Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Material hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardness: A material’s ability to withstand friction, essentially abrasion resistance, is known as hardness. Diamonds are among the hardest substances known to man, it is incredibly difficult to scratch a diamond.

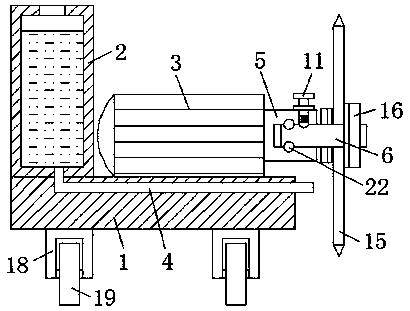

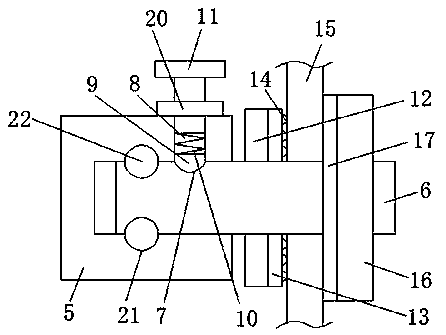

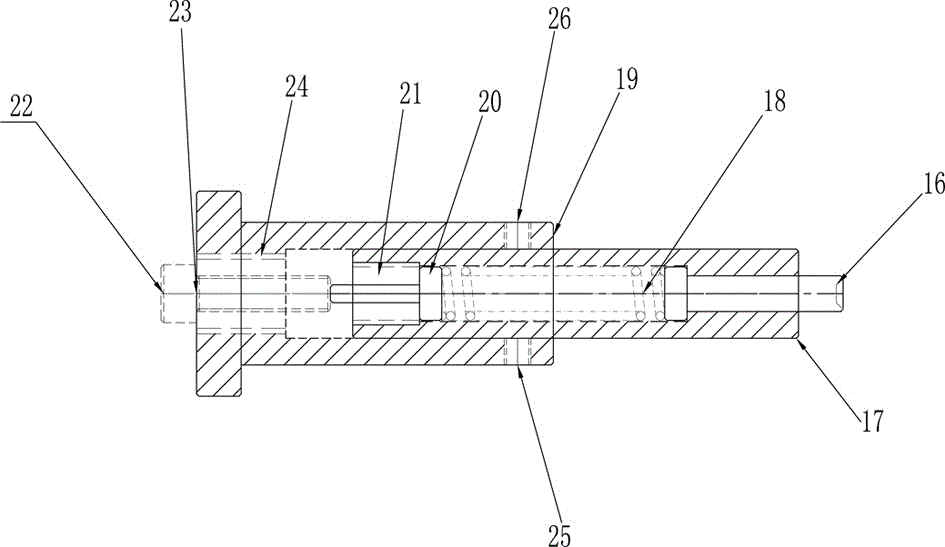

Anti-breaking grooving machine for construction site

Owner:WUXI KONSTANT POWER TECH CO LTD

Servo motor driven type in-die variable-speed tapping machine with screw tap detection device

ActiveCN106041228AThread cutting machinesMeasurement/indication equipmentsMaterial hardnessMotor drive

Owner:DONGGUAN FOUROCEAN MACHINERY TOOLS

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap