Method for operating a bending machine

A technology for bending machines and operators, applied in the direction of press machines, computer control, general control systems, etc., can solve problems such as operating errors, unqualified, hindering workpiece application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As an introduction, it should be noted that in different described embodiments, the same parts have the same reference numerals or the same component names, wherein the disclosure contained in the entire specification can be referred to by reference to the same drawings. Mark or the same part of the same part name. Furthermore, selected position indications such as top, bottom, side, etc. in the description relate to the directly described and depicted figures, and in the event of a position change, these position indications shall be transferred mutatis mutandis to the new position.

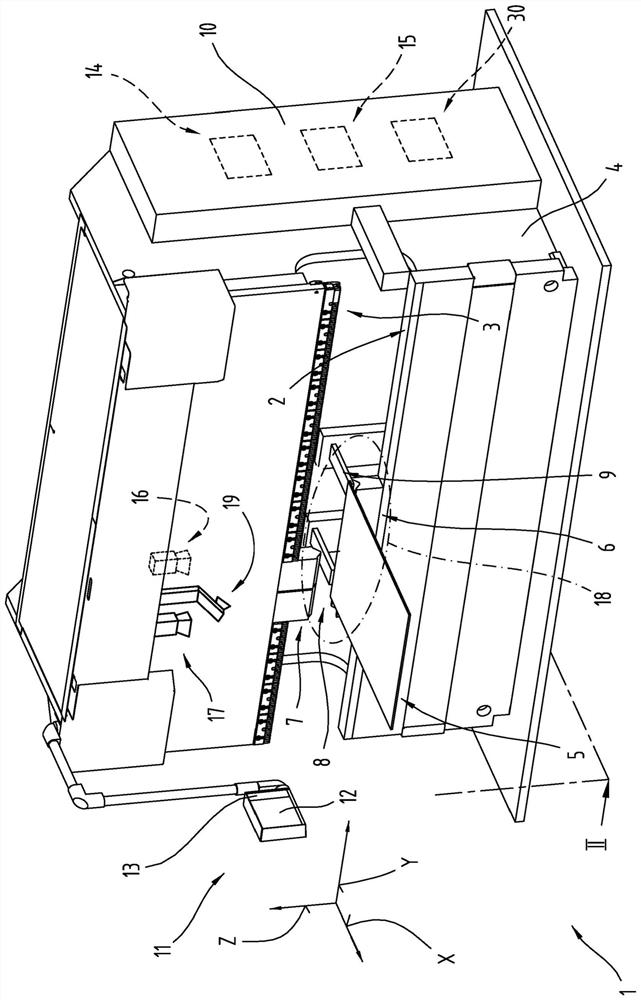

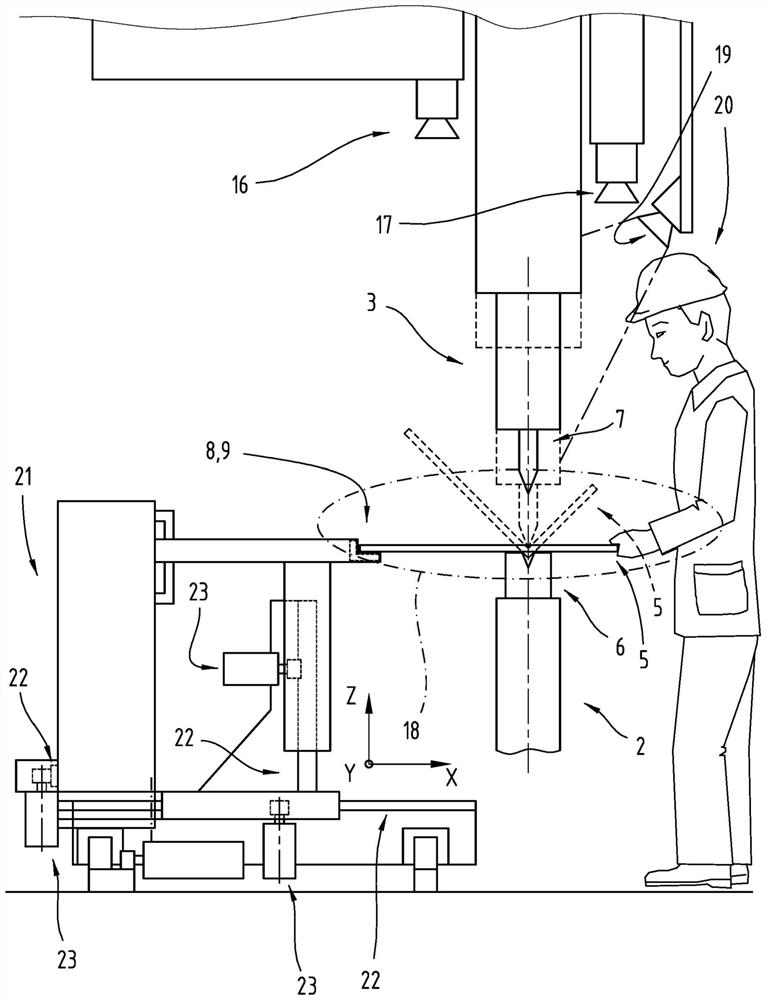

[0029] figure 1 A press brake 1 is shown as an example of a manufacturing plant or workpiece handling machine. The press brake 1 has a lower pressing beam 2 and an upper pressing beam 3 in a known manner. The two pressure beams 2, 3 are held by a frame 4 on which the lower pressure beam 2 is fixed (ie, stationary). The fixed hold-down beam 2 is therefore often also referred to as a table

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap