Environment-friendly spackling compound and preparation method thereof

A putty paste, environment-friendly technology, applied in filling slurry and other directions, can solve the problems of improper material selection and ratio, low strength, easy powdering, unstable performance, etc., and achieves good environmental performance, not easy to delaminate, and stable quality performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of environment-friendly type putty paste is characterized in that concrete steps are as follows:

[0032] (1) Take konjac and potato as the main ingredients, wash and remove impurities and peel them respectively, weigh konjac and potato according to the mass ratio of 1:2~3, crush and mix them, add monochloroacetic acid, soda ash and water , react at 1 to 2 atmospheres and 100 to 130°C for 20 to 40 minutes, spray-dry or dry the resultant to 100 mesh, add hydroxyethyl cellulose, and mix well to prepare plant-modified polymer glue Powder, for standby; wherein 0.1-0.3 kg of monochloroacetic acid, 0.1-0.3 kg of soda ash, 180-220 kg of water and 3-5 kg of hydroxyethyl cellulose are added to every 100 kg of main ingredients;

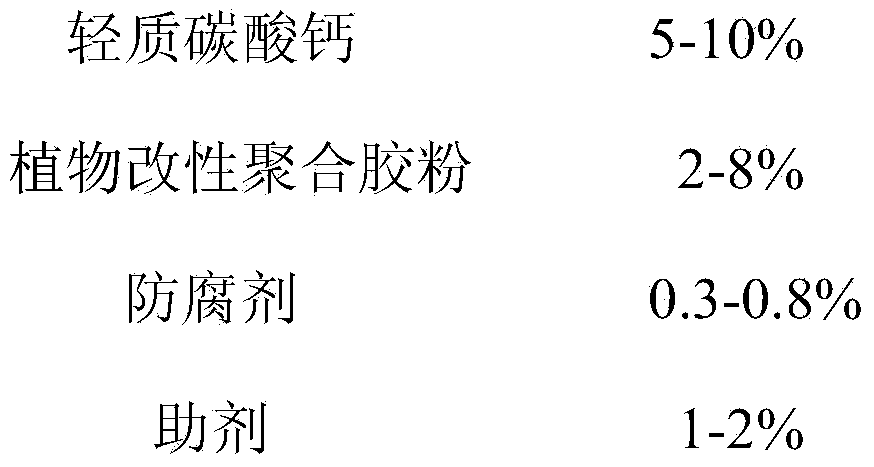

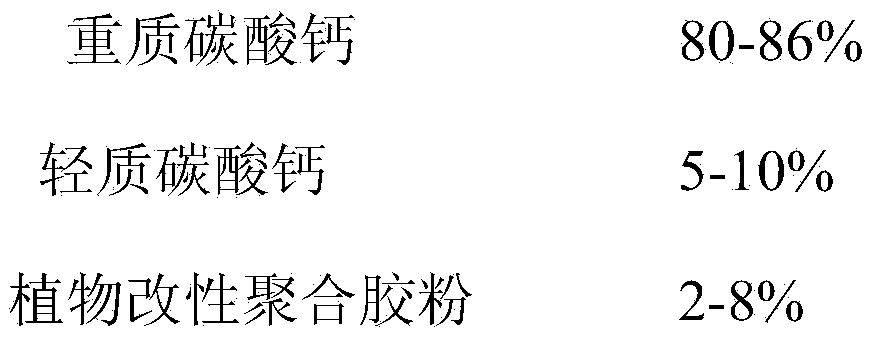

[0033] (2) Weigh 80% heavy calcium carbonate and 10% light calcium carbonate, then add 8% plant-modified polymer rubber powder, 0.8% sodium benzoate and 1.2% by mass %The auxiliary agent is mixed uniformly to form a solid com

Embodiment 2

[0036] A kind of preparation method of environment-friendly type putty paste is characterized in that concrete steps are as follows:

[0037] (1) Take konjac and potato as the main ingredients, wash and remove impurities and peel them respectively, weigh konjac and potato according to the mass ratio of 1:2~3, crush and mix them, add trichloroacetic acid, soda ash and water , react at 1 to 2 atmospheres and 100 to 130°C for 20 to 40 minutes, spray-dry or dry the resultant to 100 mesh, add hydroxyethyl cellulose, and mix well to prepare plant-modified polymer glue powder, for standby; wherein 0.1-0.3 kg of trichloroacetic acid, 0.1-0.3 kg of soda ash, 180-220 kg of water and 3-5 kg of hydroxyethyl cellulose are added to every 100 kg of main ingredients; The agent is monochloroacetic acid or trichloroacetic acid;

[0038] (2) Take by weight 86% heavy calcium carbonate and 5% light calcium carbonate, then add 7% plant-modified polymer rubber powder, 0.5% Casson and 1.5% by mass %

Embodiment 3

[0041] A kind of preparation method of environment-friendly type putty paste is characterized in that concrete steps are as follows:

[0042] (1) Take konjac and potato as the main ingredients, wash and remove impurities and peel them respectively, weigh konjac and potato according to the mass ratio of 1:2~3, crush and mix them, add monochloroacetic acid, soda ash and water , react at 1 to 2 atmospheres and 100 to 130°C for 20 to 40 minutes, spray-dry or dry the resultant to 100 mesh, add hydroxyethyl cellulose, and mix well to prepare plant-modified polymer glue Powder, for standby; wherein 0.1-0.3 kg of monochloroacetic acid, 0.1-0.3 kg of soda ash, 180-220 kg of water and 3-5 kg of hydroxyethyl cellulose are added to every 100 kg of main ingredients;

[0043] (2) Take by weighing 84.5% heavy calcium carbonate and 8% light calcium carbonate, then add 5% plant-modified polymer rubber powder, 0.5% sodium benzoate and 0.5% by mass 2% additives are mixed evenly to form a solid c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap