Silicon monoxide composite material, preparation method thereof and lithium ion battery

A lithium-ion battery and silicon oxide technology, applied in the field of materials, can solve the problems of poor electrical conductivity of silicon oxide and low first coulomb efficiency, and achieve the effects of excellent electrical conductivity, improved first coulomb efficiency, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the silicon oxide composite material of the embodiment of the present invention comprises the following steps:

[0032] The first stage: Introduce protective gas into the vapor deposition furnace, and preheat the silicon oxide raw material at the same time, so that part of the silicon oxide raw material undergoes disproportionation reaction;

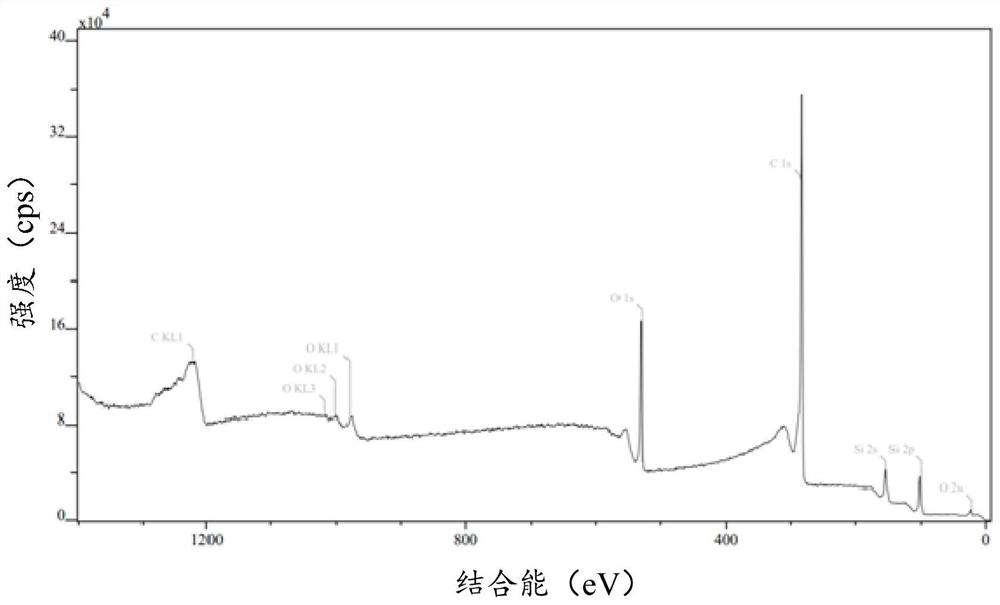

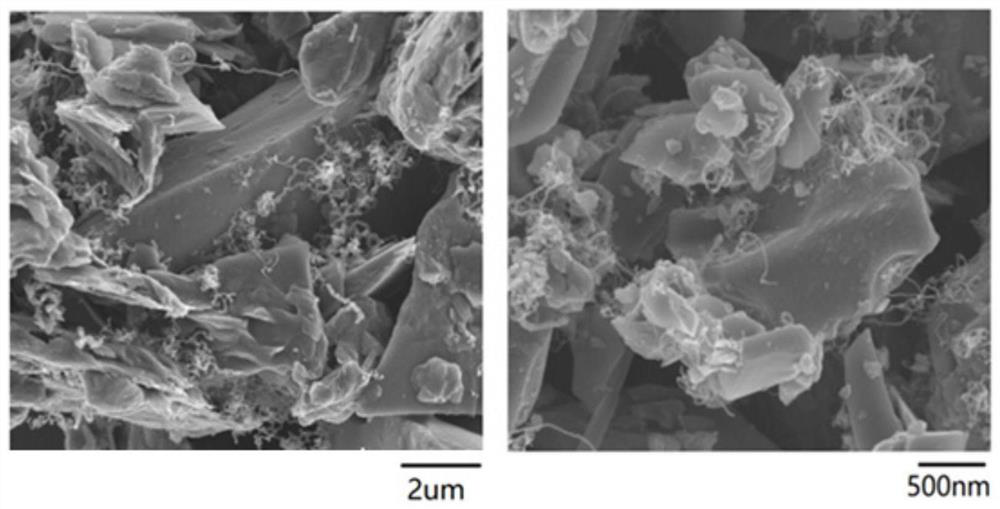

[0033] The second stage: continue to feed protective gas and carbon source gas, and perform chemical vapor deposition on the preheated silicon oxide raw material to form carbon nanotubes on the surface of silicon oxide;

[0034] The third stage: After a predetermined time, stop feeding the carbon source gas, and stop feeding the protective gas after the vapor deposition furnace cools down to room temperature, to prepare the silicon oxide composite material.

[0035] Among them, in the first stage, the silicon oxide raw material with a diameter of 100nm to 100 μm is put into the vapor deposition furnace. Beca

Embodiment 1

[0049] Take 1 kg of silicon oxide raw material with a diameter of 100nm ~ 100μm and put it into a vapor deposition furnace, pass nitrogen gas at a flow rate of 2L / min to remove the air inside, then start heating up to 600°C at a heating rate of 2°C / min, control the gas phase The rotational speed of the deposition furnace was 1 rpm; the temperature was maintained at 600°C for 1 h; nitrogen was continuously fed at a flow rate of 2 L / min, and methane was fed at a flow rate of 1 L / min at the same time, and the rotational speed of the vapor deposition furnace was controlled to be 2 rpm.

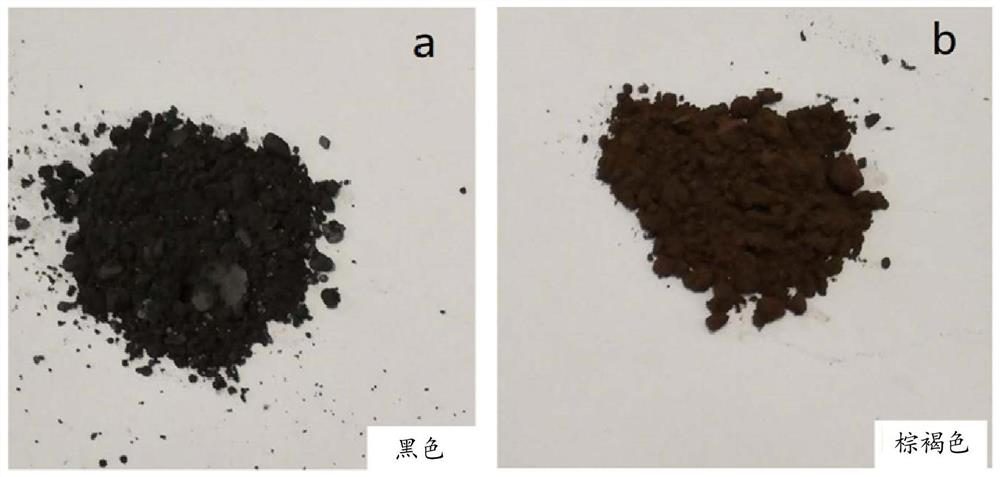

[0050] After 8 hours, the feeding of methane was stopped, and after the vapor deposition furnace was cooled to room temperature, the feeding of nitrogen gas was stopped to obtain a silicon oxide composite material.

Embodiment 2

[0052] Take 1 kg of silicon oxide raw material with a diameter of 100nm ~ 100μm and put it into a vapor deposition furnace. After passing nitrogen gas at a flow rate of 1L / min to remove the air inside, start heating up to 800°C at a heating rate of 5°C / min. Control the gas phase The rotation speed of the deposition furnace is 2rpm; keep the temperature at 800°C for 0.5h; then raise the temperature to 1000°C at a rate of 10°C / min; The flow of min is fed into methane, and the speed of the vapor deposition furnace is controlled to be 0.5rpm.

[0053] After 3 hours, the feeding of methane was stopped, and after the vapor deposition furnace was cooled to room temperature, the feeding of nitrogen gas was stopped to obtain a silicon oxide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap