Novel polishing machine

A polishing machine, a new type of technology, applied in the field of machinery, can solve the problems of large power consumption, increased procedures, time-consuming and laborious, etc., and achieve the effect of reasonable structural design, convenient mobile use, and reduced operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

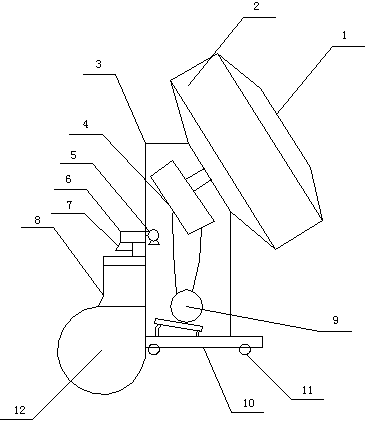

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a feed port 1, a polishing cylinder 2, a body 3, a reducer 4, a vacuum pump 5, a suction fan 6, a waste port 7, a discharge port 8, a motor 9, a base 10, Roller 11 and receiving bag 12, a polishing drum 2 is arranged on one side of the body 3, a feeding port 1 is arranged above the polishing drum 2, a reducer 4 is arranged inside the body 3, and the reducer 4 is connected to the motor 9 through a belt , One side of the reducer 4 is provided with a vacuum pump 5, the vacuum pump 5 is connected with the suction fan 6, a waste material port 7 is provided below the suction fan 6, a material discharge port 8 is provided below the waste material port 7, and the bottom of the material discharge port 8 is set Receive material bag 12, and the bottom of body 3 is provided with base 10, and the bottom of base 10 is provided with roller 11.

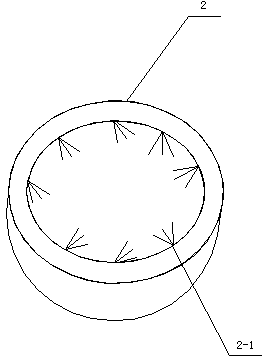

[0010] Several polishing brushes 2-1 are u

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap