Polyvinyl acetate polymerization method

A technology of polyvinyl acetate and polymerization method, which is applied in the field of polyvinyl acetate polymerization, can solve problems such as sales barriers, color difference between solid and solution, heavy odor, etc., and achieve the effect of good quality and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now to process The PVAc is example, non-limiting embodiment is described as follows:

[0019] 1. Ingredients

[0020] Take VAC 1000L (approximately 930kg) with a purity of 99.3%, add 200L of methanol and put it into a polymerization kettle equipped with a stirrer and a reflux condenser.

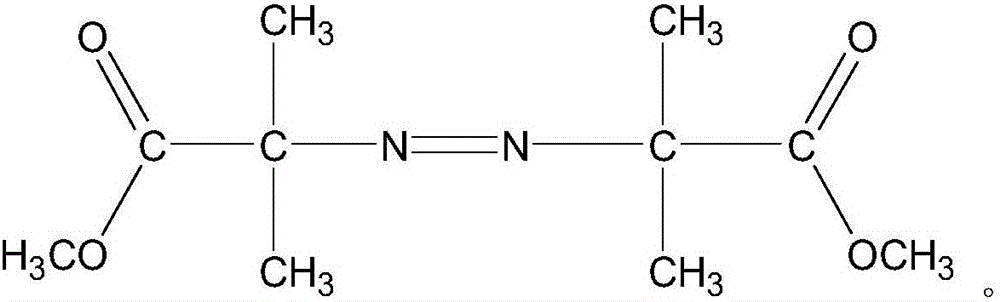

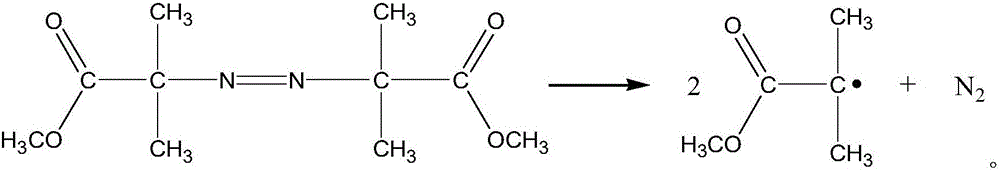

[0021] Take 0.47kg of initiator AIBME (0.05% of VAc mass) to prepare a methanol solution with a concentration of 0.8-1.5%.

[0022] 2. Polymerization

[0023] When the monomer is preheated to 59°C, add the methanol solution of initiator and chain transfer agent, polymerize at 65°C for 2 hours at a stirring speed of 5-9 rpm, then reduce the speed to 4-7 rpm, continue Polymerized for 2 hours.

[0024] 3. Separation

[0025] After the polymerization reaction is finished, the reaction liquid is transferred to a still, and methanol vapor is blown into from the bottom of the still to collect the distilled VAc, methanol and water azeotrope. Inside the kettle is PVAc methanol solution.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap