Acrylamido copolyester slurry and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

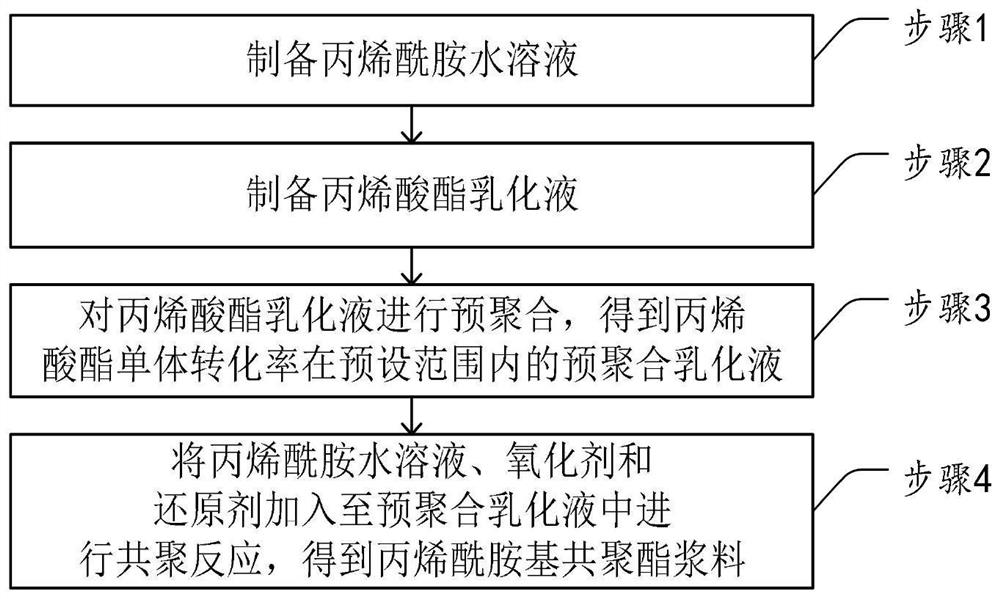

[0033] like figure 1 As shown, a first aspect of the present invention provides a method for preparing an acrylamide-based copolyester slurry, comprising:

[0034] Step 1. Prepare an aqueous solution of acrylamide.

[0035] The solid content of the acrylamide aqueous solution in the present invention is 15%-27%, preferably 18%-23%, more preferably 20%. The acrylamide aqueous solution within the solid content range has fast reaction rate and high conversion rate during subsequent copolymerization.

[0036] Step 2, prepare acrylate emulsion, specifically:

[0037] The acrylate is emulsified with an emulsifier to obtain an acrylate emulsion.

[0038] The emulsifier is an anionic sulfate emulsifier, such as sodium lauryl sulfate, alkylphenol polyoxyethylene ether formaldehyde condensate sulfate, fatty alcohol sulfate and the like.

[0039] The amount of emulsifier used is 2%-8% of the acrylate monomer, preferably 4%-6%, more preferably 5%. The metered emulsifier can reduce the c

Embodiment 1

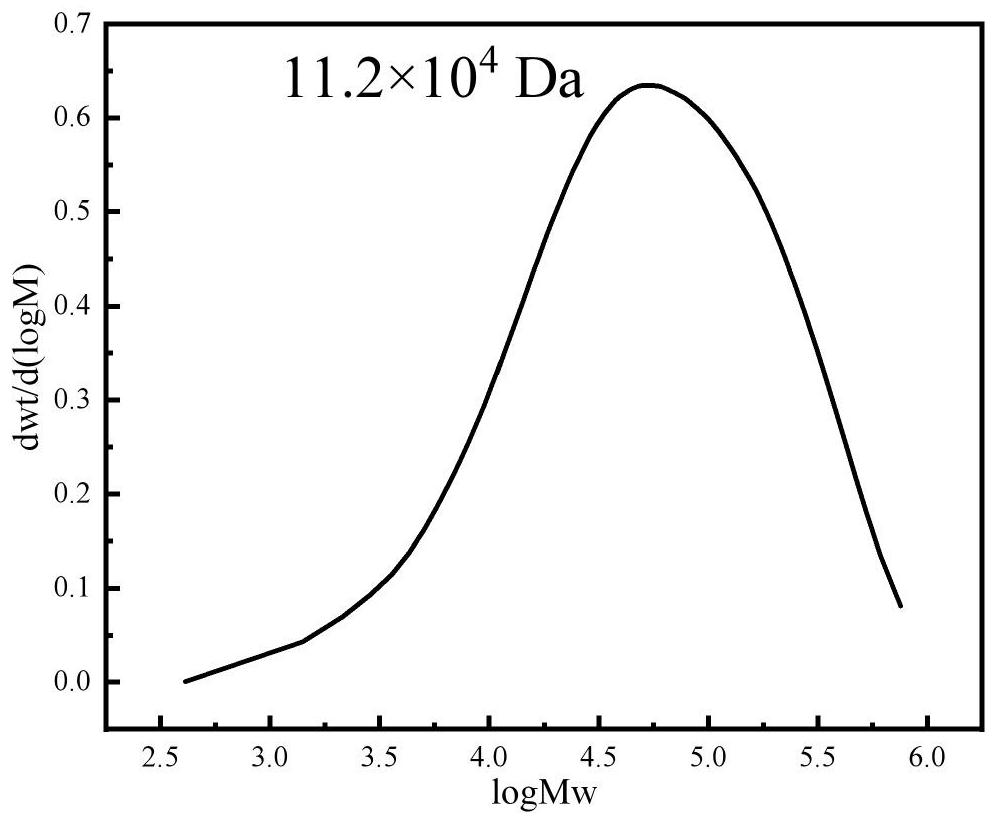

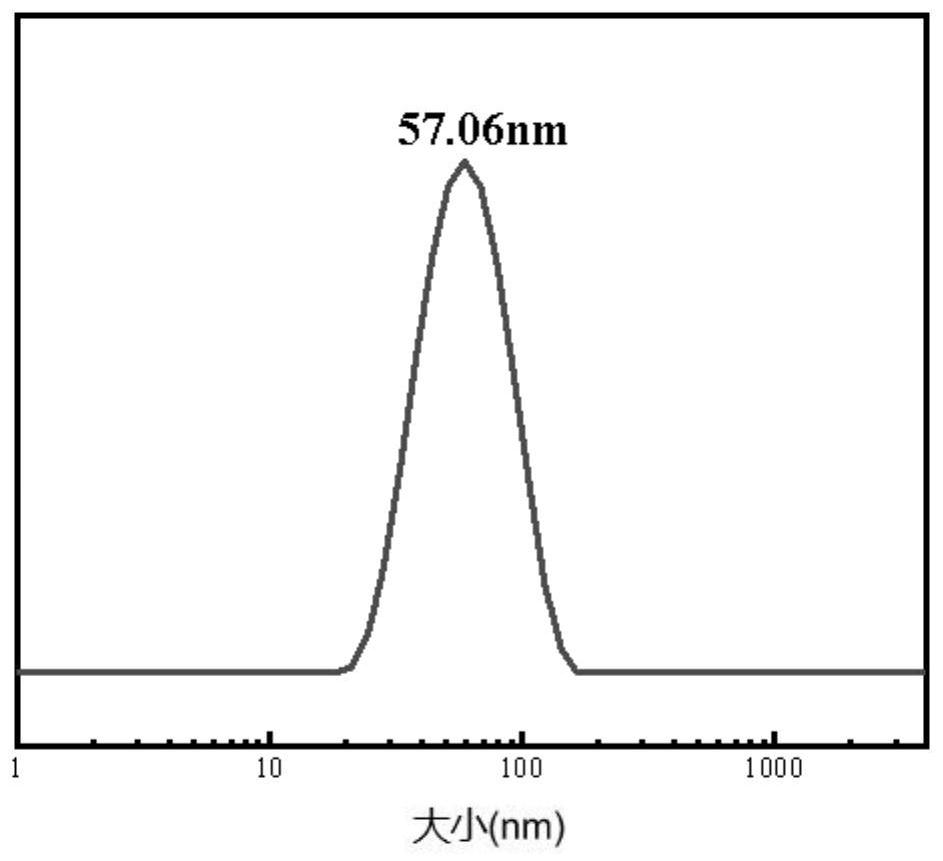

[0067] Prepare a methyl methacrylate emulsion with a solid content of 5%, the emulsifier dosage is 2%, and the emulsification is carried out at a speed of 500rpm for 30min; add an oxidant and a reducing agent to the emulsion, the oxidant is potassium persulfate, and the amount of the oxidant is 0.1%, the reducing agent is sodium bisulfite, and the reducing agent is 0.1%. The emulsion was placed in a reactor at 80° C., and prepolymerized for 40 minutes at a stirring speed of 200 rpm (to make the monomer conversion rate reach 13.79%); the solid content was 15% acrylamide aqueous solution, 0.5% oxidant and 0.1% oxidant. The reducing agent is added dropwise to the prepolymerized emulsion, wherein the oxidant is potassium persulfate, and the reducing agent is sodium hydrogen sulfite, and the polymerization is carried out at a stirring speed of 200 rpm for 1.5 hours to obtain acrylamide-based copolyester slurry, the molecular weight of which is as follows: figure 2 The shown is 110,00

Embodiment 2

[0069] Prepare a methyl methacrylate emulsion with a solid content of 3%, the emulsifier dosage is 3%, and the emulsification is carried out at a speed of 500 rpm for 30 minutes; add an oxidant and a reducing agent to the emulsion, the oxidant is ammonium persulfate, and the amount of the oxidant is 0.3%, the reducing agent is sodium hydrosulfite, the reducing agent is 0.1%, the emulsion is placed in an 85°C reactor and prepolymerized for 50min at a stirring speed of 200rpm (to make the monomer conversion rate reach 18.21%); 18% aqueous acrylamide solution, 0.4% oxidant and 0.2% reducing agent are added dropwise to the prepolymerized emulsion, wherein the oxidant is ammonium persulfate, the reducing agent is sodium hydrosulfite, and the polymerization is carried out at a stirring speed of 200rpm for 1.5h , to obtain acrylamide-based copolyester size, the molecular weight of which is 170,000-200,000, the viscosity is 750-900mpa·s, the particle size is 50-55nm, and the adhesion to p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap