Asphalt mortar and aggregate adhesion evaluation method

An evaluation method, the technology of asphalt glue, applied in the direction of analyzing materials, strength characteristics, and using stable tension/pressure to test material strength, etc., can solve interface difficulties, different polishing degrees, and inability to accurately evaluate asphalt mixture resistance to water damage Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The significance of the influence of 400 SiC polished stone slabs on the results of the asphalt pull-out test is obtained by the following steps:

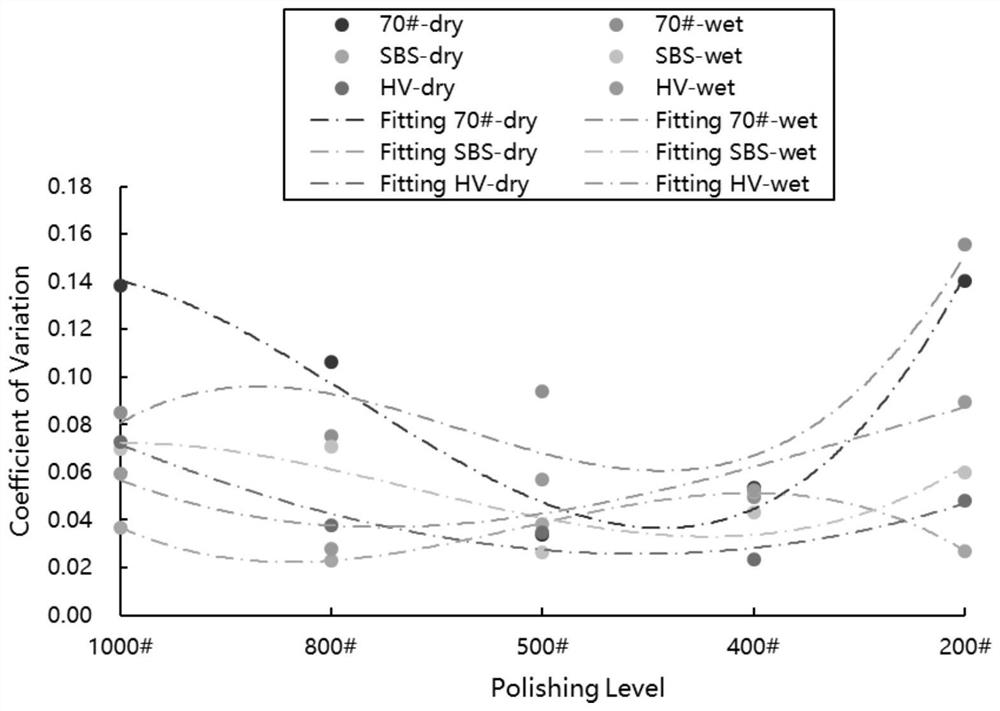

[0035] The pull-out test was carried out by combining 70# base asphalt, SBS modified asphalt and high-viscosity asphalt with basalt slabs with different polishing degrees, and the test was carried out after drying and water bath for 24 hours. The discreteness of parallel test results is as attached figure 1 As shown by the coefficient of variation, the coefficient of variation of 400SiC slate is the smallest. The significance of the degree of polish is shown in Table 1, and the degree of polish has a significant effect on variability.

[0036] Table 1 Analysis of variance for the influence of polishing degree on the coefficient of variation

[0037]

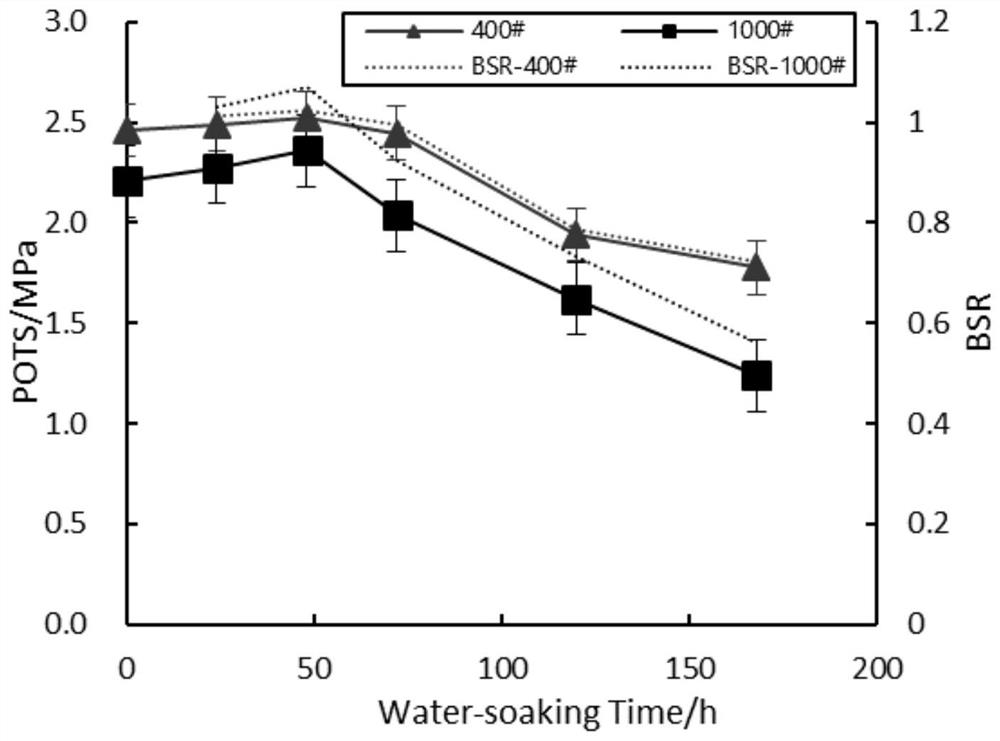

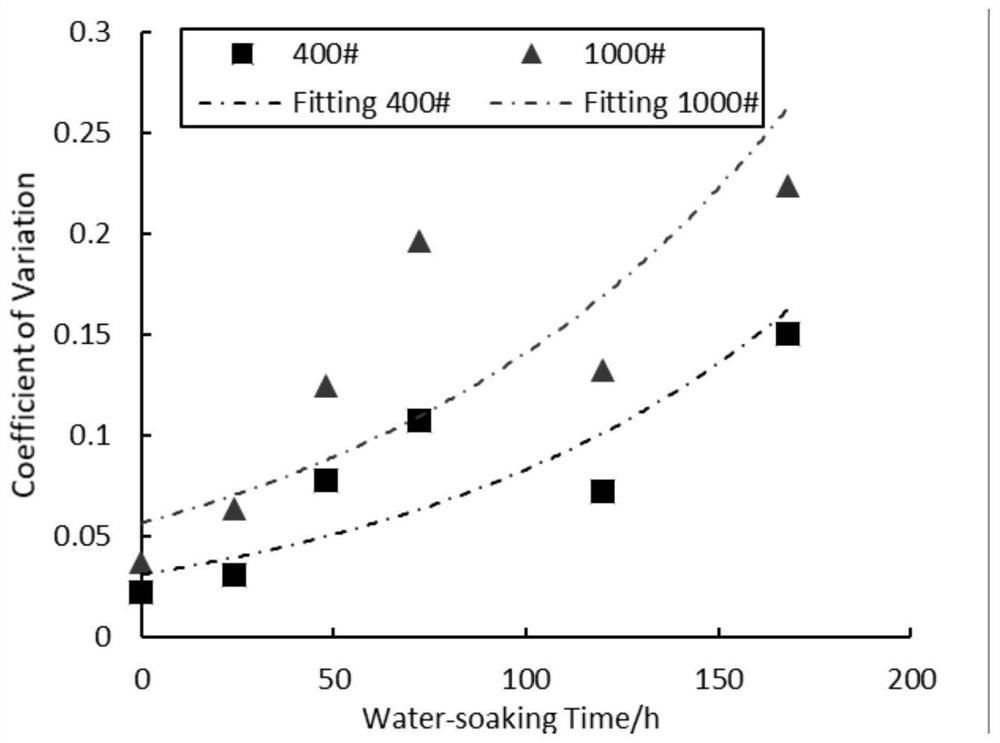

[0038] On the basis of the 70# matrix asphalt test piece, the length of the water bath was extended to measure the pull-out strength of 1 day, 2 days, 3 days, 5 days and 7 da

Embodiment 2

[0042] The significant effect of 400 SiC polished slate on the results of the mortar pull-out test is obtained through the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap