Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Acrylate ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylates and methacrylates (the salts and esters of methacrylic acid) are common monomers in polymer plastics, forming the acrylate polymers. Acrylates easily form polymers because the double bonds are very reactive.

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

Gas layer formation materials

InactiveCN1735945APlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsAcenaphthyleneMethacrylate

The present invention provides gas layer formation material selected from the group consisting of acenaphthylene homopolymers; acenaphthylene copolymers; poly(arylene ether); polyamide; B-staged multifunctional acrylate / methacrylate; crosslinked styrene divinyl benzene polymers; and copolymers of styrene and divinyl benzene with maleimide or bis-maleimides. The formed gas layers are used in microchips and multichip modules.

Owner:HONEYWELL INT INC

Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

ActiveCN111138603AImprove compactnessImprove the level ofAnti-corrosive paintsPolymer sciencePtru catalyst

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

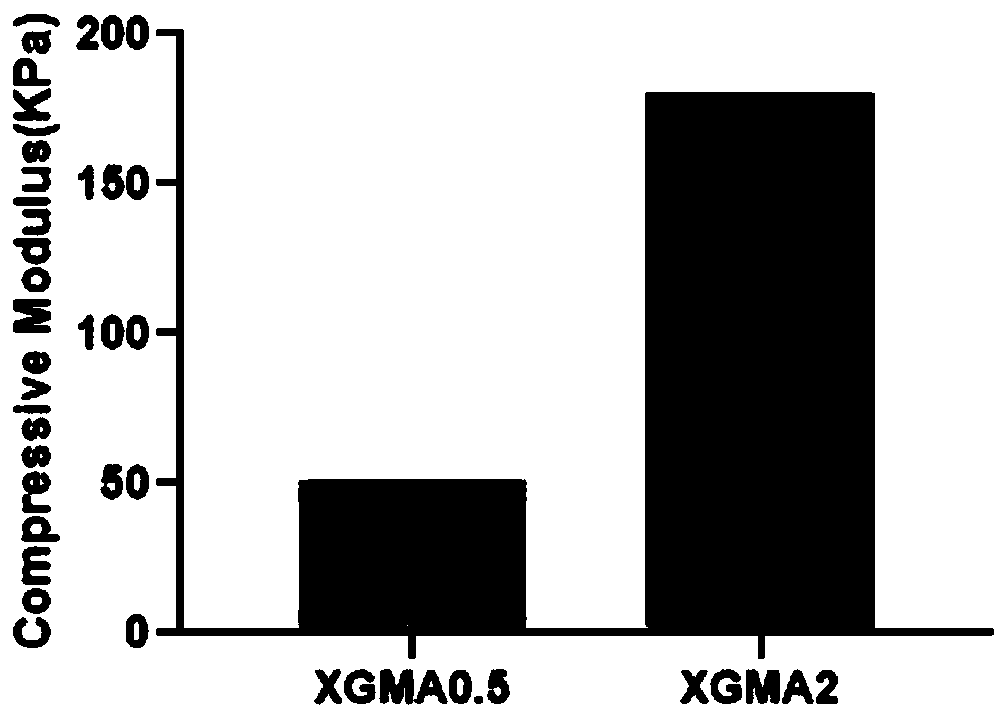

3D-printed xanthan glue gel scaffold and preparation method thereof

InactiveCN110680954AShape controllableHigh precisionTissue regenerationProsthesisCartilage cellsComputer printing

Owner:GUANGXI MEDICAL UNIVERSITY

Fiber coatings with low modulus and high critical stress

Fiber coatings with low Young's modulus, high tear strength, and / or high critical stress are achieved with coating compositions that include an oligomeric material formed from an isocyanate, a hydroxyacrylate compound and a polyol. The oligomeric material includes a polyether urethane acrylate and a di-adduct compound. The reaction mixture used to form the oligomeric material includes a molar ratio of isocyanate:hydroxy acrylate:polyol of n:m:p, where when p is 2, n is in the range from 3.0 to 5.0 and m is in the range from 1.50n-3 to 2.50n-5. Control of the n:m:p ratio leads to compositionsthat, when cured, provide coatings and cured products having high critical stress, high tear strength, and a high ratio of tear strength to Young's modulus.

Owner:CORNING INC

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Chlorella facial mask and preparation method thereof

PendingCN111557871ASpeed up metabolismPromote absorptionCosmetic preparationsToilet preparationsGlycerolEngineering

Owner:深圳市北清生物科技有限公司

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

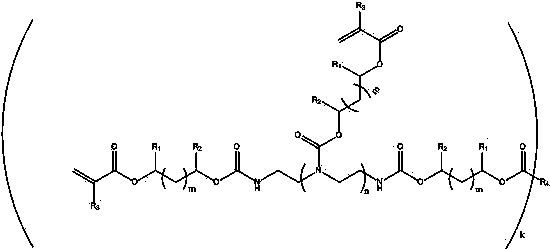

Nitrogen-containing multi-degree-of-functionality acrylate resin as well as preparation method and application thereof

ActiveCN104558600AImprove flexibilityHigh photopolymerization reactivityCarbamic acid derivatives preparationOrganic compound preparationPolymer scienceMeth-

Owner:LUCKY HUAGUANG GRAPHICS

Column insulator and manufacturing method thereof

ActiveCN114496424AImprove corrosion resistanceImprove wear resistanceSupporting insulatorsOrganic insulatorsEpoxyPolyvinyl alcohol

The invention discloses a column type insulator and a manufacturing method thereof, and relates to the technical field of insulators, the column type insulator comprises an insulator base body, and a first protective layer and a second protective layer which sequentially cover the surface of the insulator base body, the first protective layer is prepared from the following raw materials: silicon carbide, polyvinyl alcohol, fraxinus mandshurica clay / glass fiber composite material, wollastonite and diatomite / nano calcium carbonate composite material; the second protective layer is prepared from the following raw materials: a modified epoxy resin / montmorillonite composite material, modified hydrophobic silicon dioxide, polyacrylate and silicone acrylic emulsion. The invention has the beneficial effects that the first protection layer and the second protection layer are formed on the surface of the insulator substrate, so that the corrosion resistance, the wear resistance, the weather resistance and the anti-pollution flashover performance of the insulator can be improved.

Owner:PINGXIANG HUACHUANG ELECTRIC CO LTD

Dental Polymerizable Core Build-Up Material of Separately Packed Type

ActiveUS20070249752A1Easy to operateImprove mechanical propertiesImpression capsTeeth fillingMethacrylateMeth-

Owner:KURARAY NORITAKE DENTAL

Preparation method of PET release film

ActiveCN113999625AImprove scratch resistanceImprove wear resistanceCoatingsFilm/foil adhesive release linersSilica nanoparticlesPolyvinyl alcohol

Owner:潍坊胜达科技股份有限公司

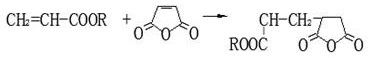

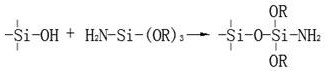

Polyacrylate grafted graphene oxide plugging agent and oil-based drilling fluid

InactiveCN114752365AImprove rheologyGood sealability and other aspects of performanceNanotechnologyDrilling compositionSilane compoundsPhysical chemistry

Owner:SOUTHWEST PETROLEUM UNIV

UV light-cured wood coating and preparation method thereof

InactiveCN114292572AAchieve complete deodorizationIncrease viscosityEpoxy resin coatingsPolymer scienceMeth-

The invention relates to the field of coatings, in particular to a UV light-cured wood coating and a preparation method thereof. The wood coating comprises the following components in parts by weight: 20-50 parts of resin, 20-40 parts of a monomer and 3-7 parts of an initiator, wherein the resin is epoxy acrylate or modified bisphenol A epoxy acrylate; the monomer is a mixture of trimethylolpropane triacrylate and diethylene glycol diacrylate; the initiator is a mixture of active amine and one or more of TPO, PBZ and OMBB. The wood coating provided by the invention can be cured under UV light, and the wood coating can realize complete odor removal; meanwhile, the wood coating has good viscosity, heat resistance, stability, leveling property and adhesive force, and relatively high curing speed.

Owner:PUYANG ZHANCHEN NEW MATERIALS CO LTD

Anti-yellowing leather finishing emulsion

InactiveCN111004556AEfficient captureAvoid oxidation reactionsCoatingsPolymer sciencePolypropylene glycol

The invention discloses an anti-yellowing leather finishing emulsion, which is prepared from the following raw materials in parts by weight: 65 to 80 parts of a modified polyacrylate resin, 1 to 3 parts of polydimethylsiloxane, 0.5 to 1.5 parts of an antifoaming agent, 0.5 to 1.5 parts of a leveling agent, 1.5 to 3 parts of silicon dioxide, 5 to 8 parts of polypropylene glycol and 10 to 20 parts of deionized water. According to the invention, the polyacrylate resin is modified, and the anti-yellowing modifier is prepared, is introduced into the polyacrylate resin in a cross-linking manner, andis firmly connected into the resin in a chemical bond manner, so that the polymers in a leather coating are effectively protected from an oxidation reaction, the good scrubbing resistance is achieved, and leather can resist yellowing for a long time.

Owner:王磊

High-temperature and high-pressure double-seal double-adjustment needle valve

InactiveCN111518448AImprove anti-corrosion performanceHigh strengthAnti-corrosive paintsFirming agentAcrylate ester

Owner:浙江方顿仪表阀门有限公司

PMMA-aluminum hydroxide-organophosphorus acrylic composite base material and preparation method thereof

Owner:ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

Self-healing branched polyethylene diamine hydrogel microcapsule composite material as well as preparation method and application thereof

Owner:中科南京绿色制造产业创新研究院 +1

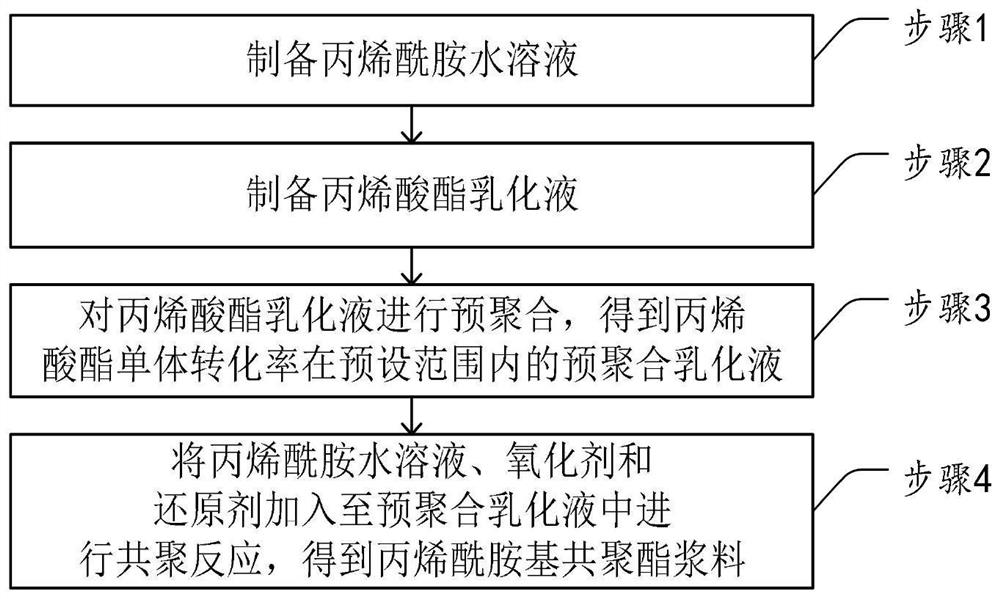

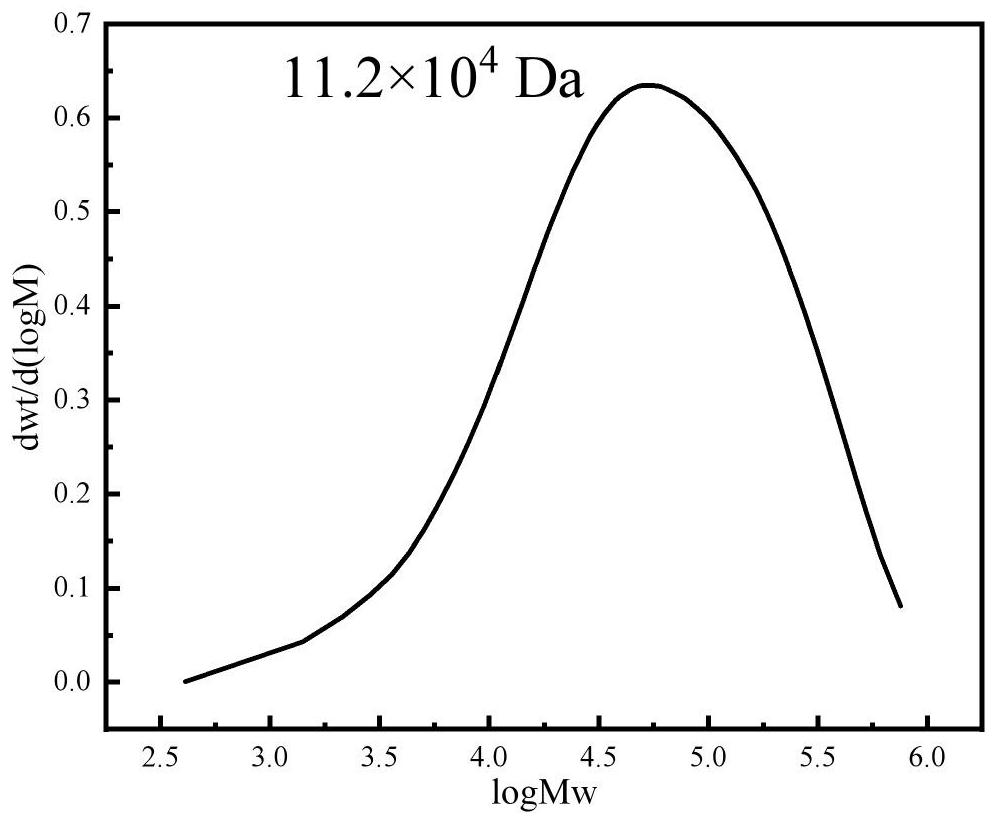

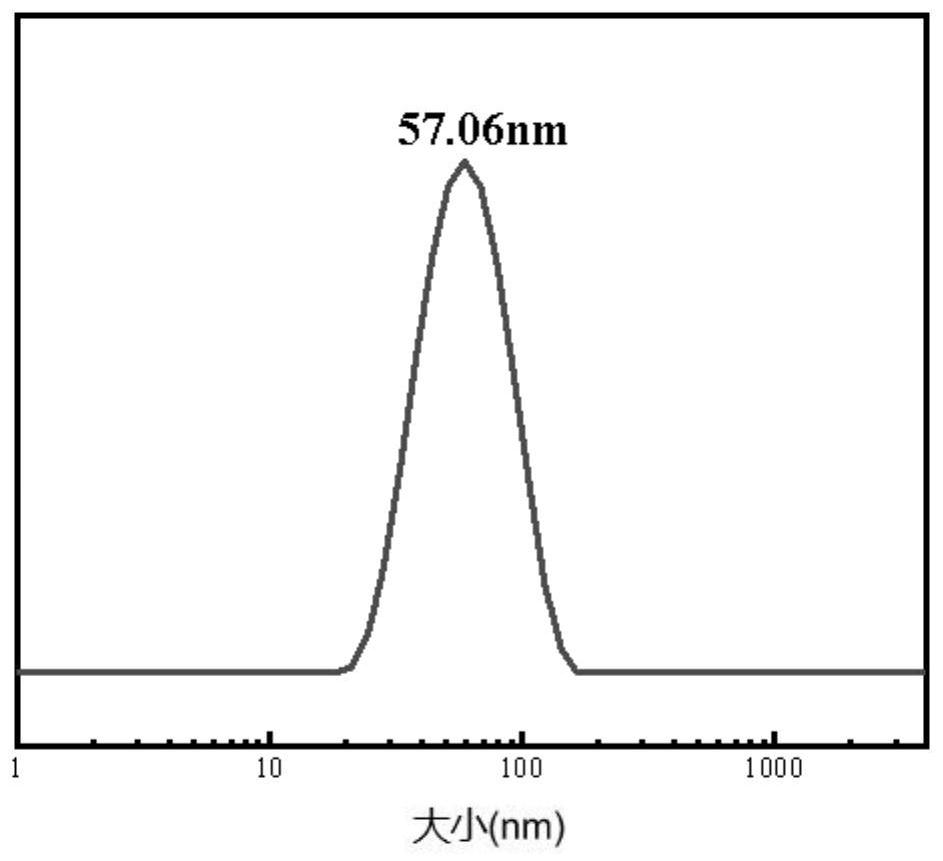

Acrylamido copolyester slurry and preparation method thereof

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap