High-temperature resistant anti-corrosion clay special for acid pressure oxidative leaching high-pressure autoclave and preparation method thereof

A technology of oxygen pressure acid leaching and anti-corrosion cement, which is applied in the field of high-temperature anti-corrosion cement for oxygen pressure acid leaching autoclave and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preparation method of the high-temperature anti-corrosion mortar special for oxygen pressure acid leaching autoclave is characterized in that the specific process is as follows:

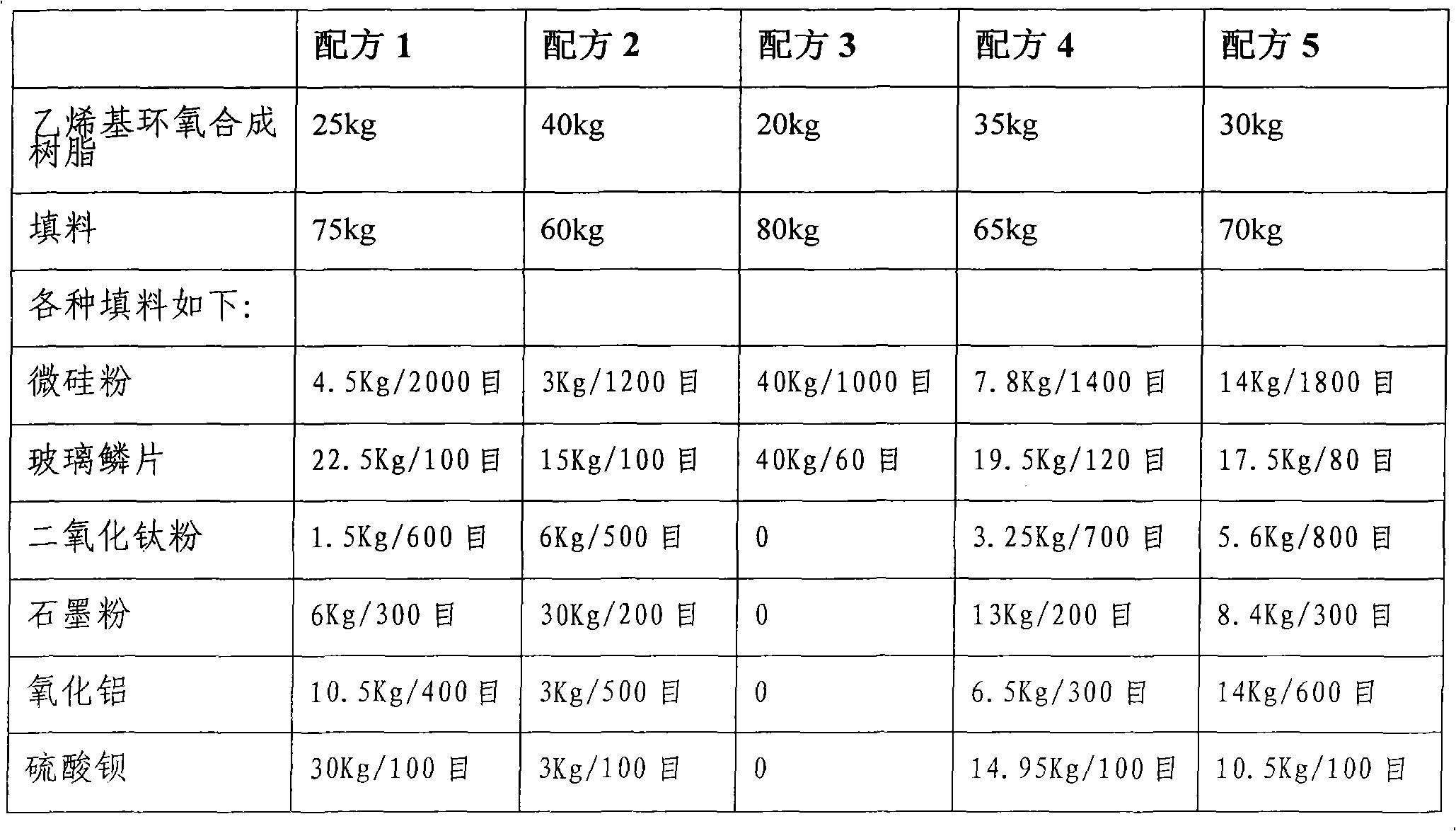

[0015] (1) Prepare materials according to Table 1, and the raw materials are all qualified products purchased on the market,

[0016] (2) Put the vinyl epoxy synthetic resin into the reaction kettle and heat it to 120°C,

[0017] (3) Vacuum stirring and kneading, synthetic resin and powdery or flaky fillers are mixed in a two-way stirring kneader under vacuum, the vacuum degree is -0.03MPa, fully stirred, the stirring time is 30-40min, and the cement after kneading The ingredients are mixed evenly until there is no dry powder, lumps, and no air bubbles. It is a high-temperature anti-corrosion mastic for oxygen pressure acid leaching autoclave.

[0018] Table 1

[0019]

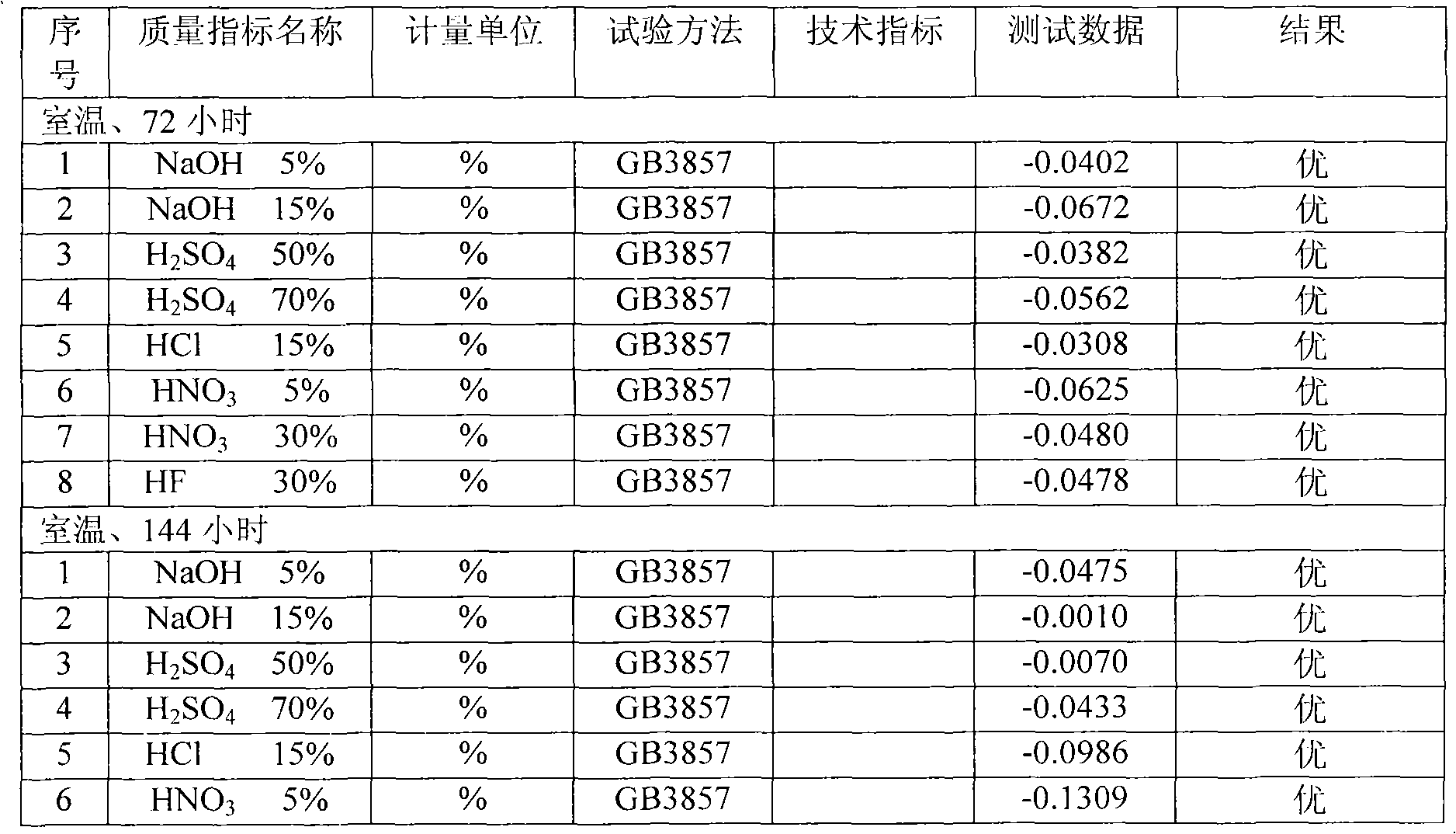

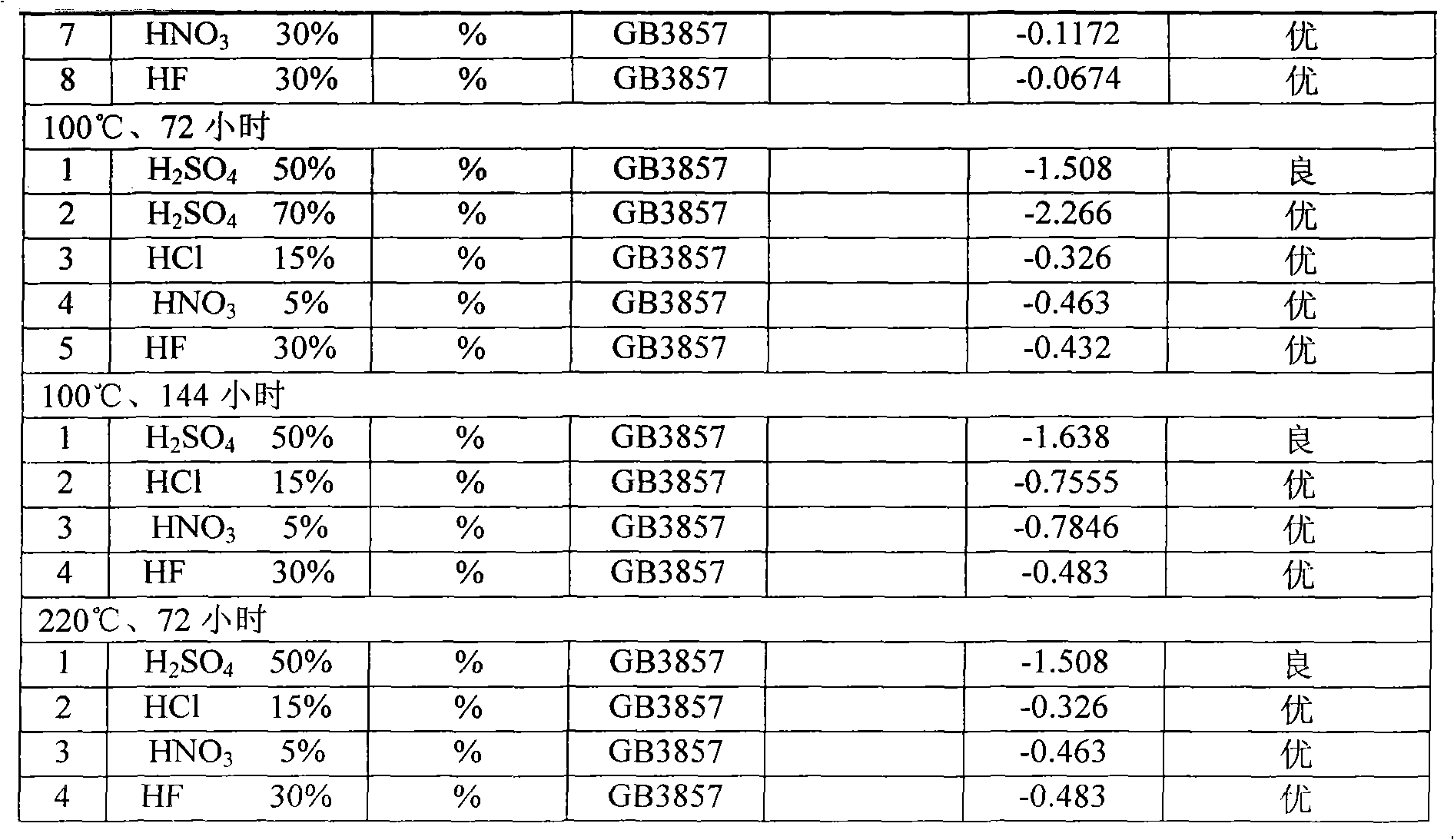

[0020] (4) inspection

[0021] Quality Supervision and Inspection Center for Non-metallic Materials and Equipment, M

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap