High-frequency electric-heating rolling strip

A technology of rolling belt and high-frequency electricity, which is applied in the field of rolling belt, can solve the problems of long heating time, low heating efficiency, large heat energy loss, etc., achieve uniform heating, overcome the effect of heating method and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

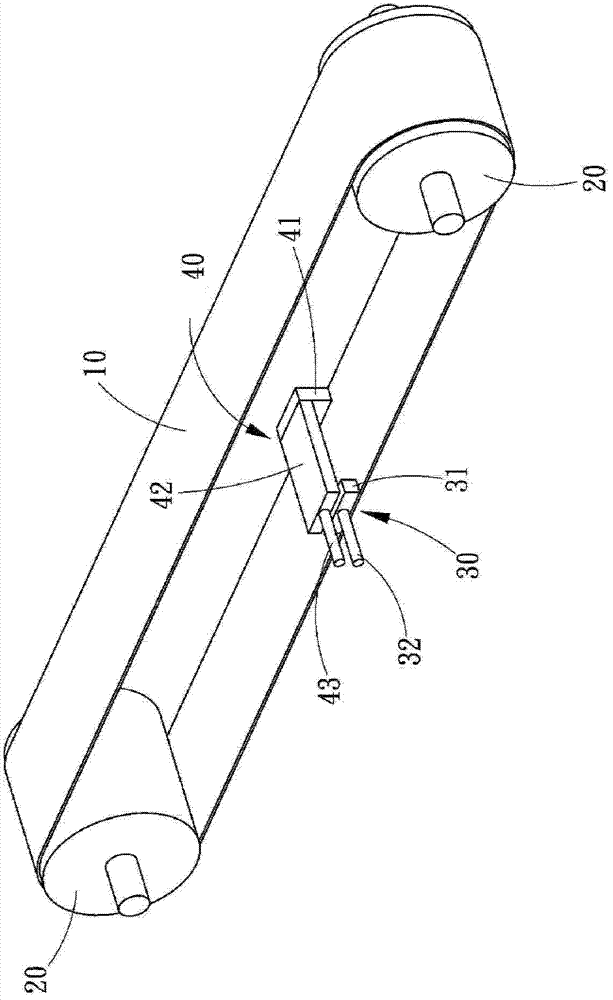

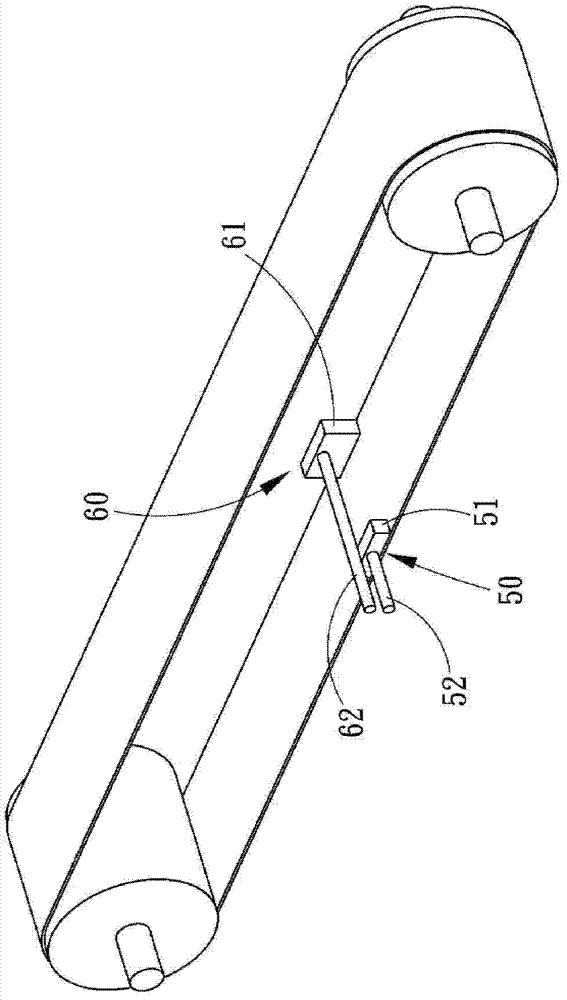

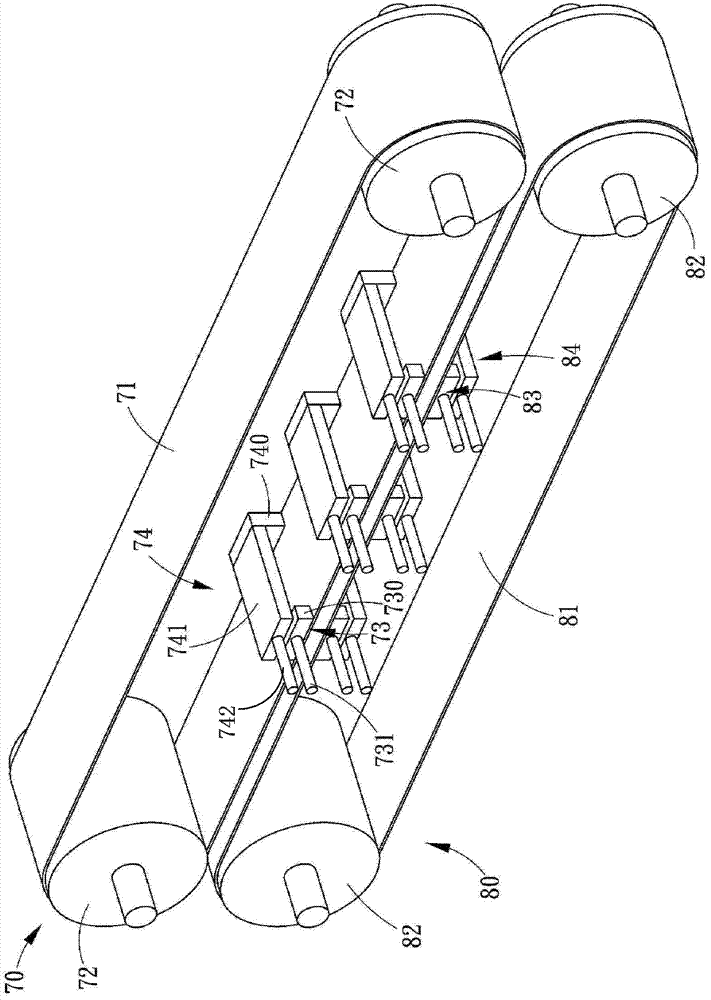

[0016] Please refer to figure 1 shown, figure 1 It is an example of a set of rolling belts. The object to be processed can be directly placed on the worktable, and the surface of the rolling belt that generates heat can be used to heat the object to be processed. The high-frequency electric heating rolling belt of the present invention is composed of a rolling belt body 10, two rollers 20 and a heating device. The rolling belt body 10 is wound on two rollers 20, and the outer surface of the rolling belt body 10 is in contact with the object to be processed, so that the object to be processed is heated. When the roller 20 rolls, due to the friction force between the roller 20 and the rolling belt body 10 , the rolling belt body 10 is driven by the roller 20 to move. The rolling belt body 10 has conductivity, and the heating device is connected to a high-frequency AC power supply.

[0017] The heating device includes at least two conductive components 30, 40 connected to differe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap