Upper die for oil press

A technology of hydraulic press and medium pressure head, applied in the field of hydraulic press, can solve the problems of heavy upper die, waste of cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

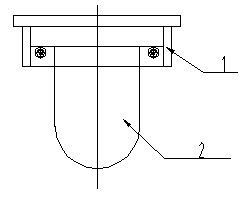

[0015] like figure 1 An upper mold for a hydraulic press shown in -3 includes an upper mold 2 and an upper mold base 1. The middle part of the upper mold 2 has a protrusion, and the protrusion is a cone or cylinder with a hemispherical top. The upper mold 2 and the upper mold The base 1 is fixed by bolts.

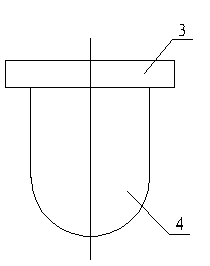

[0016] The upper die 2 also includes a middle pressure head and a "T"-shaped connector 3. The middle pressure head is a raised part of the upper die 2. There is a through hole in the middle of the middle pressure head. The size of the through hole is vertical to the "T"-shaped connector 3. Partially matched, the middle pressure head and the "T" type connector 3 are connected by bolts.

[0017] The upper mold base 2 is a steel plate, and the two edges protrude upwards, and the protruding part is fixed with the horizontal part of the "T" type connector 3 with bolts.

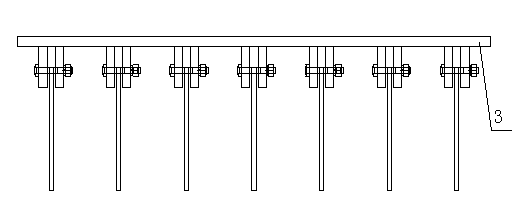

[0018] Multiple "T"-shaped connecting pieces 3 are fixed on one piece of hydraulic press, and each "T"-shaped

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap