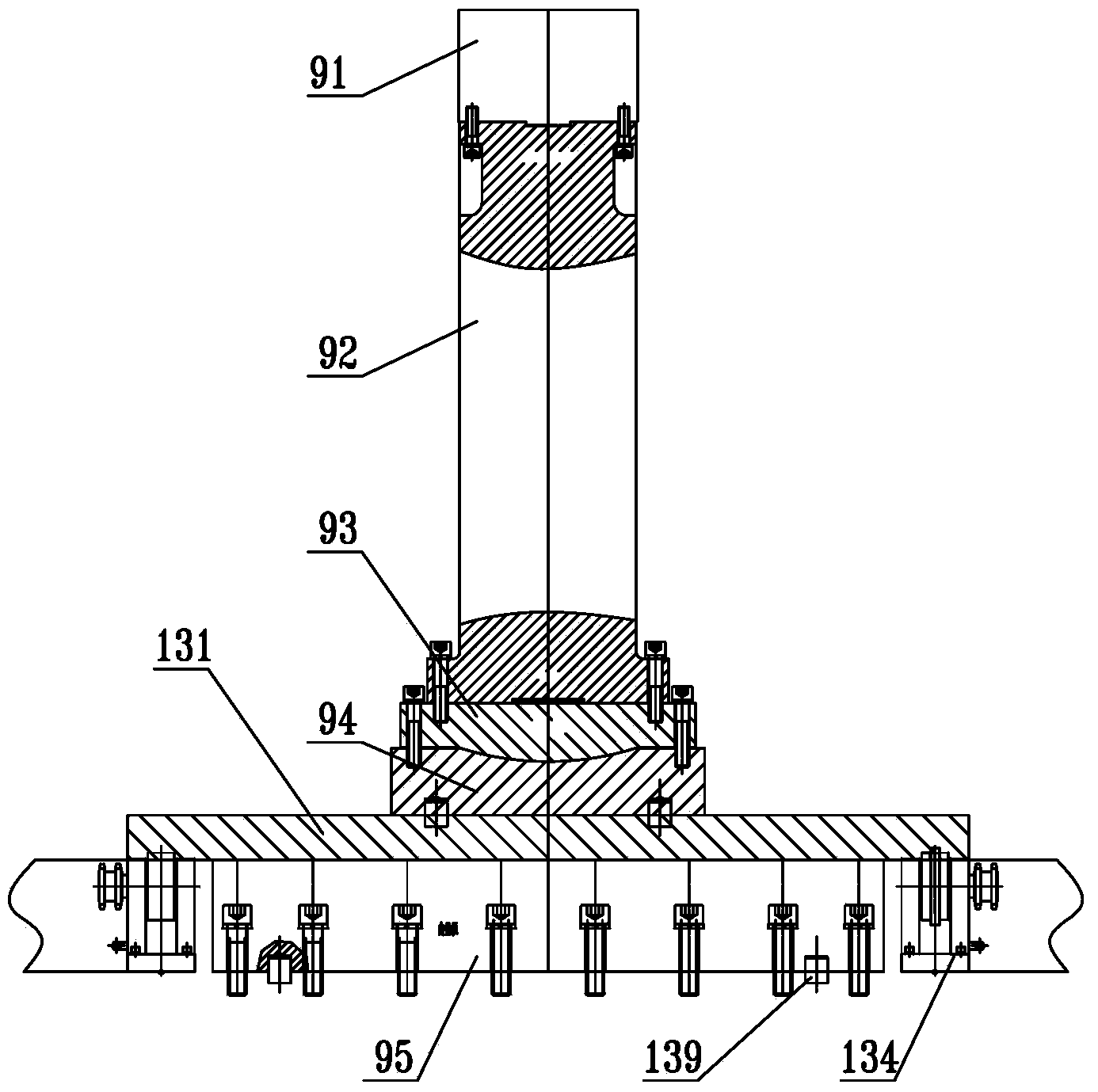

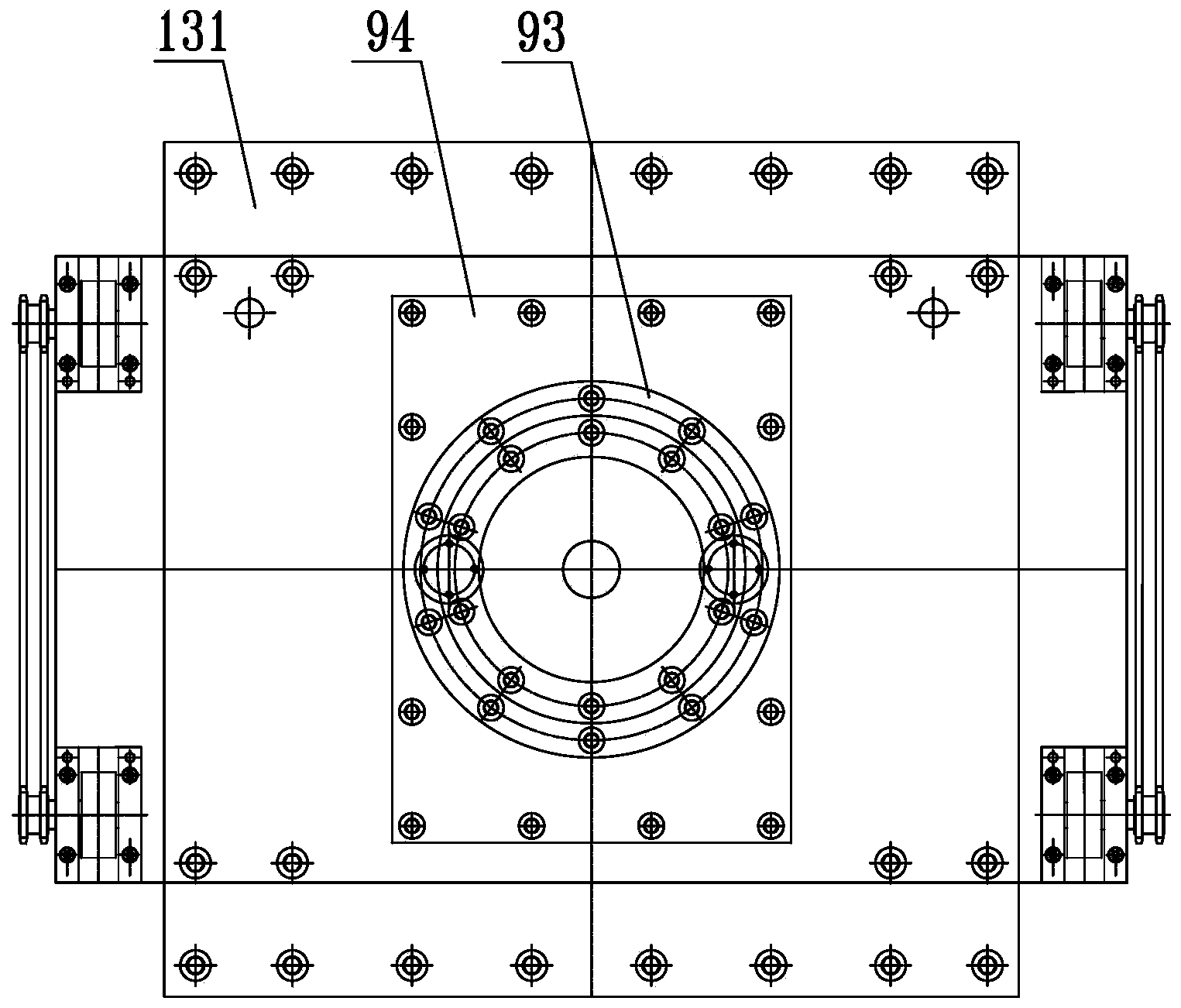

[0016] like figure 1 As shown, the five-beam four-column hydraulic press of this embodiment includes an upper nut 1, an upper beam 2, an upper oil cylinder 3, an upper slider 4, a column 5, a cylindrical mold 6, an intermediate fixing table 7, a lower nut 8, and a lower punch Head 9, lower slider 10, lower oil cylinder 11 and lower beam 12, the upper beam 2, upper slider 4, column 5, middle fixed platform 7, lower slider 10, lower beam 12 are arranged in sequence, and the upper nut 1 is fixed At the top of the upper beam 2, the upper cylinder 3 is connected with the upper slider 4, the cylindrical mold 6 is set in th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap