Rechargeable lithium battery

a rechargeable lithium battery and lithium-ion battery technology, applied in the field of rechargeable lithium batteries, can solve the problems of sharp cycle-life deterioration of silicon-based active materials, and insufficient realization of the high-capacity required for rechargeable lithium batteries, and achieve the effect of improving cycle-life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

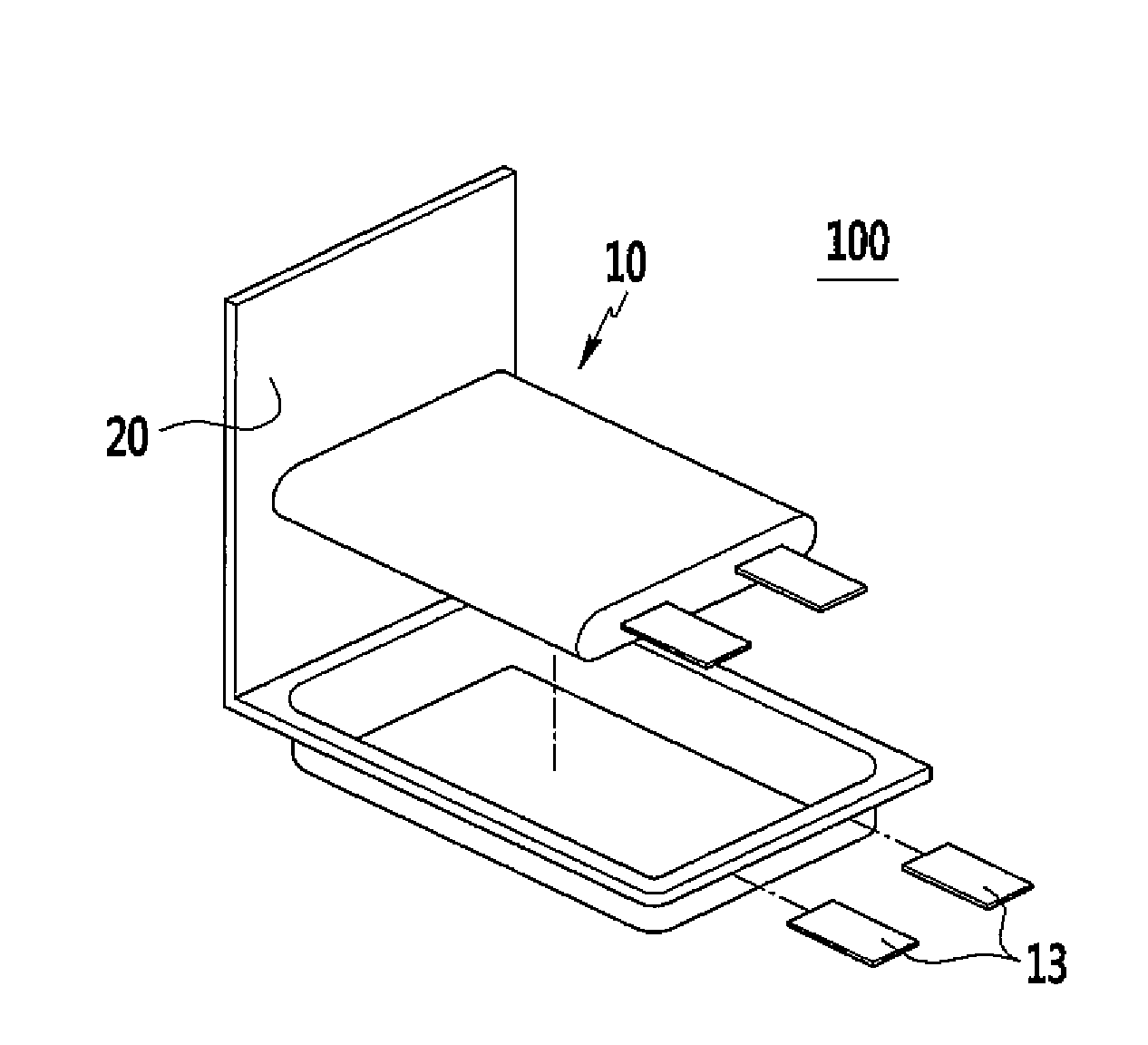

Image

Examples

example 1

Manufacture of A Positive Electrode

[0091]A positive active material layer composition was prepared by mixing polyvinylidene fluoride (PVdF), carbon black, and a mixture of 80 wt % of LiCoO2 and 20 wt % of LiNi0.5Co0.2Mn0.3O2, in a weight ratio of 4:4:92 and dispersing the obtained mixture in N-methyl-2-pyrrolidone. The positive active material layer composition was coated on a 20 μm-thick aluminum foil, dried, and compressed to manufacture a positive electrode.

Manufacture of a Negative Electrode

[0092]A negative active material layer composition was prepared by mixing polyvinylidene fluoride (PVdF) and a mixture of 90 wt % of graphite and 10 wt % of Si—Fe alloy (a mole ratio of Si:Fe=4:6) (CV4, 3M) in a weight ratio of 8:92 and dispersing the resulting mixture in N-methyl-2-pyrrolidone. The negative active material layer composition was coated on a 15 μm-thick copper foil, dried, and compressed to manufacture a negative electrode.

Preparation of an Electrolyte Solution

[0093]An electrolyt

example 2

[0095]A rechargeable lithium battery cell was manufactured according to the same method as Example 1 except for preparing the electrolyte solution by adding an additional 3 parts by weight of LiB(C2O4)F2 based on 100 parts by weight of the mixed solvent.

example 3

[0096]A rechargeable lithium battery cell was manufactured according to the same method as Example 1 except for using a separator manufactured as follows.

[0097]The separator was manufactured by coating a coating material prepared by mixing 2 parts by weight of Al2O3 (having an average particle diameter of 200 μm) and 5 parts by weight of polyvinylidene fluoride (PVdF) based on 100 parts by weight of a substrate on one surface of the polyethylene substrate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap