Perforating device applied to plastic shells

A technology of punching device and plastic shell, which is applied in metal processing and other directions, can solve the problems of damage to plastic shell, uneven force of plastic shell, and poor fixation, so as to reduce the generation of scrapped parts and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

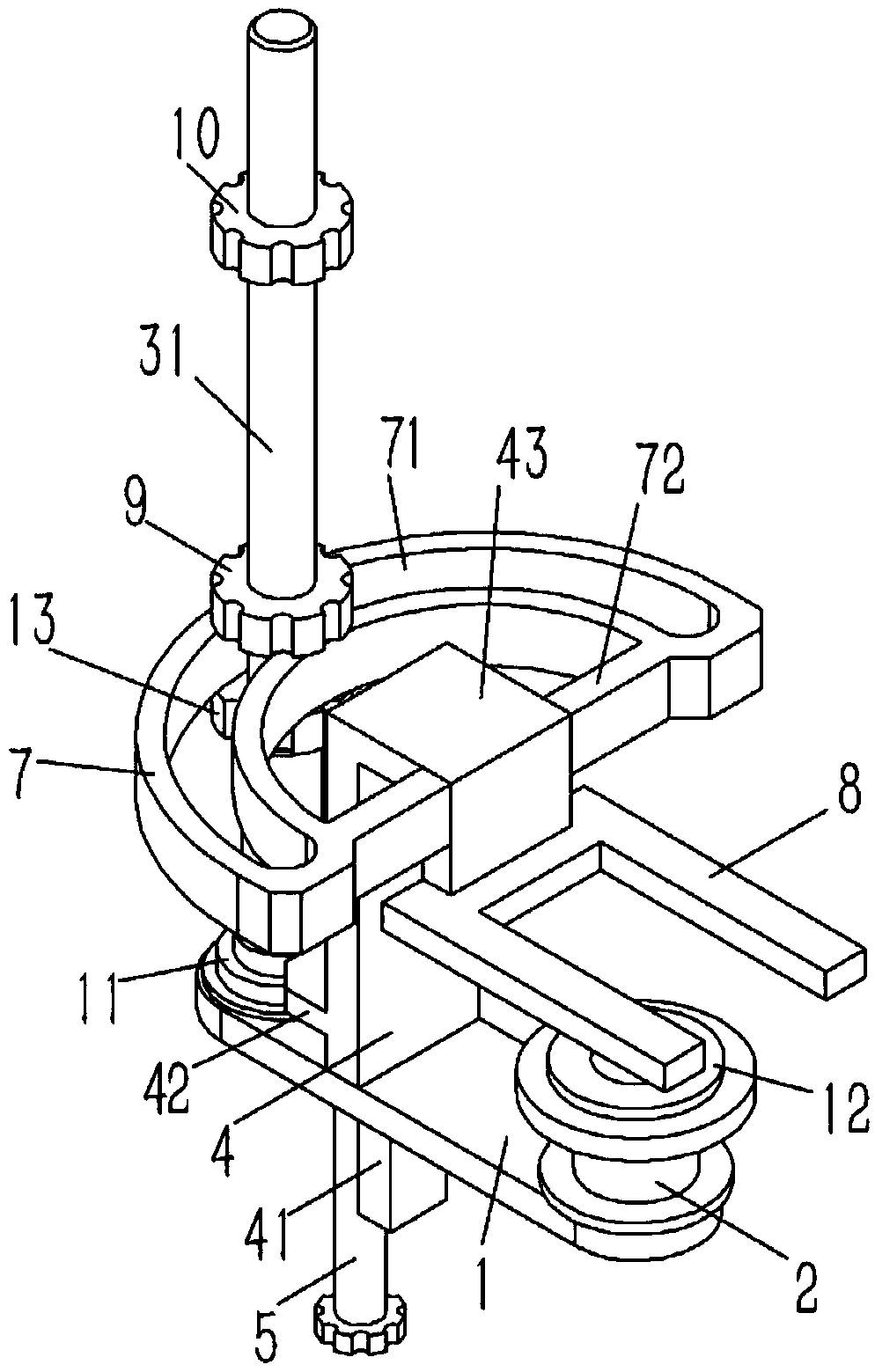

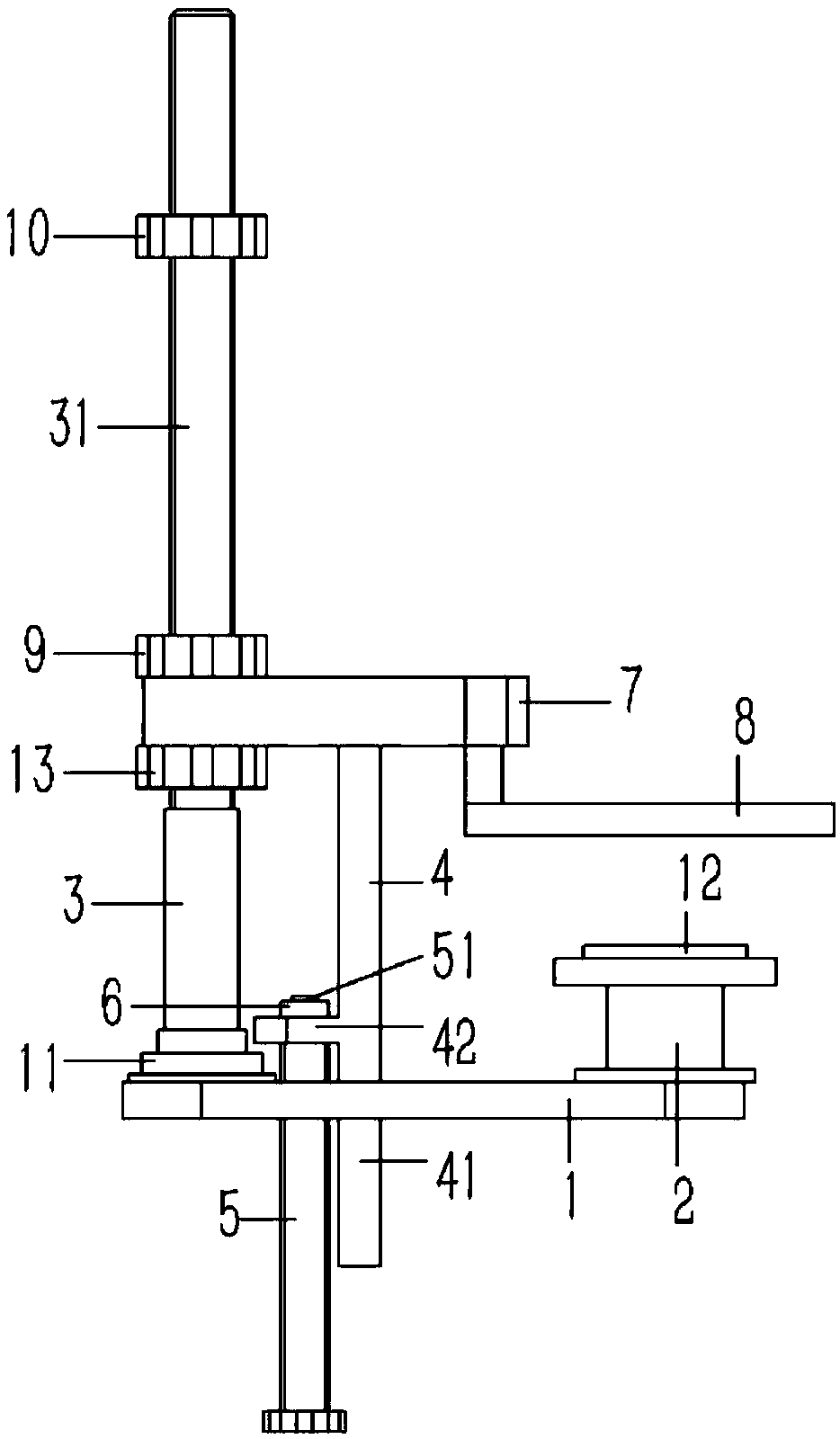

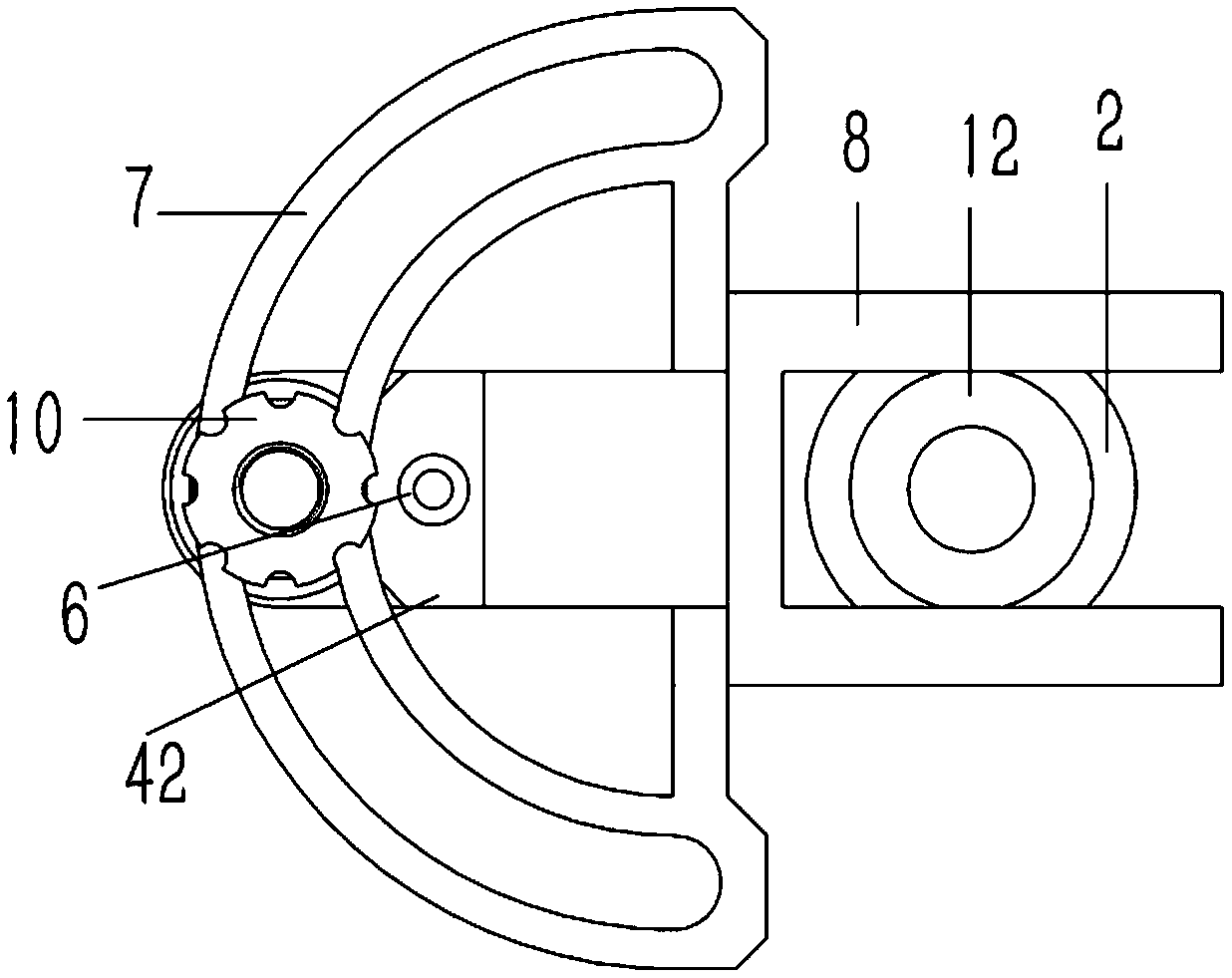

[0017] Example: see figure 1 , 2 , 3, a punching device applied to plastic shells, including a horizontal strip-shaped support plate 1, one end of the support plate 1 is fixed with an inverted T-shaped bracket 2, and the other end of the support plate 1 is hinged There is a column 3, and the upper end of the column 3 is formed with a vertical stud 31; the support plate 1 close to the column 3 is provided with a vertical plate 4, and the lower end of the vertical plate 4 is formed with a vertical insertion rod 41, and the insertion rod 41 is inserted On the support plate 1, a horizontal first support plate 42 is formed on the side wall of the vertical plate 4, and the support plate 1 on the lower side of the first support plate 42 is screwed with an adjusting bolt 5, and the upper end of the adjusting bolt 5 is formed with a pillar 51, the pillar 51 passes through the first support plate 42 to insert and fix the limit sleeve 6, the limit sleeve 6 abuts against the upper end su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap