Waste chip recovery lathe for practice teaching

A practical teaching, lathe technology, applied in the direction of metal processing machinery parts, maintenance and safety accessories, presses, etc., can solve the problems of difficult waste cleaning and no protective measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

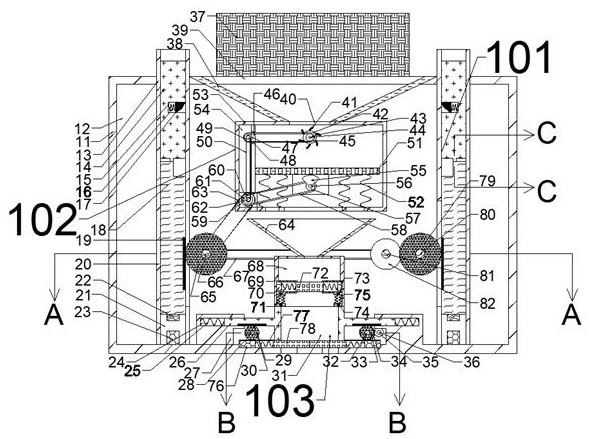

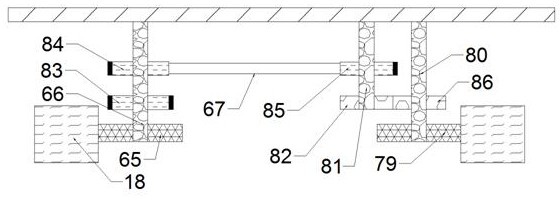

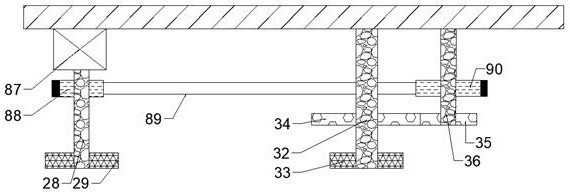

[0016] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] combined with Figure 1-4 The waste recovery lathe for practical teaching includes a box body 11, an empty compartment 12 is arranged in the box body 11, a safety guarantee mechanism 101 is arranged in the empty compartment 12, and the safety guarantee mechanism 101 includes Two safety boxes 20, the two safety boxes 20 are left and right symmetrical with the center line of the empty warehouse 12 as the center, the safety boxes 20 are fixedly connected to the lower inner wall of the empty warehouse 12 and their upper ends extend out of the outer space, Each of the safety boxes 20 is provided with an upwardly-opening security compartment 21, the lower inner wall of the security ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap