Mn<4+> doped fluoroaluminate red fluorescent powder as well as preparation method and application thereof

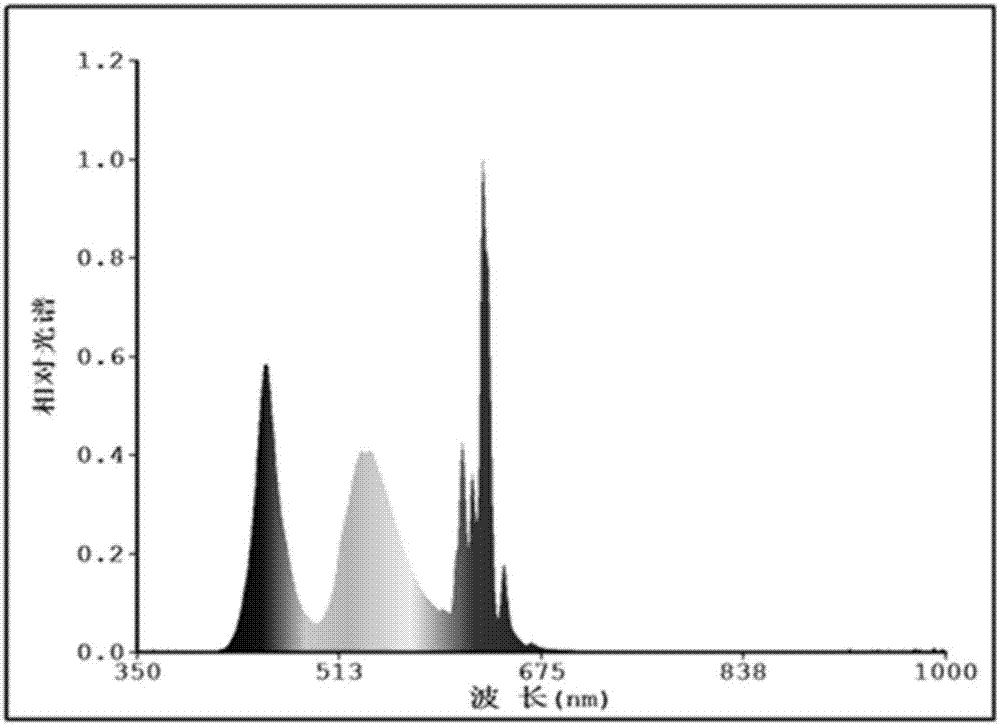

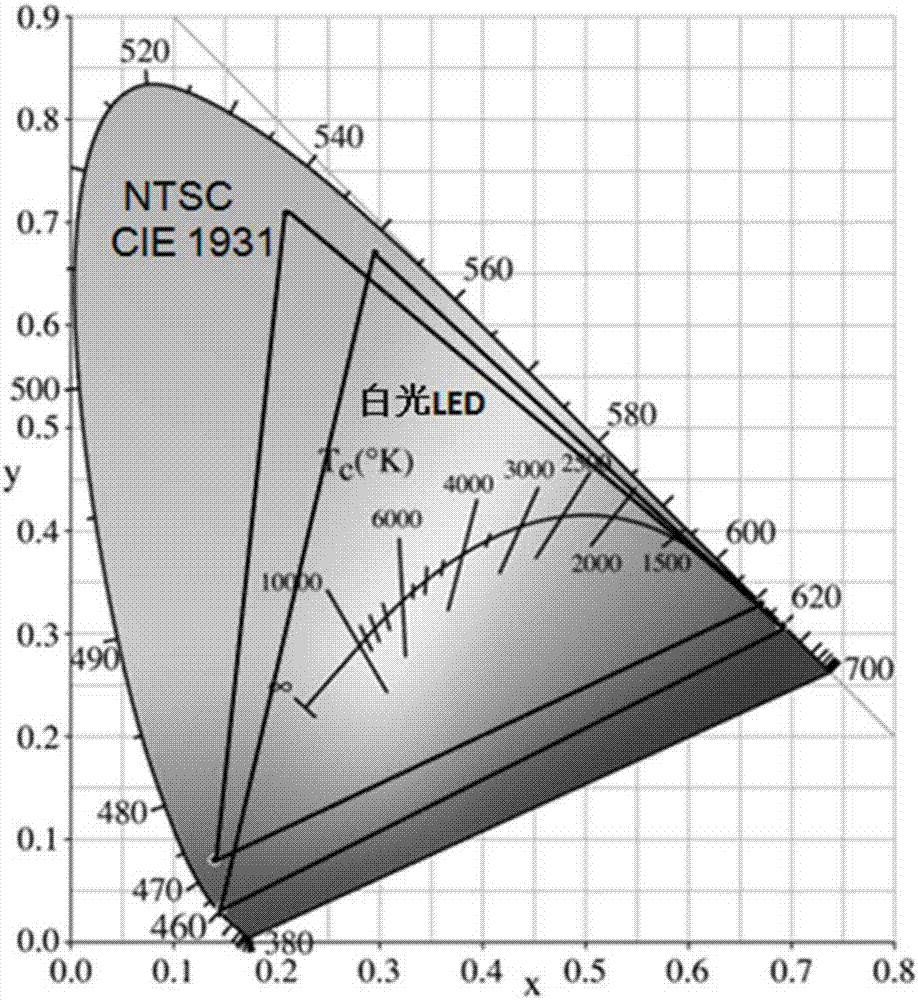

A red phosphor, fluoroaluminate technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as instability, and achieve the effects of phase purity, wide color gamut, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a kind of Mn 4+ The preparation method of doped fluoroaluminate red fluorescent powder is characterized in that the steps are as follows: add hydrofluoric acid and water into a polytetrafluoroethylene container, and then add K 2 MnF 6 , stir to make it dissolve and then add KF; after KF dissolves, add K 3 AlF 6 Continue to stir until K 3 AlF 6 Continue stirring for 30 minutes after complete dissolution; stop stirring for 6 hours, filter with suction, take the filter cake and dry it under vacuum at 70°C to obtain the Mn 4+ Doped fluoroaluminate red phosphor. K 3 AlF 6 Can not exist stably in aqueous solution, partly decomposed into K 2 AlF 5 ·H 2 O, add KF·2H to the reaction system 2 O helps suppress K 3 AlF 6 decomposition to synthesize pure phase K 3 AlF 6 .

[0025] KF and K 3 AlF 6 The molar ratio is 0.4:1, K 2 MnF 6 with K 3 AlF 6 The molar ratio is 0.02:1.

[0026] The mass concentration of described hydrofluoric acid is 10%, and the mass concen

Embodiment 2

[0028] a kind of Mn 4+ The preparation method of doped fluoroaluminate red fluorescent powder is characterized in that the steps are as follows: add hydrofluoric acid and water into a polytetrafluoroethylene container, and then add K 2 MnF 6 , stir to make it dissolve and then add KF; after KF dissolves, add K 3 AlF 6 Continue to stir until K 3 AlF 6 Continue stirring for 30 minutes after complete dissolution; stop stirring for 24 hours, filter with suction, take the filter cake and dry it under vacuum at 70°C to obtain the Mn 4+ Doped fluoroaluminate red phosphor. K 3 AlF 6 Can not exist stably in aqueous solution, partly decomposed into K 2 AlF 5 ·H 2 O, add KF·2H to the reaction system 2 O helps suppress K 3 AlF 6 decomposition to synthesize pure phase K 3 AlF 6 .

[0029] KF and K 3 AlF 6 The molar ratio is 6:1, K 2 MnF 6 with K 3 AlF 6 The molar ratio is 0.05:1.

[0030] The mass concentration of the hydrofluoric acid is 10% to 40%, the mass concentrat

Embodiment 3

[0032] a kind of Mn 4+ The preparation method of doped fluoroaluminate red fluorescent powder is characterized in that the steps are as follows: add hydrofluoric acid and water into a polytetrafluoroethylene container, and then add K 2 MnF 6 , stir to make it dissolve and then add KF; after KF dissolves, add K 3 AlF 6 Continue to stir until K 3 AlF 6 Continue stirring for 30 minutes after complete dissolution; stop stirring for 18 hours, filter with suction, take the filter cake and dry it under vacuum at 70°C to obtain the Mn 4+ Doped fluoroaluminate red phosphor. K 3 AlF 6 Can not exist stably in aqueous solution, partly decomposed into K 2 AlF 5 ·H 2 O, add KF·2H to the reaction system 2 O helps suppress K 3 AlF 6 decomposition to synthesize pure phase K 3 AlF 6 .

[0033] KF and K 3 AlF 6 The molar ratio is 2:1, K 2 MnF 6 with K 3 AlF 6 The molar ratio is 0.03:1. The mass concentration of hydrofluoric acid is 20%, and the mass concentration of solute in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap