Combined compressor multielement penetration compound layer piston ring

A multi-component co-infiltration and compound layer technology, which is applied in the field of compressors, can solve the problems of affecting the sealing performance of compressors, failure to obtain initial elasticity, large gaps, etc., and achieve the effect of improving service life, good performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

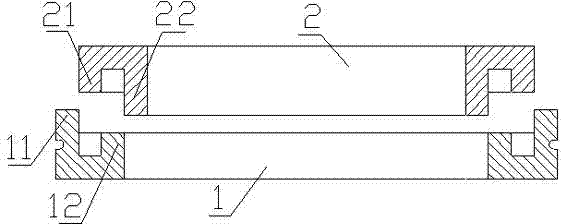

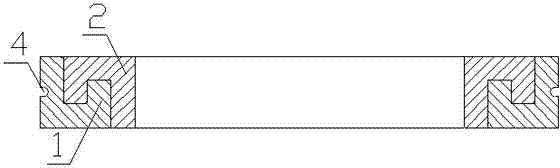

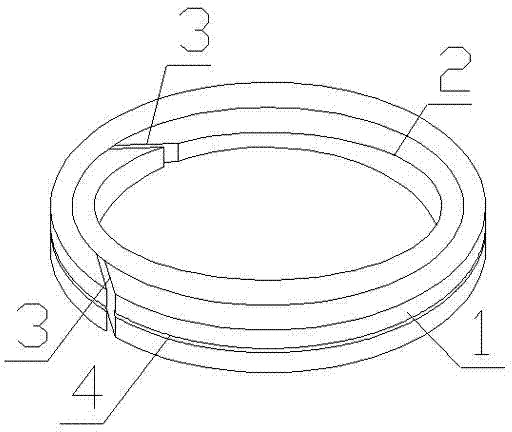

[0018] Such as figure 1 As shown, a combined multi-component compound layer piston ring of a compressor includes a main piston ring 1 and an inner auxiliary piston ring 2 . The main piston ring 1 and the inner auxiliary piston ring 2 have the same height, and both include a body made of polytetrafluoroethylene and polyether ether ketone filled in the body. The primary piston ring 1 and the inner secondary piston ring 2 are provided with a cutout 3, and the two cutouts 3 are arranged in a staggered manner. The middle part of the upper end surface of the main piston ring 1 is recessed inward to form a groove, forming a main piston ring 1 with an outer ring side 11 and an inner ring side 12, wherein the height of the outer ring side 11 of the main piston ring 1 is 12 on the inner ring side 2 times the height value, the height value of the inner ring side 12 is equal to the distance value between the outer ring side 11 and the inner ring side 12, and is also equal to the thickness v

Embodiment 2

[0021] When the primary piston ring 1 and the inner auxiliary piston ring 2 in the first embodiment are assembled, the inner ring side 12 of the main piston ring 1 snaps into the groove between the outer ring side 21 and the inner ring side 22 of the inner auxiliary piston ring 2 Inside, the outer ring side 21 of the inner secondary piston ring 2 snaps into the groove between the outer ring side 11 and the inner ring side 12 of the primary piston ring 1 . Due to the height value of the outer ring side 11 on the main piston ring 1, the height value of the inner ring side 12, the distance value between the outer ring side 11 and the inner ring side 12 and the groove between the outer ring side 11 and the inner ring side 12 The ratio of the thickness value of the ring is: 2:1:1:1, the height value of the outer ring side on the inner auxiliary piston ring 2, the height value of the inner ring side, the distance value between the outer ring side and the inner ring side and the oute

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap