Method for manufacturing high-activity mineral blending material and application thereof

A technology of mineral admixture and high activity, which is applied in the field of preparation of high activity mineral admixture, can solve the problems of increased water demand of concrete, single source of silica fume, increase of concrete shrinkage, etc., and achieves economic benefits and environmental protection. Excellent benefits, broad promotion and application prospects, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

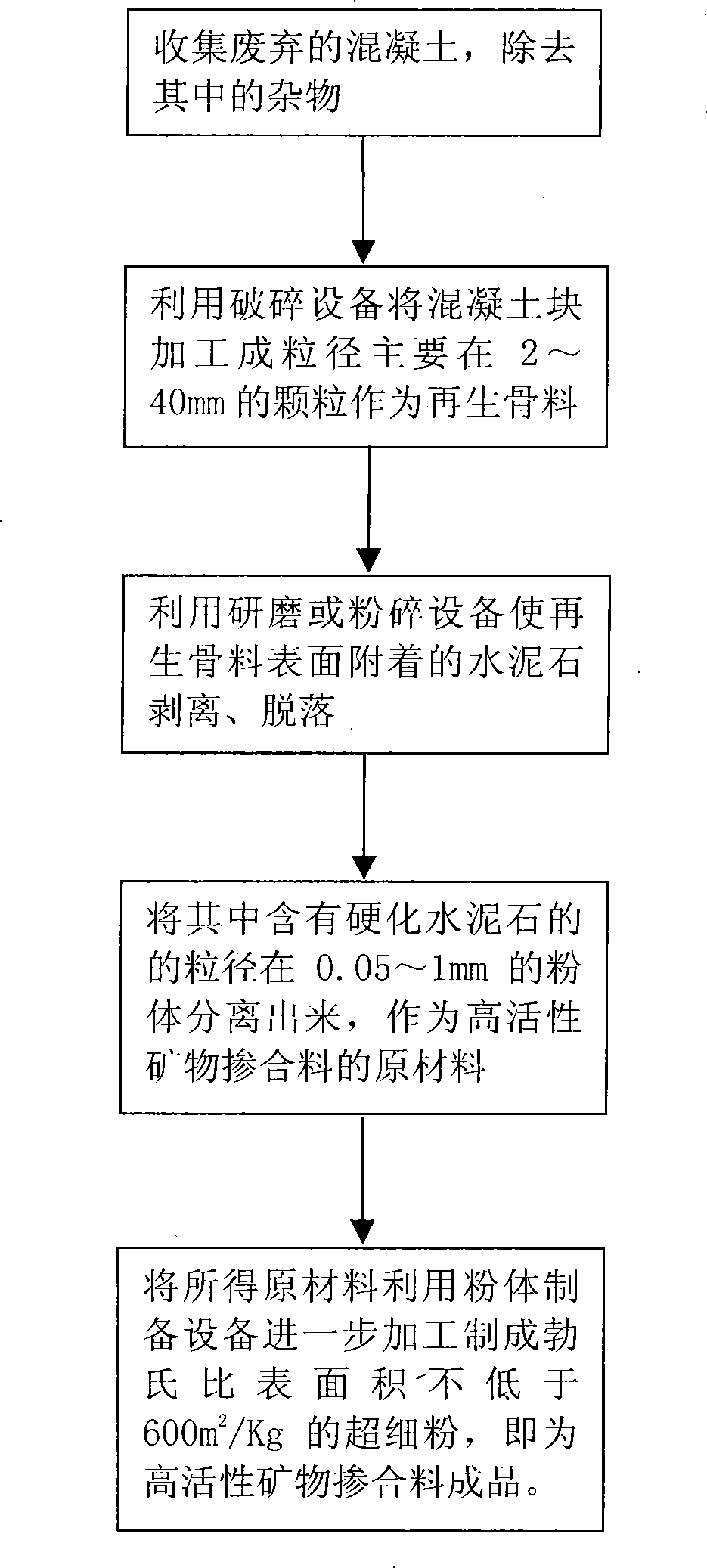

[0023] like figure 1 The preparation method of shown highly active mineral admixture of the present invention comprises following specific steps:

[0024] (1) Collect waste concrete, remove wood, plastic and other sundries therein, and use a hammer crusher to process concrete blocks into particles whose particle size is mainly distributed in 2-30mm as recycled aggregate;

[0025] (2) Utilize the friction between the grinder and the recycled aggregate during the high-speed rotation of the grinder to peel off and fall off the cement stone attached to the surface of the recycled aggregate, and then make the powder containing hardened cement stone with a particle size of 0.08-0.8mm Separation through grading and screening equipment, as raw materials for highly active mineral admixtures;

[0026] (3) Through the jet mill, the collected powder containing hardened cement stone is made into a Blaine specific surface area of 600-650m 2 / Kg ultrafine powder is the finished product.

Embodiment 2

[0029] like figure 1 The preparation method of shown highly active mineral admixture of the present invention comprises following specific steps:

[0030] (1) Collect waste concrete, remove impurities such as bricks, tiles, metals, etc., and use a jaw crusher to process concrete blocks into particles whose particle size is mainly distributed in the range of 2 to 40 mm as recycled aggregates;

[0031] (2) Using a particle shaping machine, through the high-speed self-impact (linear speed greater than 60m / s) and friction between the recycled aggregates, the cement stone attached to the surface of the recycled aggregate is peeled off and falls off, and the particle size of the hardened cement stone is contained. The powder with a thickness of 0.05-1mm is collected by the dust collector in the particle shaping machine and used as a raw material for highly active mineral admixtures;

[0032] (3) Process the obtained powder containing hardened cement stone through a jet mill to make

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap