Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Manufacturing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing efficiency is the level of performance within your company, and it's something that can always be improved upon. 1. Know your product, and make sure everybody in your company knows the product. Manufacturing efficiency starts with well-trained individuals throughout the entire company.

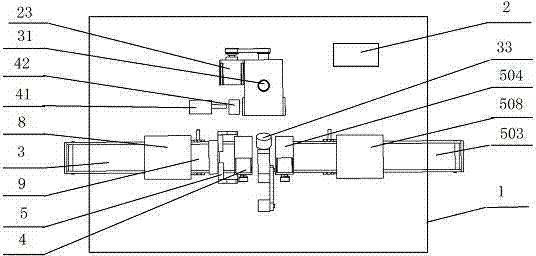

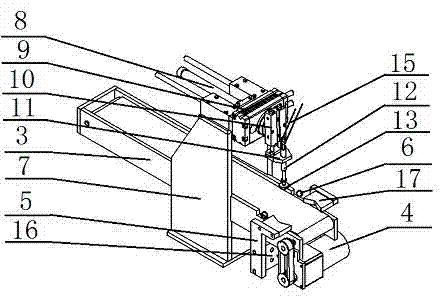

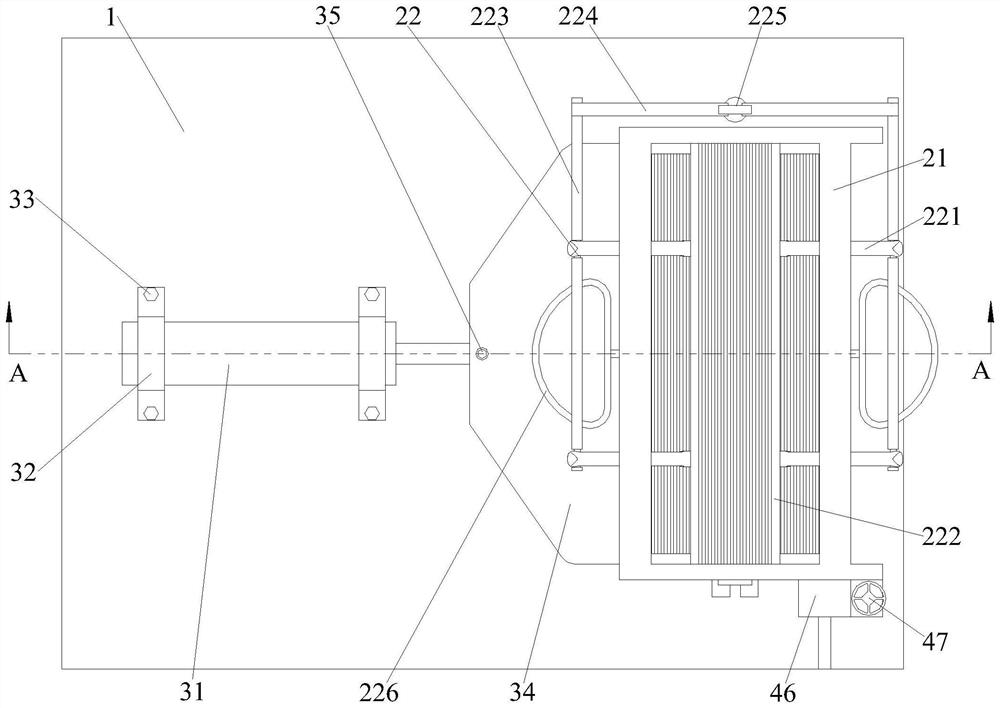

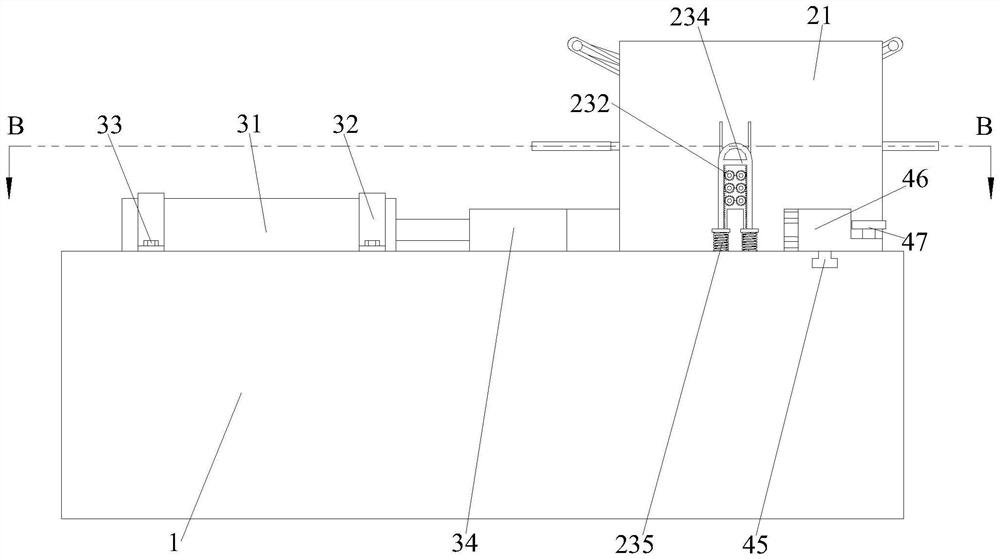

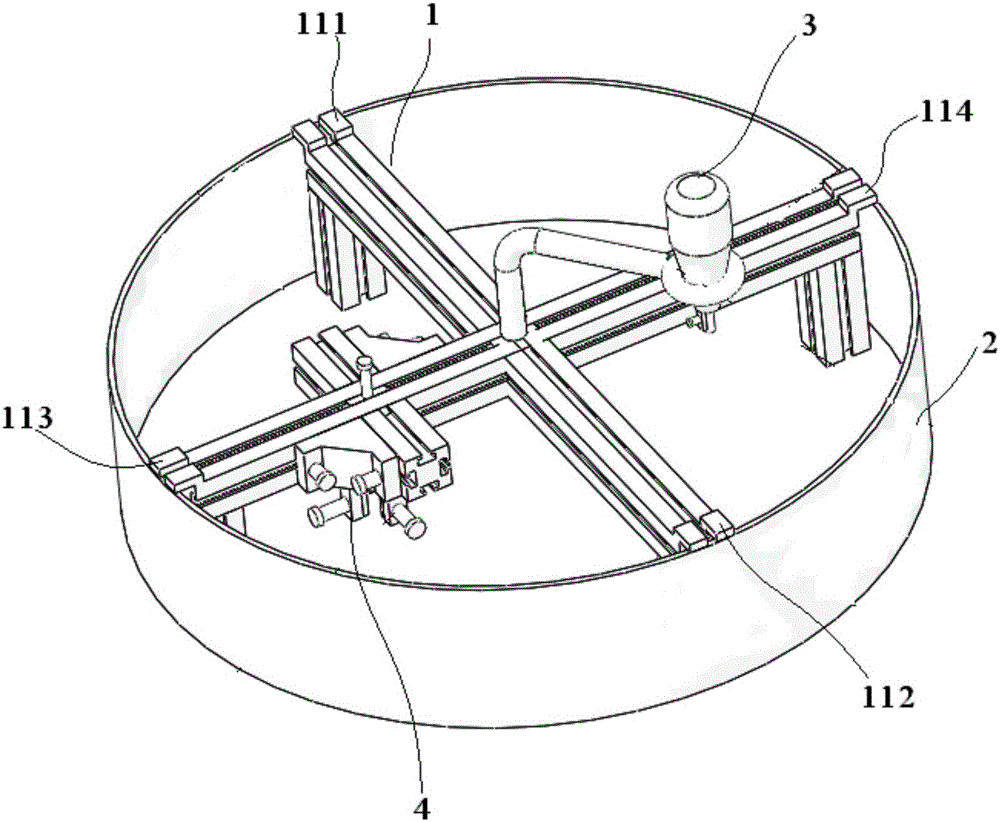

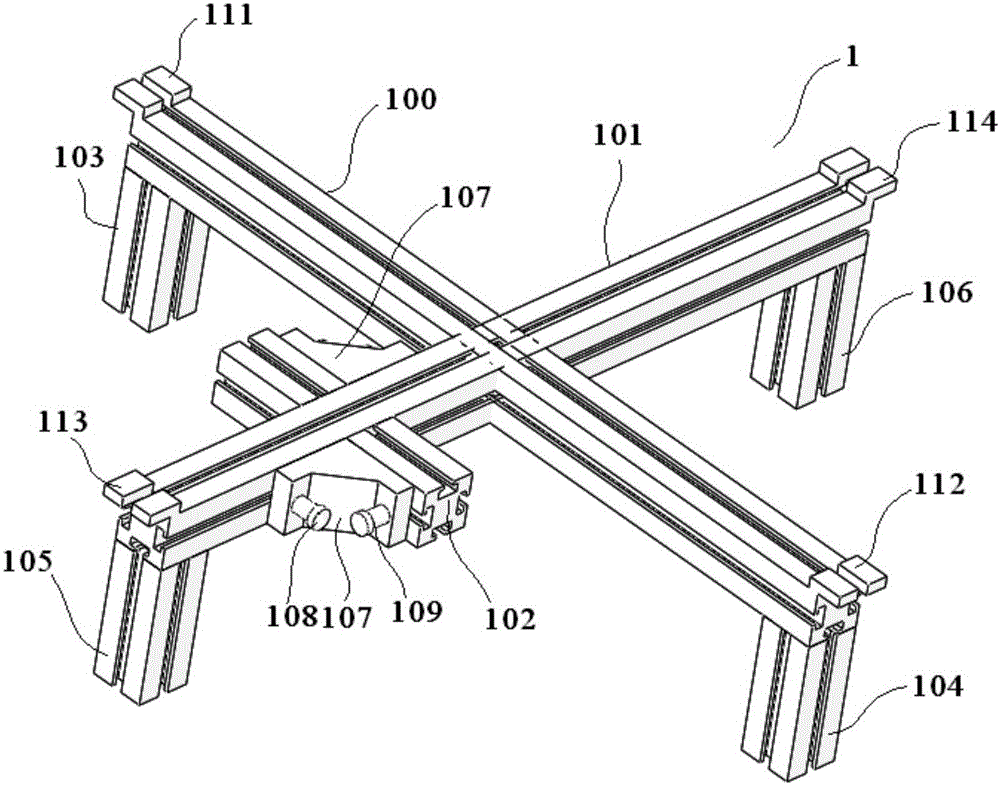

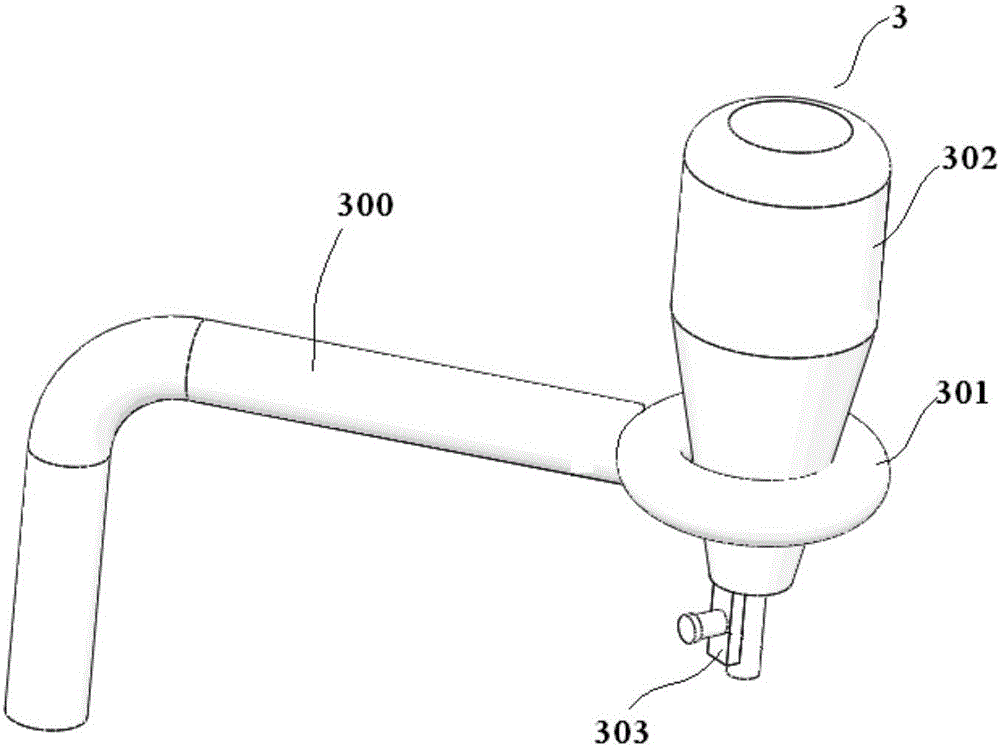

Full-automatic resin lens casting machine

Owner:LINHAI JINZHENG MACHINERY

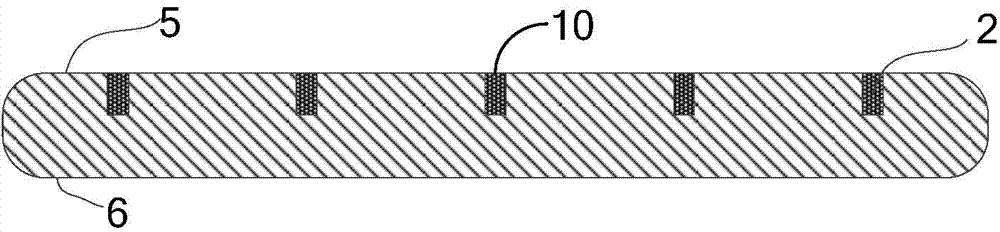

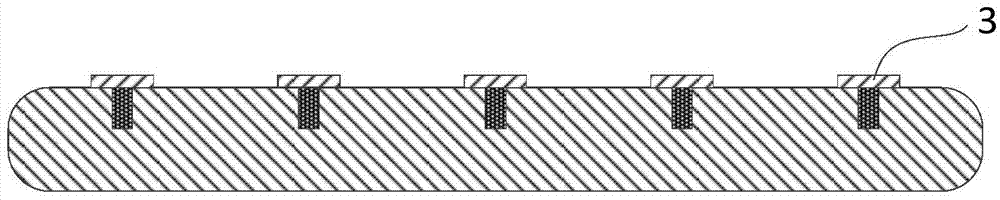

Packaging structure and method based on ultra-thin glass

ActiveCN103943605AAvoid efficiencyLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringThin glass

Owner:NAT CENT FOR ADVANCED PACKAGING

Automatic box-dropping device for shaped and boxed beancurd processing device

InactiveCN102715445AAutomatic placementIncrease productivityCheese manufacturePackagingEngineeringMicrocomputer control

Owner:SUZHOU JINJI FOODS

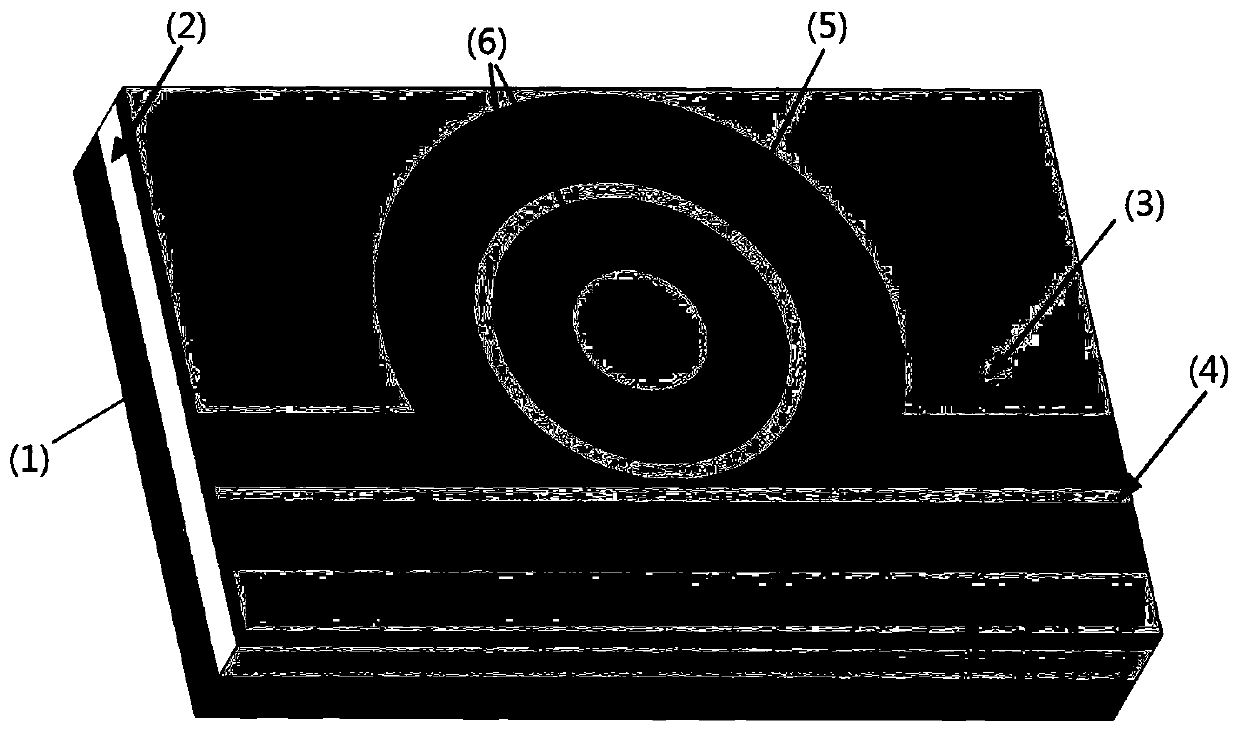

Magnetothermal effect-based magnetic field measurement method, magnetic field sensor and preparation method

ActiveCN110456288AOptimal size designChange sensitivityMagnitude/direction of magnetic fieldsTerra firmaResonance

Owner:CHONGQING UNIV

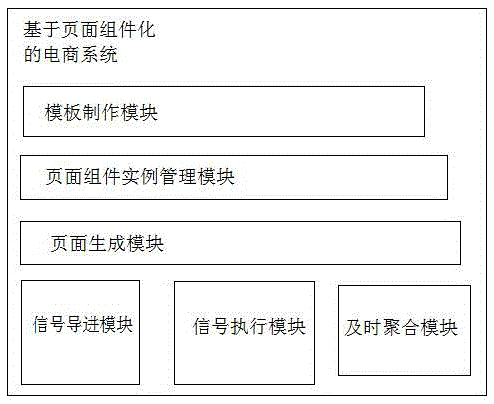

E-commerce system and method based on page modularization

Owner:NANJING XINWANG INTERNET INFORMATION TECH CO LTD

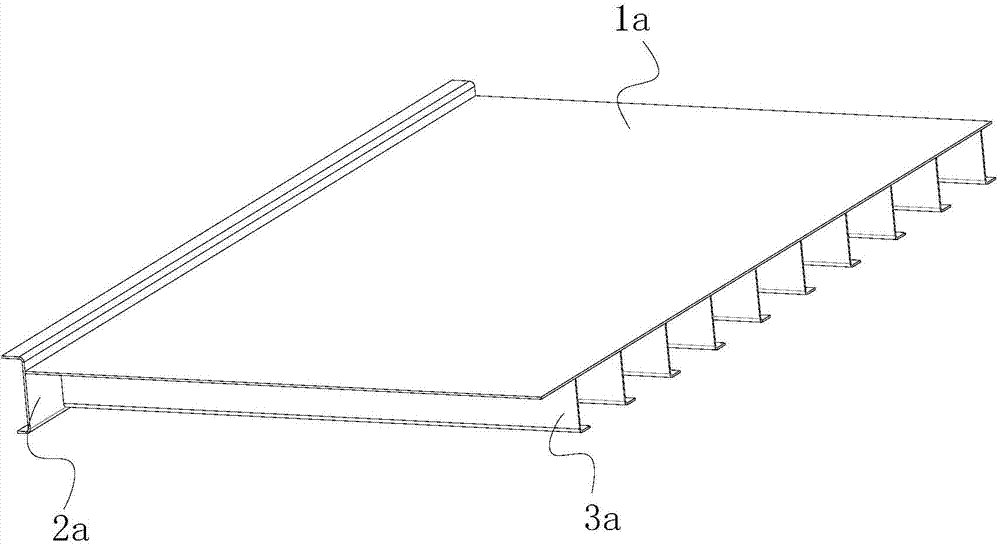

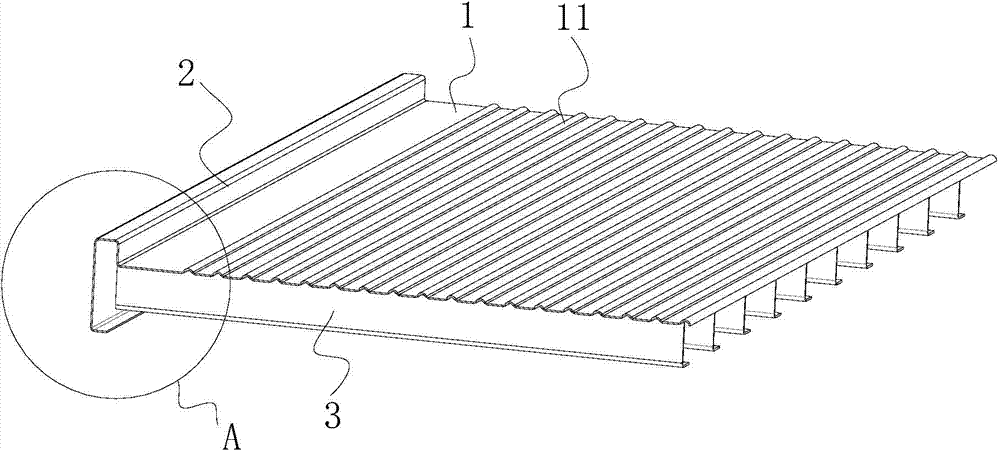

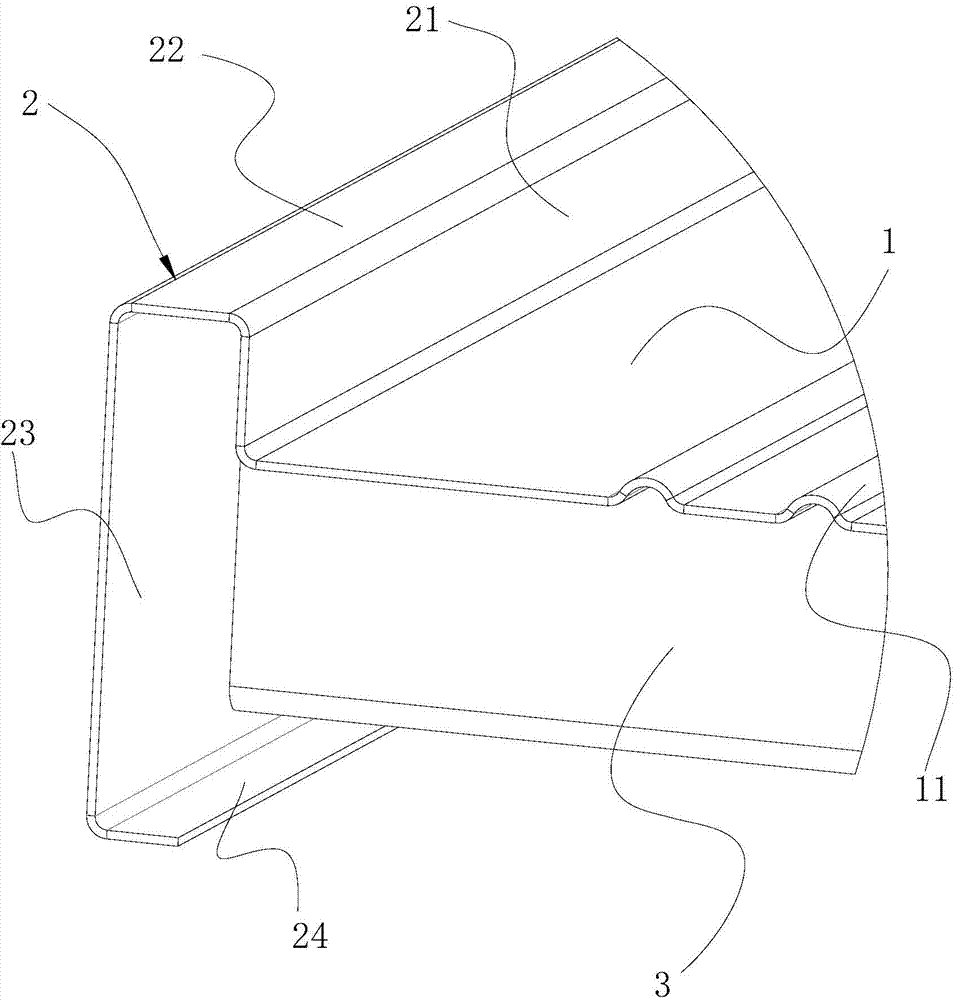

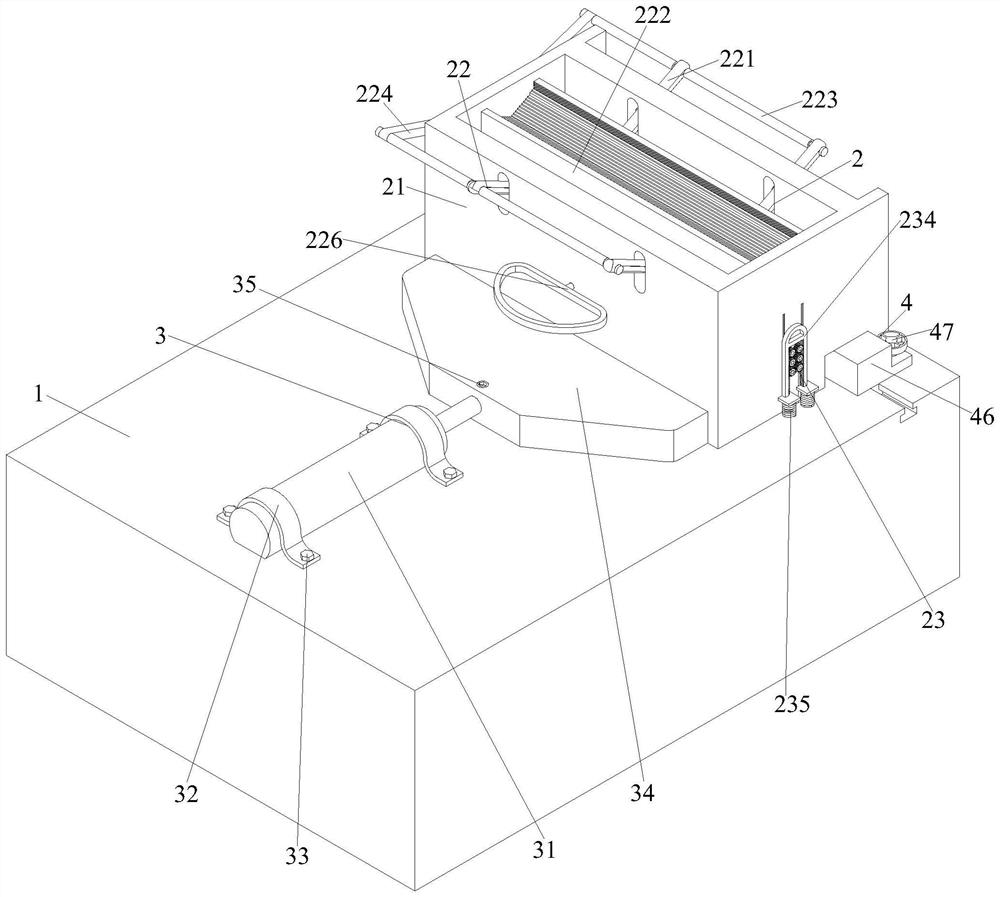

Container and steel floor chassis thereof

ActiveCN104743287AImprove manufacturing efficiencyReduce labor costsLarge containersManufacturing efficiencyUltimate tensile strength

The invention discloses a container and a steel floor chassis thereof. The steel floor chassis comprises a steel floor, bottom side beams positioned at transverse two sides of the steel floor, and multiple bottom cross beams longitudinally arranged below the steel floor and fixedly connected with the steel floor, wherein the two ends of the bottom cross beams are fixedly connected with the two bottom side beams; and the bottom side beams are bent from the side edges of the steel floor, and are integrally molded with the steel floor. The steel floor chassis improves the manufacturing efficiency, reduces the cost, and improves the whole strength.

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS +2

Machining method for steel members

ActiveCN106695253AImprove production efficiencyReduce processing stepsStrutsPillarsEconomic benefitsMachining

The invention belongs to the technical field of building materials and provides a machining method for steel members. According to the method, firstly, the number of target steel members needing to be machined and required parameters are determined; then, the shapes and sizes of combined steel members are determined, and corresponding bed-jigs are prepared; main part assembling of the combined steel members and part assembling and welding are completed on the bed-jigs; and finally, according to the number of the target steel members and the required parameters, the combined steel members are cut, and then a preset number of target steel members with preset length are obtained. According to the machining method for the steel members, after a steel raw material is assembled and welded into one combined steel member, cutting is carried out, and at least two steel members with the same cross section form and the same length or different lengths are obtained. Compared with an existing machining method for independent one-by-one assembling and welding of the single steel raw material, the machining method has the beneficial effects that the machining procedures are reduced, the manufacturing efficiency of the steel members is greatly improved, the cost is reduced easily, and the considerable economic benefits are created.

Owner:CHINA CONSTR STEEL STRUCTURE GUANGDONG CO LTD +1

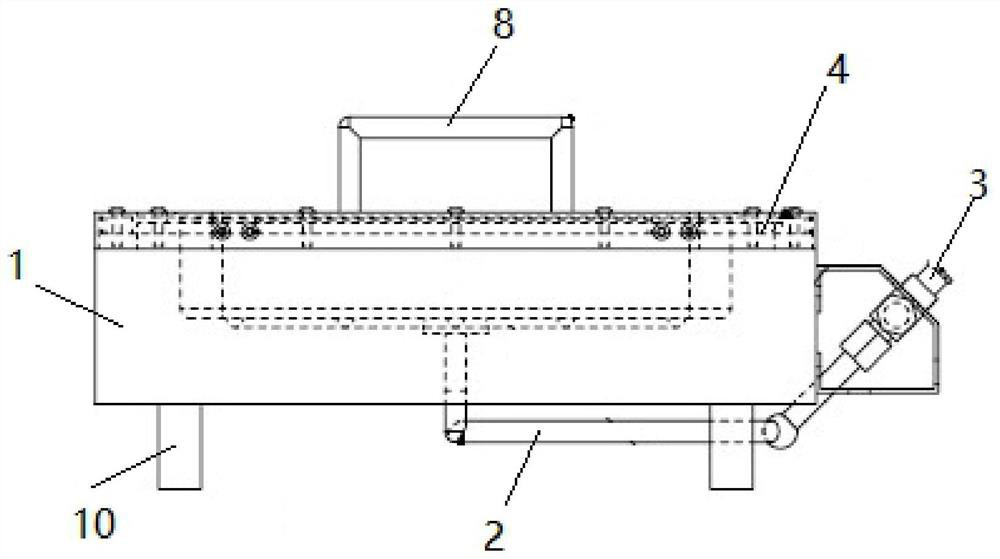

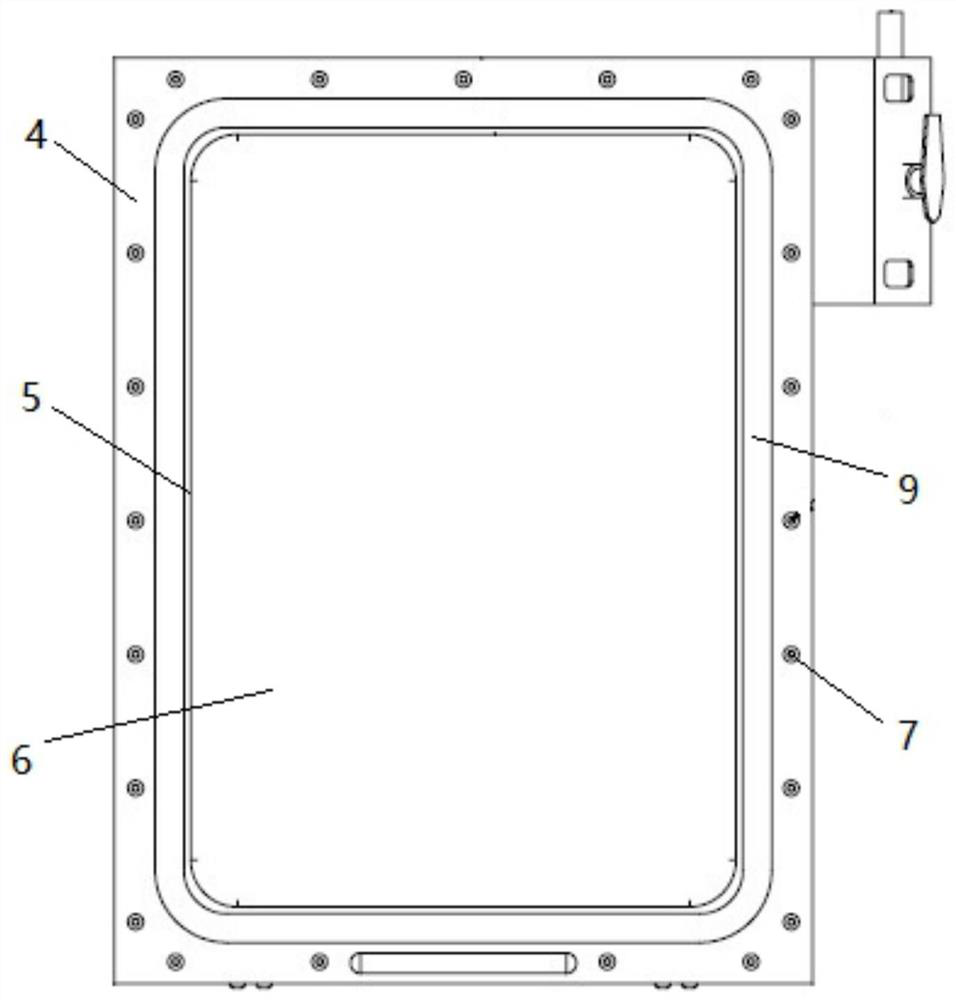

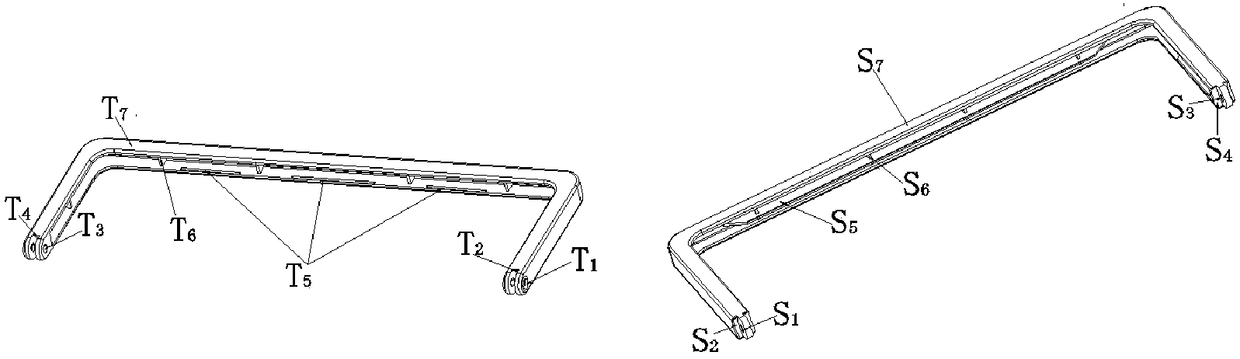

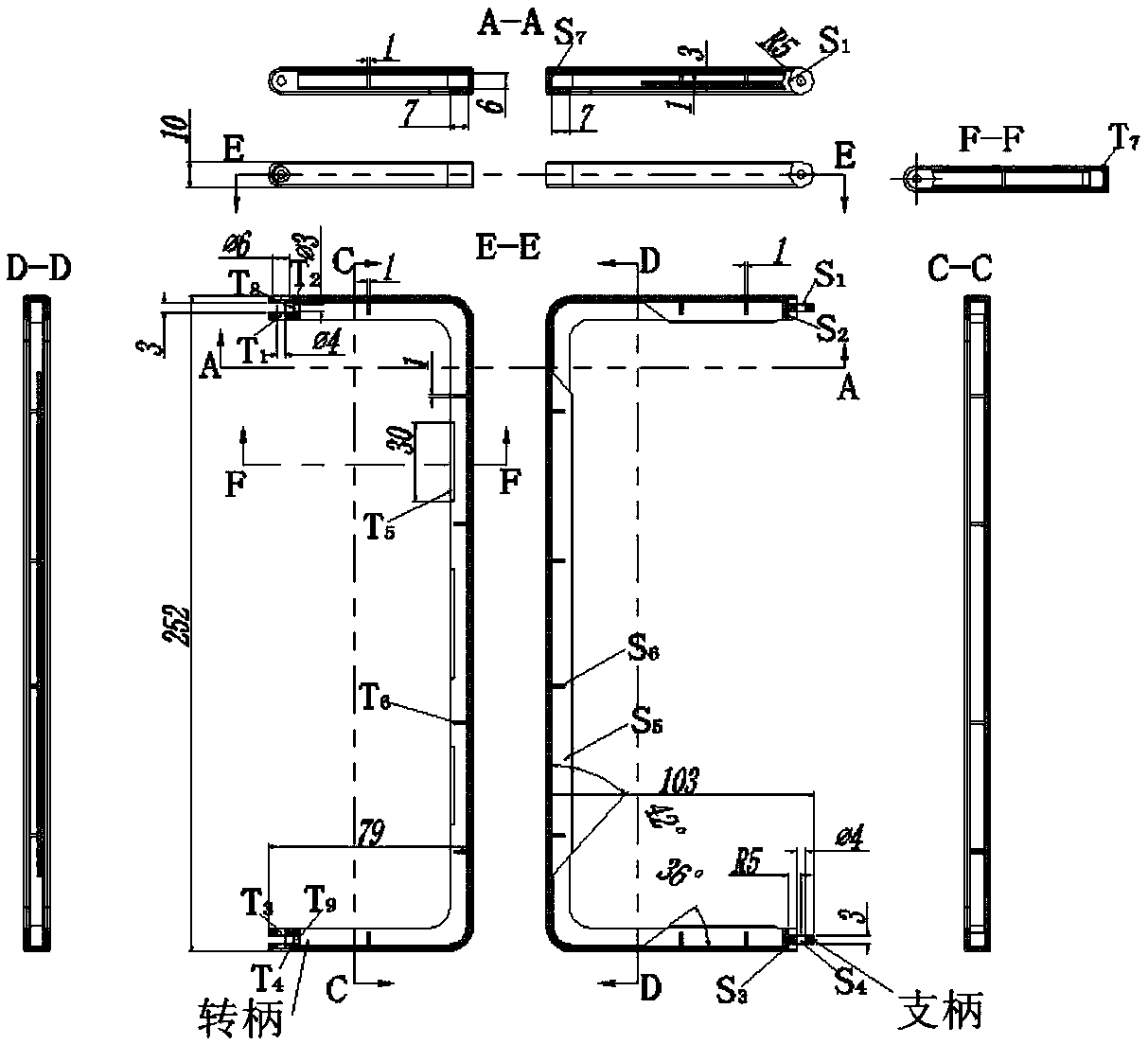

Carton manufacturing equipment

InactiveCN109968734AImprove production efficiencyImprove stabilityPaper-makingBox making operationsCartonEnergy consumption

The invention discloses carton manufacturing equipment. The equipment comprises a packaging carton edge sealing machine body, wherein a conveying cavity is formed in the machine body in a left and right penetrating mode, a conveying belt groove with an upward opening is formed in the lower side of the conveying cavity in a communicating mode, conveying rotating shafts are arranged in the conveyingbelt groove in a left-right symmetric mode, the front ends and the rear ends of the conveying rotating shafts are rotationally connected with the front end wall and the rear end wall of the conveyingbelt groove respectively, conveying wheels are fixedly arranged on the conveying rotating shafts, and the conveying wheels are in power connection through a conveying belt. The equipment is simple instructure and convenient to operate, the edge sealing device is used for binding to-be-sealed edges of a packaging carton, in the binding process, a reversing device controls rotation direction of the conveying belt, so that the packaging carton is moved to the right side of the edge sealing device, after the edge sealing device descends to a lifting cavity, the carton retracts to the edge sealing device to be bound, the equipment is used in the later package forming process, and full-automatic packaging and forming of the equipment are achieved. Compared with traditional manual edge sealing,the equipment has the advantages that the time is saved, the carton manufacturing efficiency is high, the edge sealing integrity is good, and the energy consumption is low.

Owner:HANGZHOU ZHIAI PACKAGING PROD CO LTD

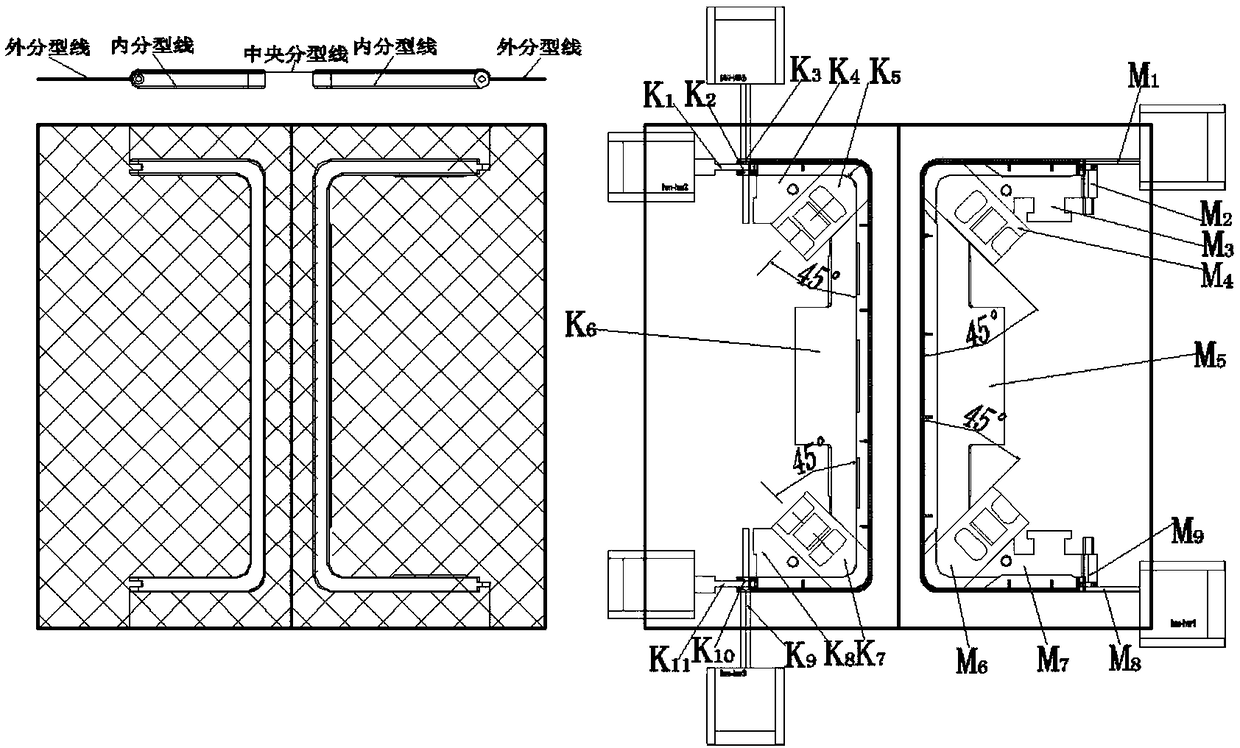

Structure improved glass mould

The invention relates to a structure improved glass mould. The glass mould includes a pair of bottle half-dies, each bottle half-die has a bottle half-die cavity and a bottle bottom die cooperating cavity under the bottle half-die cavity, first axial exhaust holes are arranged in the semi-arc direction of the bottle half-die, and extend downward from the top of the bottle half-die to an air outletring groove, which is arranged on the outer wall of the bottle half-die, second axial exhaust holes are arranged in the semi-arc direction of the bottle half-die and on the inner sides of the first axial exhaust holes, the second axial exhaust holes correspond to the neck and shoulder area of the bottle half-die, and the bottle half-die cavity and the second axial exhaust holes are communicated by radial exhaust holes. The glass mould is characterized in that: an edge accelerated cooling mechanism is formed around the semi-arc direction of the bottle half-die corresponding to a position abovethe air outlet ring groove on the outer wall of the bottle half-die, switches off the lower ends of the first axial exhaust holes, and enables communication of the lower ends of the first axial exhaust holes with itself. The structure improved glass mould can improve the manufacturing efficiency of glass containers with rectangular cross-sections and guarantee the quality of glass containers.

Owner:CHANGSHU JIANHUA MOLD TECH

Honeycomb plate metal strip edge sealing extrusion forming device

Owner:艾博特镭射科技徐州有限公司

Metallographical test piece polishing clamp

ActiveCN105710780AFlexible useAdjust the clamping situation in timePreparing sample for investigationGrinding work supportsStress conditionsTest sample

Owner:FENGYANG L S NET FORMING CO LTD

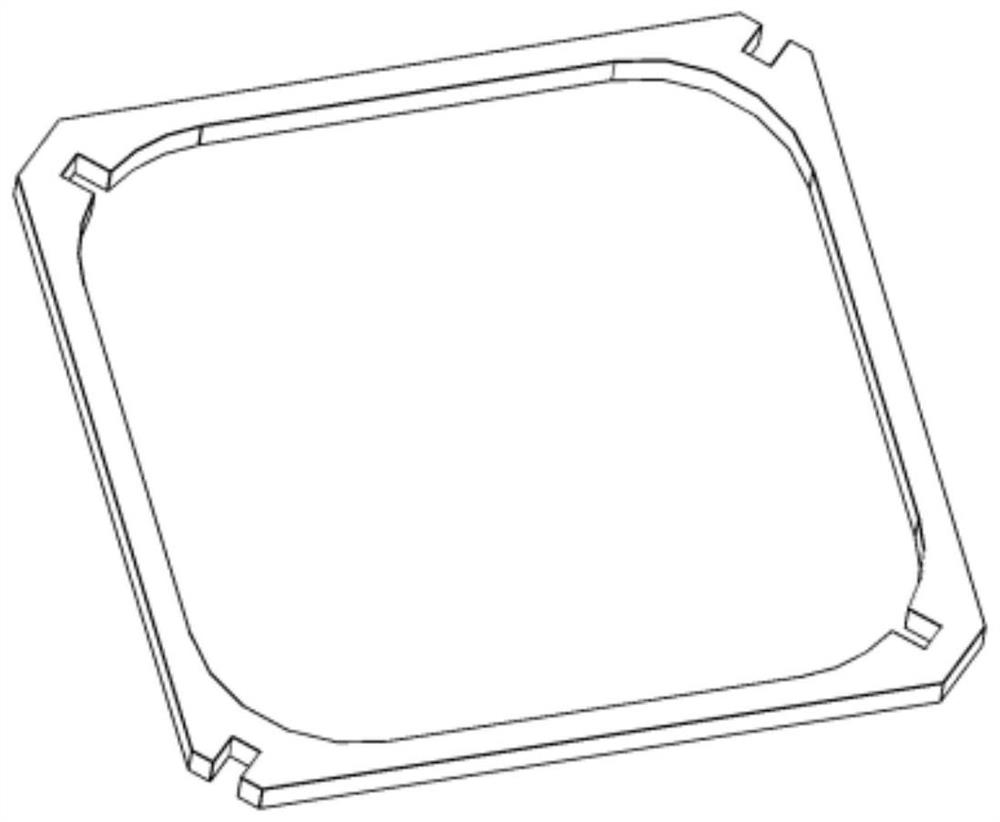

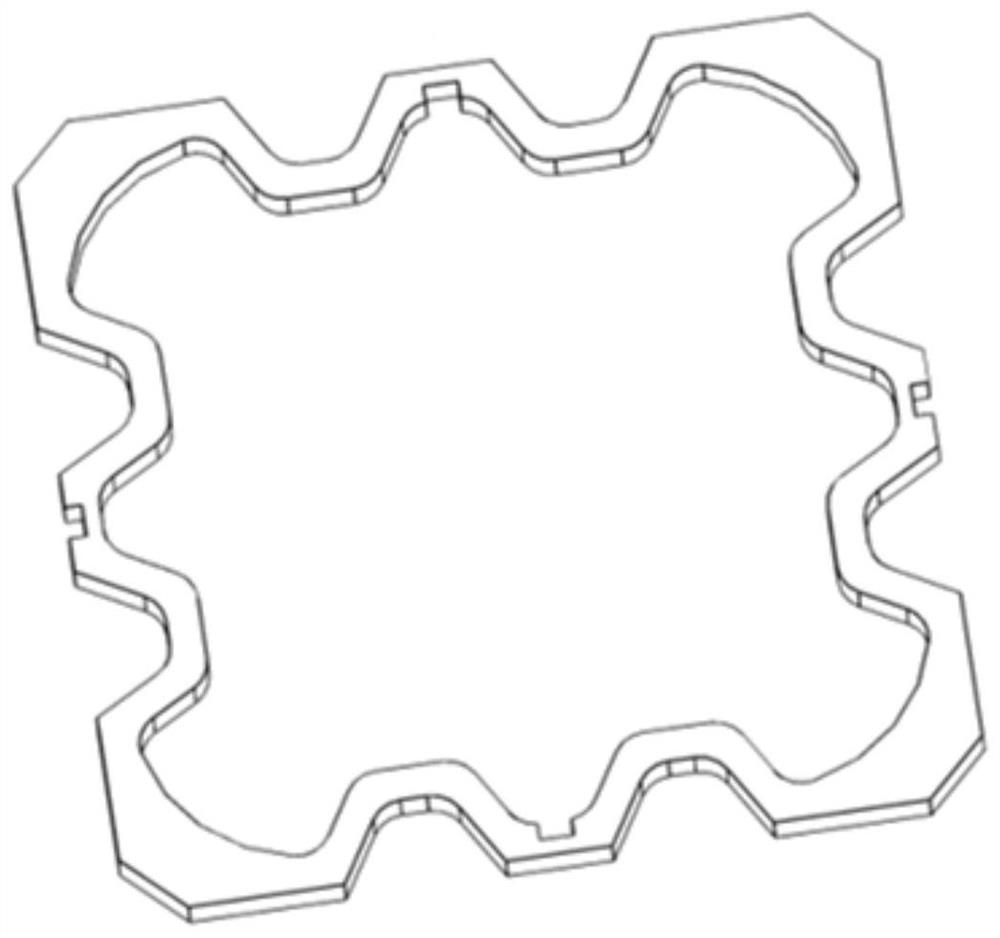

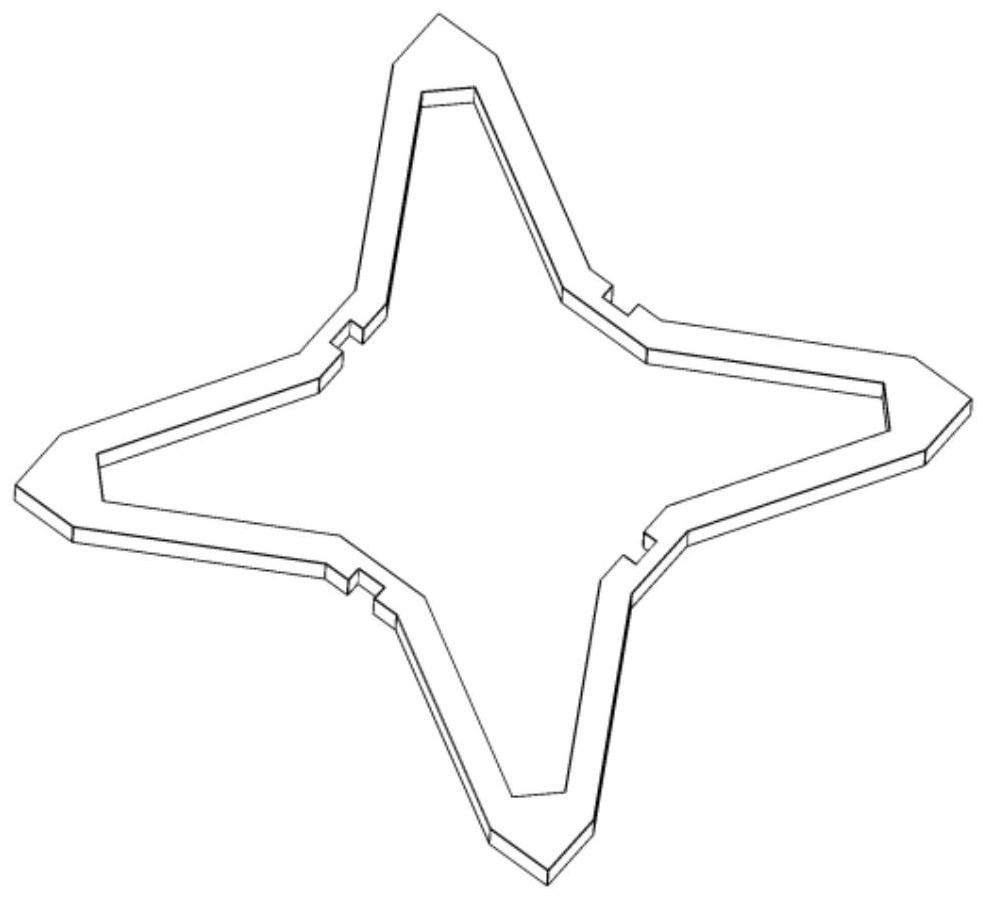

Three-dimensional metamaterial functional component and manufacturing method thereof

ActiveCN114523662ARealize structural deformationSimple structureIncreasing energy efficiencyAdditive manufacturing processesStructural deformationLaser cutting

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

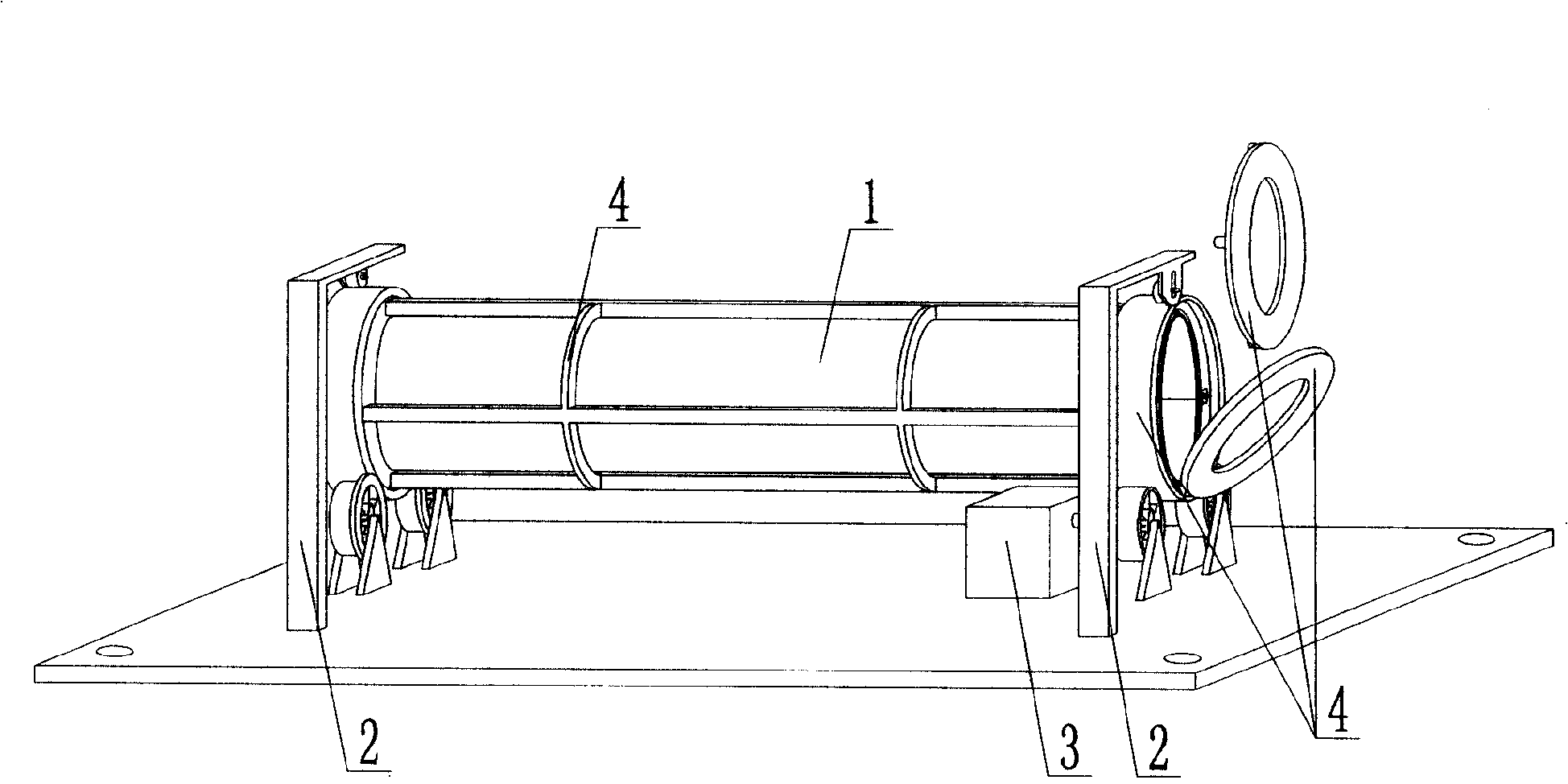

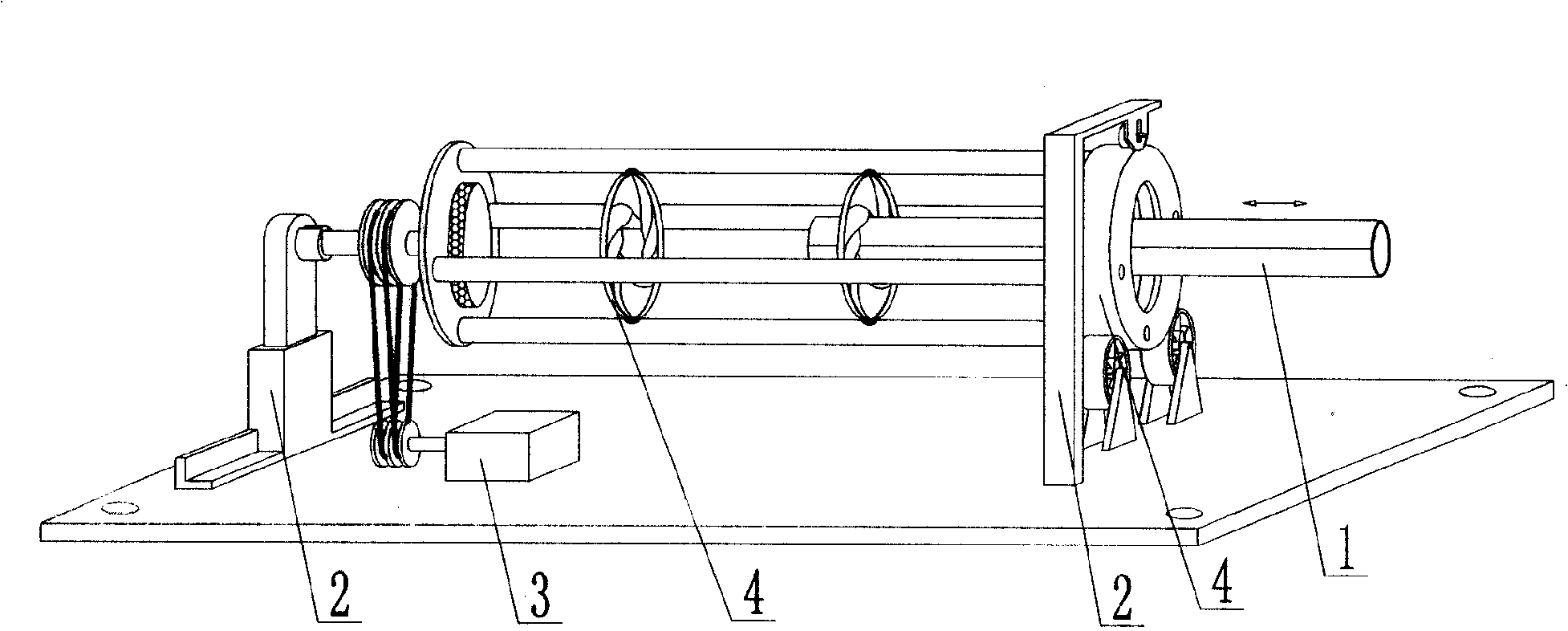

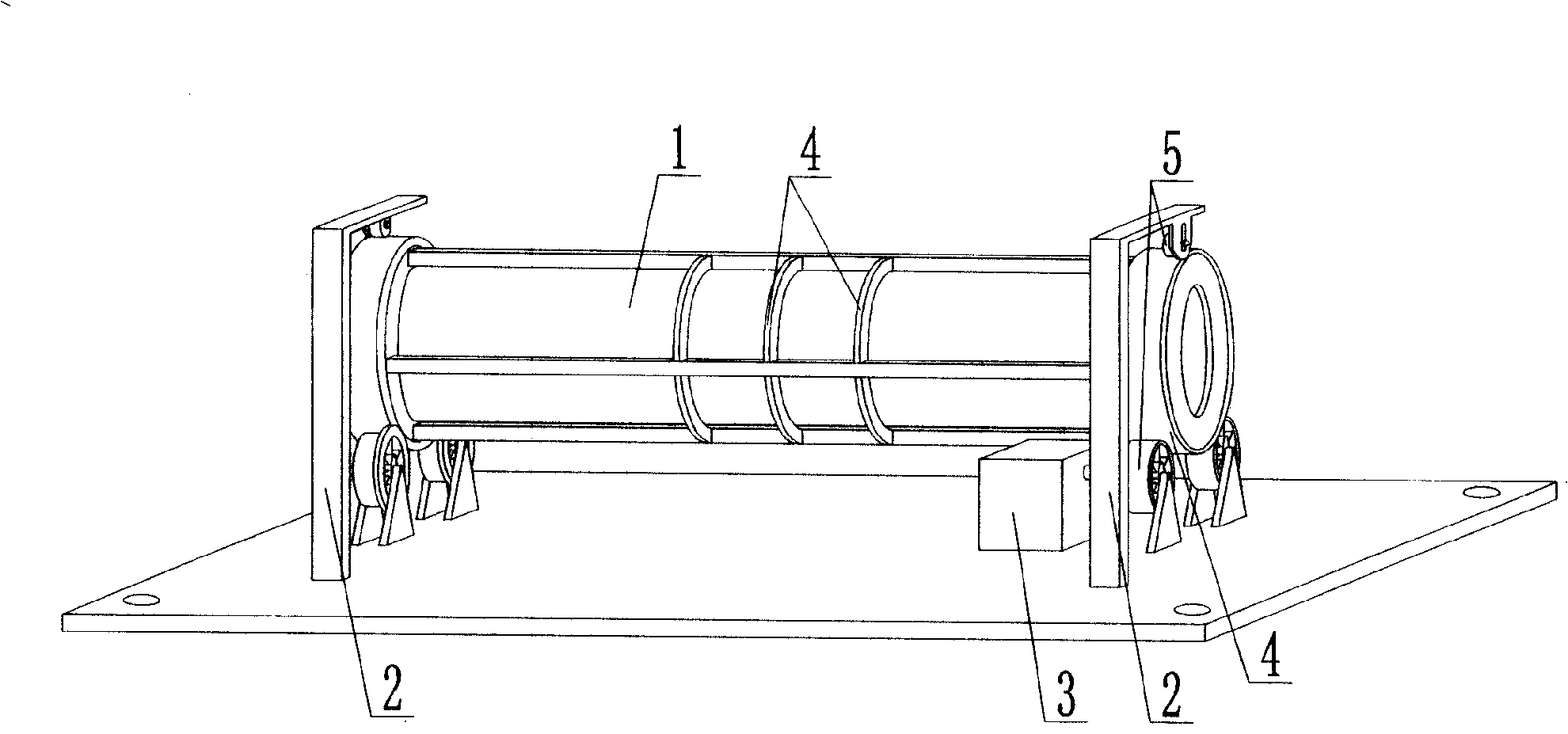

Centrifugal forming tool

Owner:湖南邱则有专利战略策划有限公司

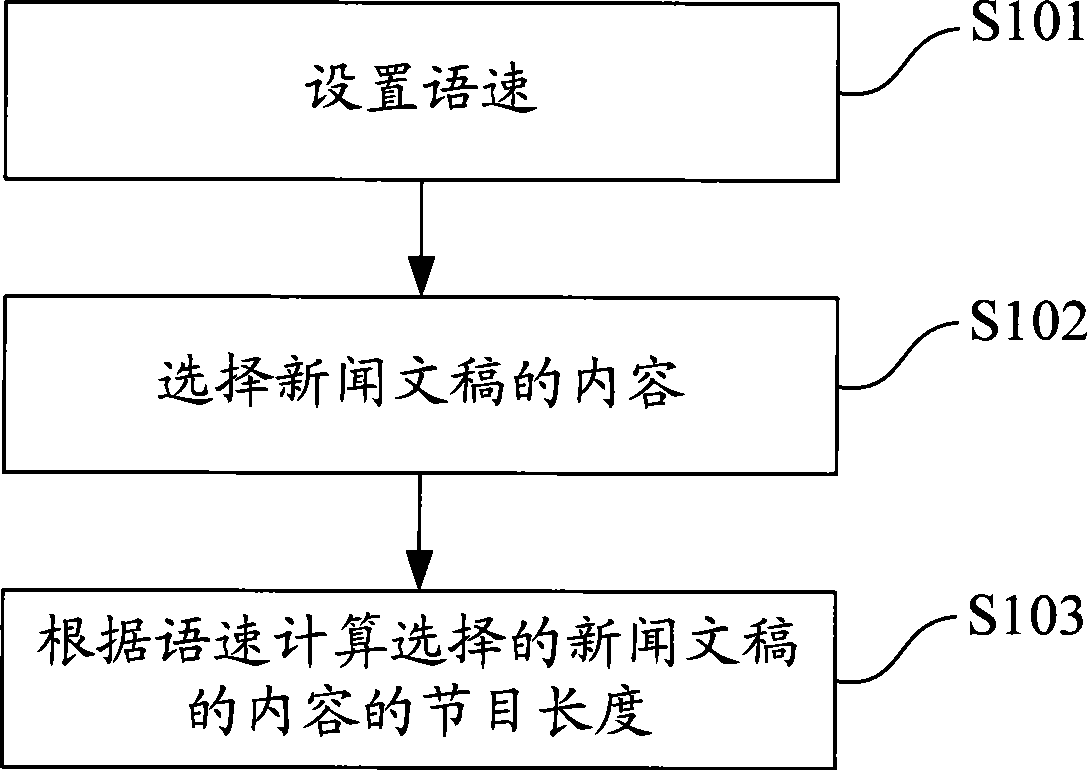

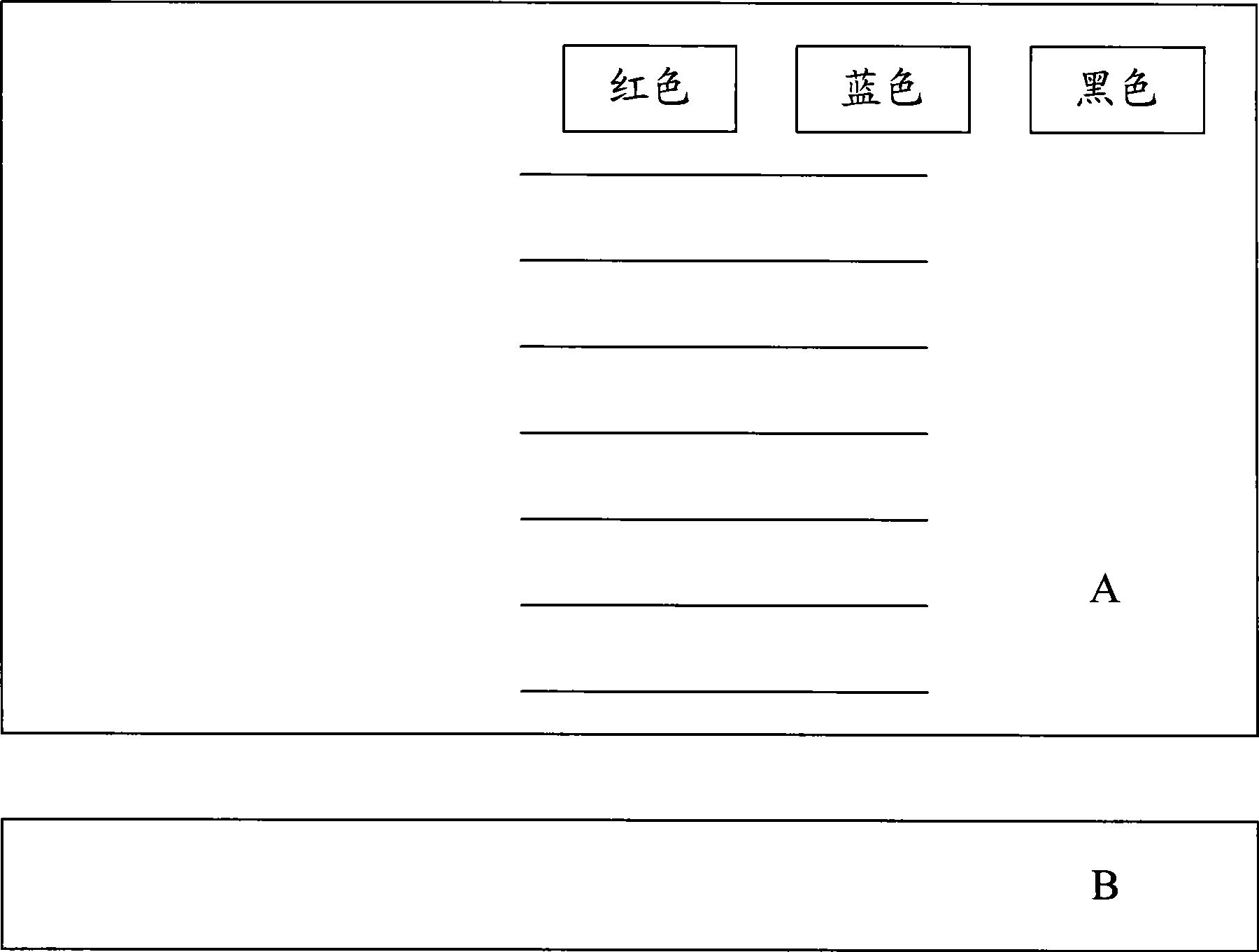

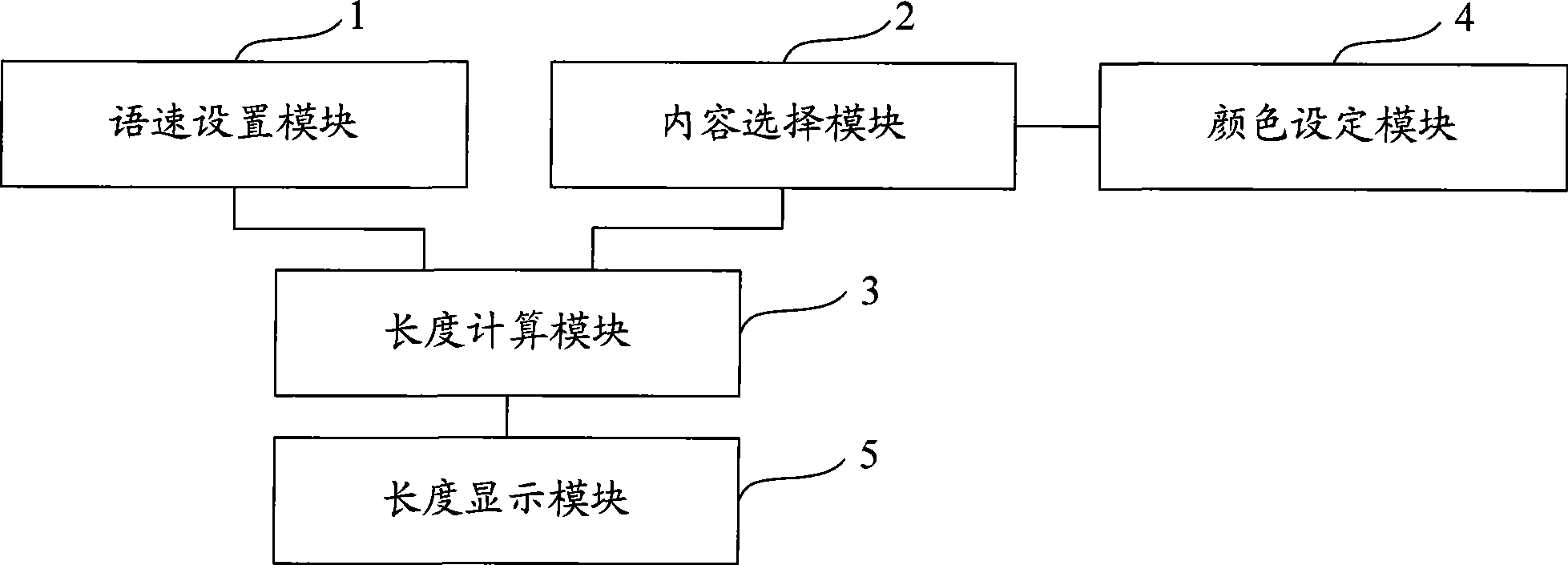

Method and device for estimating news program length

InactiveCN101472060AEstimated word countClose to the lengthTelevision system detailsColor television detailsSoftware engineeringRate of speech

Owner:CHINA DIGITAL VIDEO BEIJING

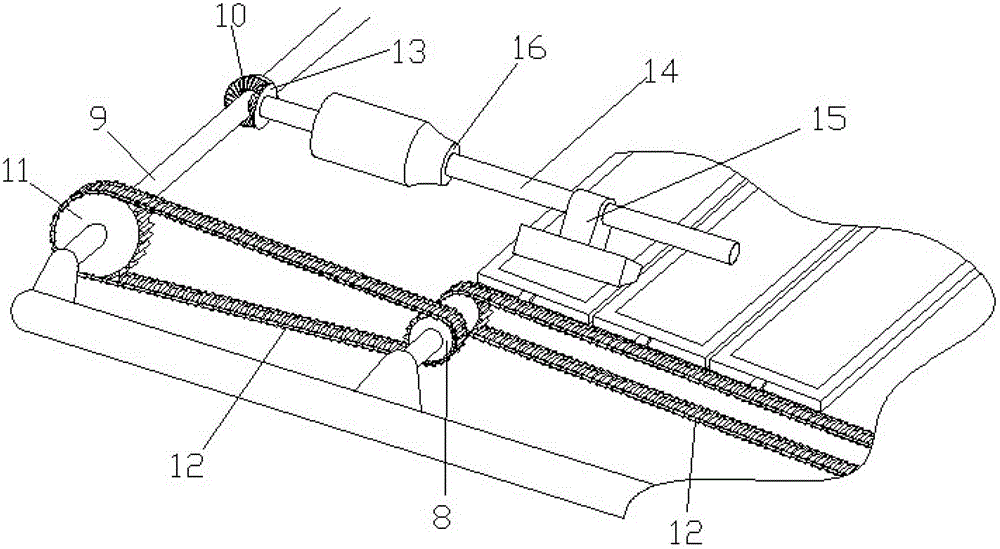

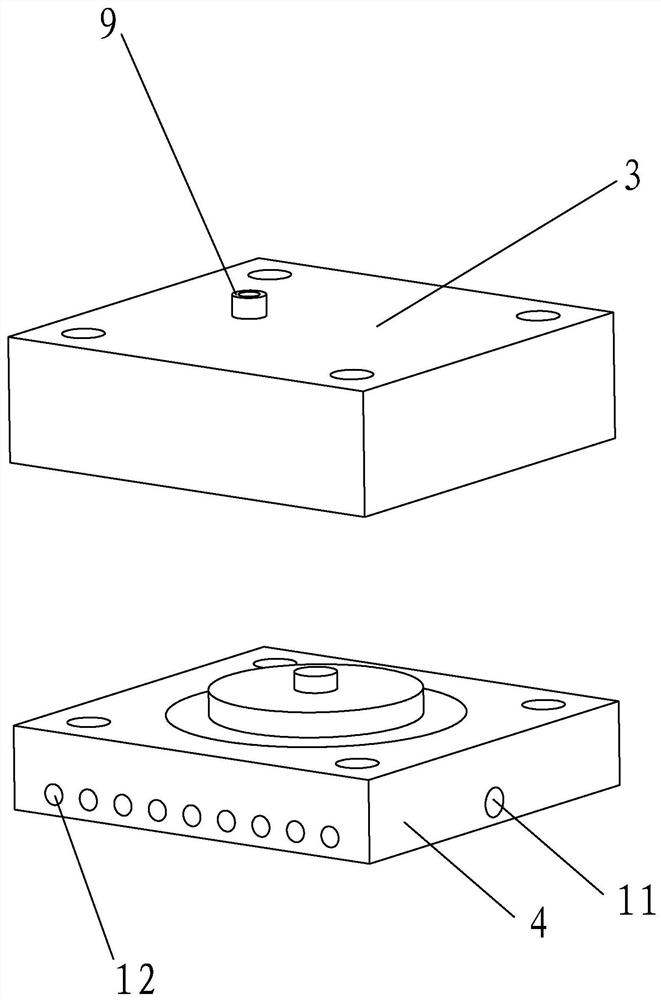

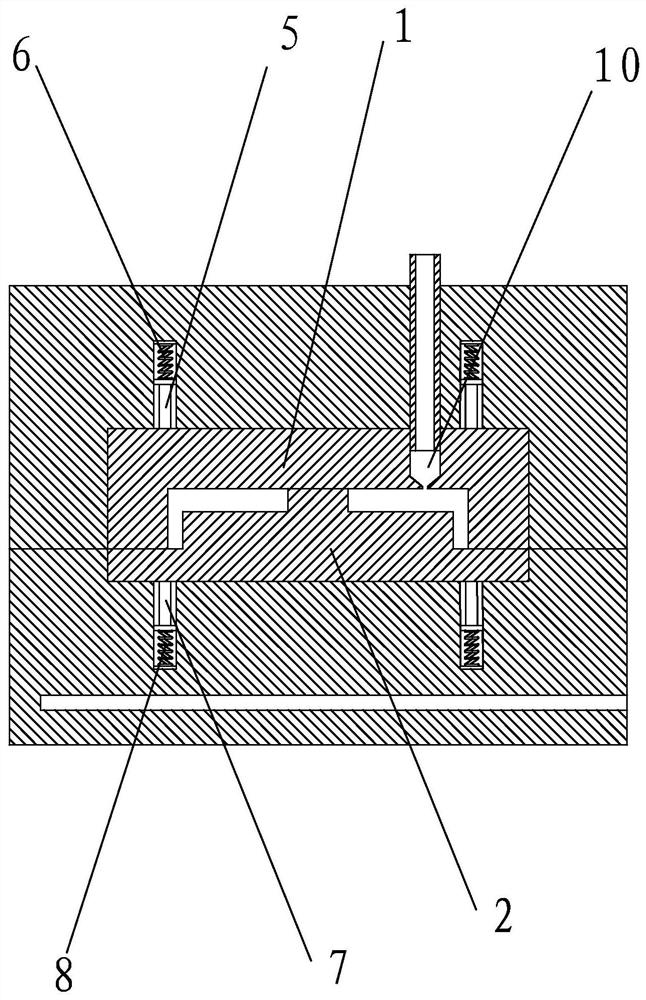

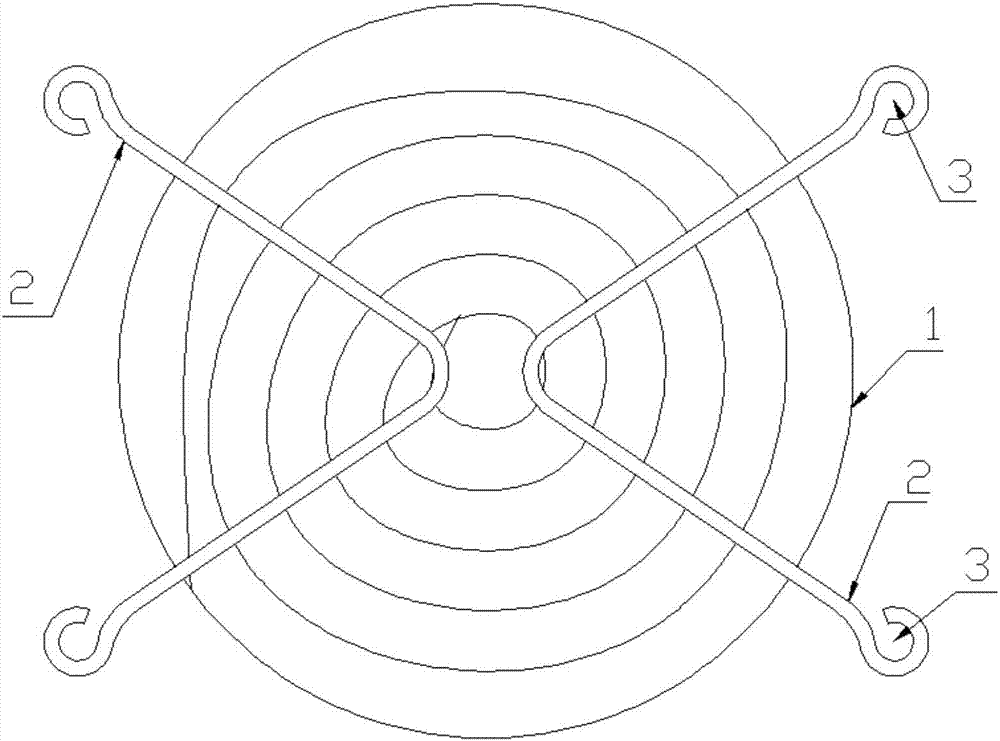

A kind of supporting wheel manufacturing equipment and supporting wheel manufacturing process

ActiveCN111687382BClosed tightlyGuaranteed accuracyFoundry mouldsFurnace typesManufacturing technologyMachined surface

Owner:泉州市宏山工程机械有限公司

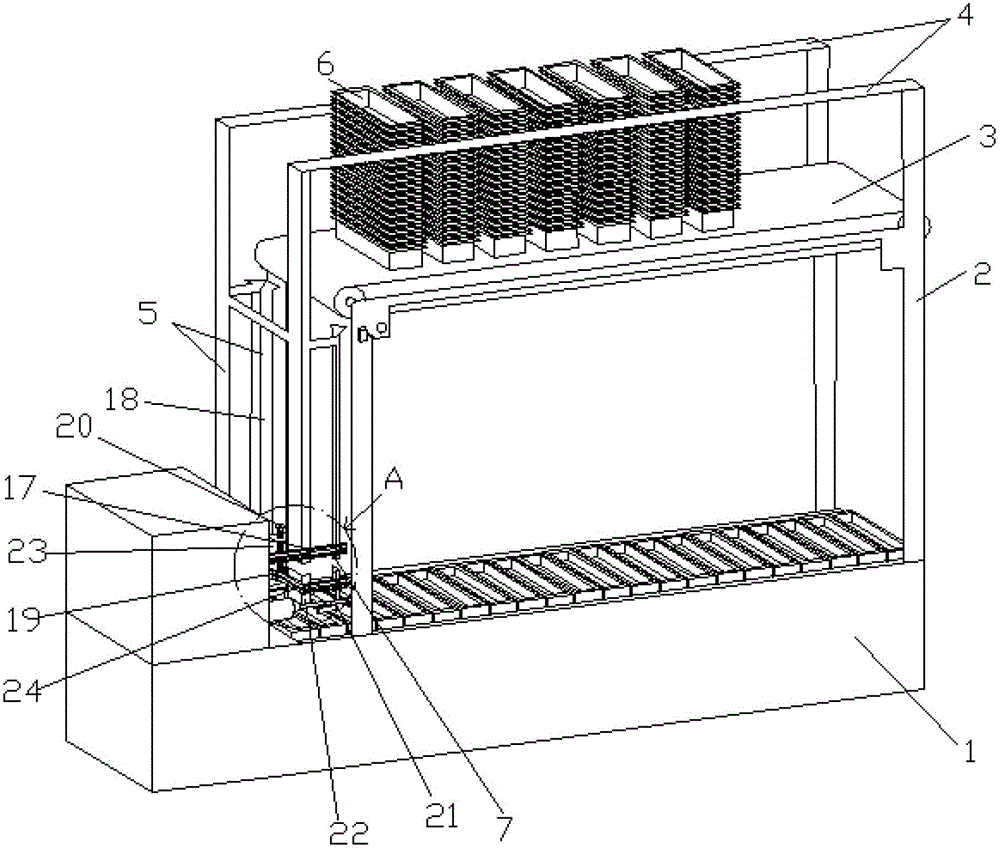

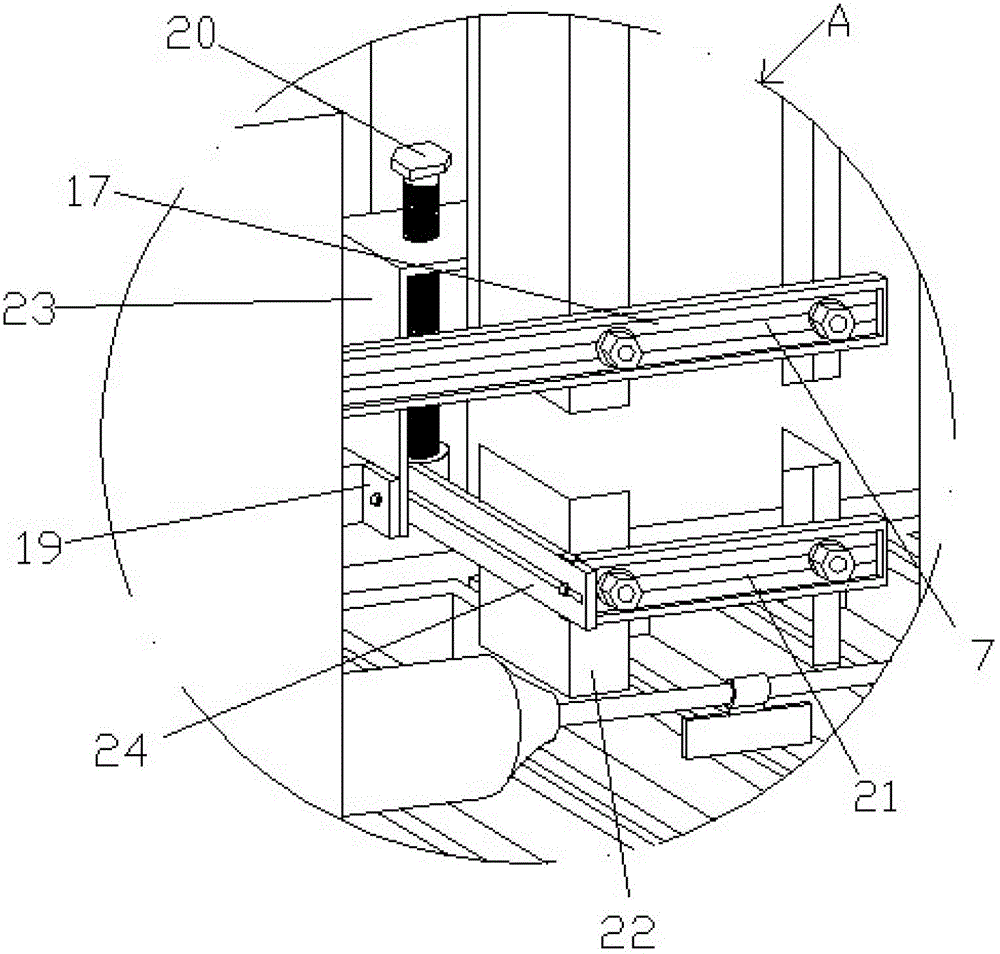

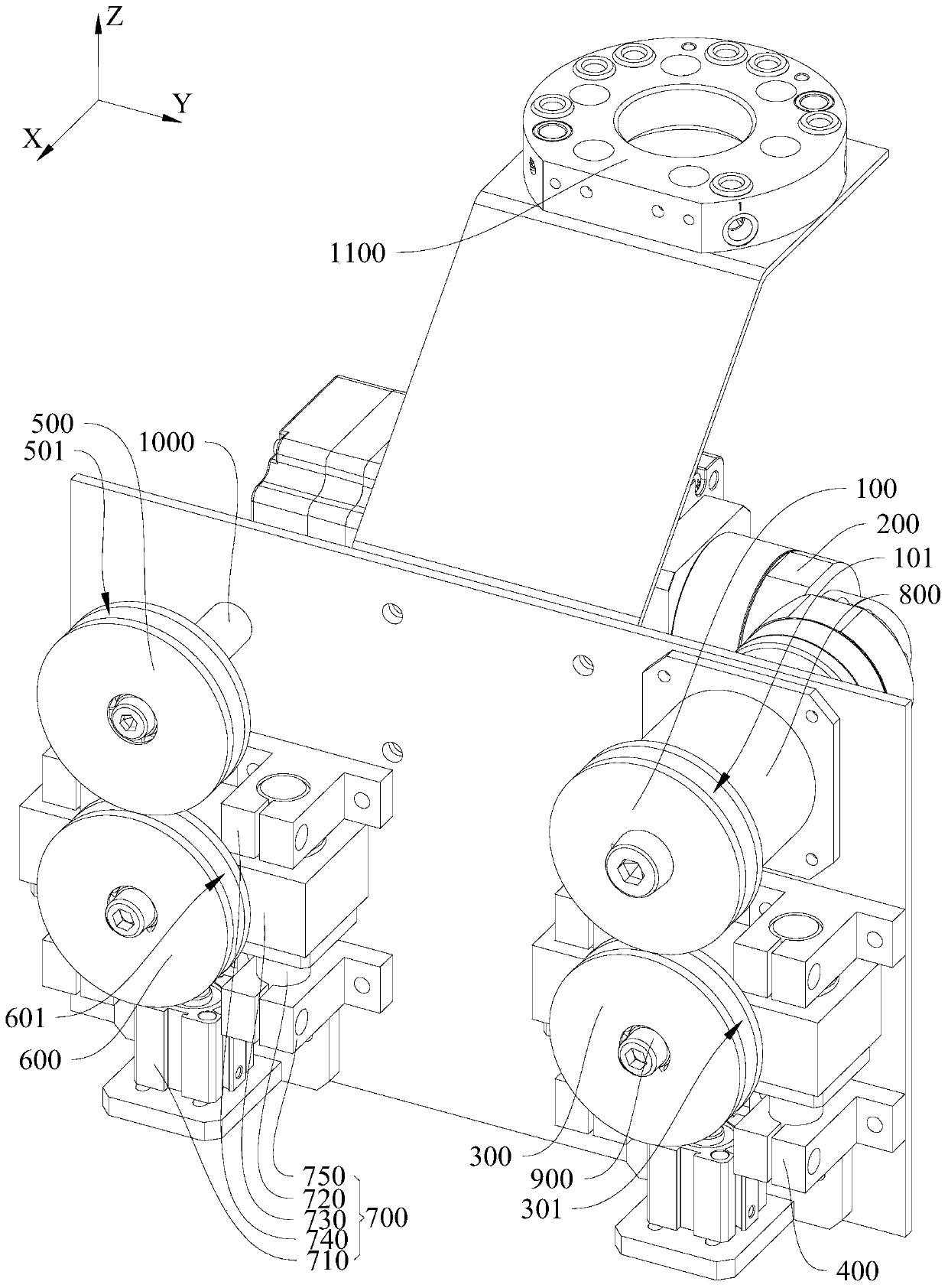

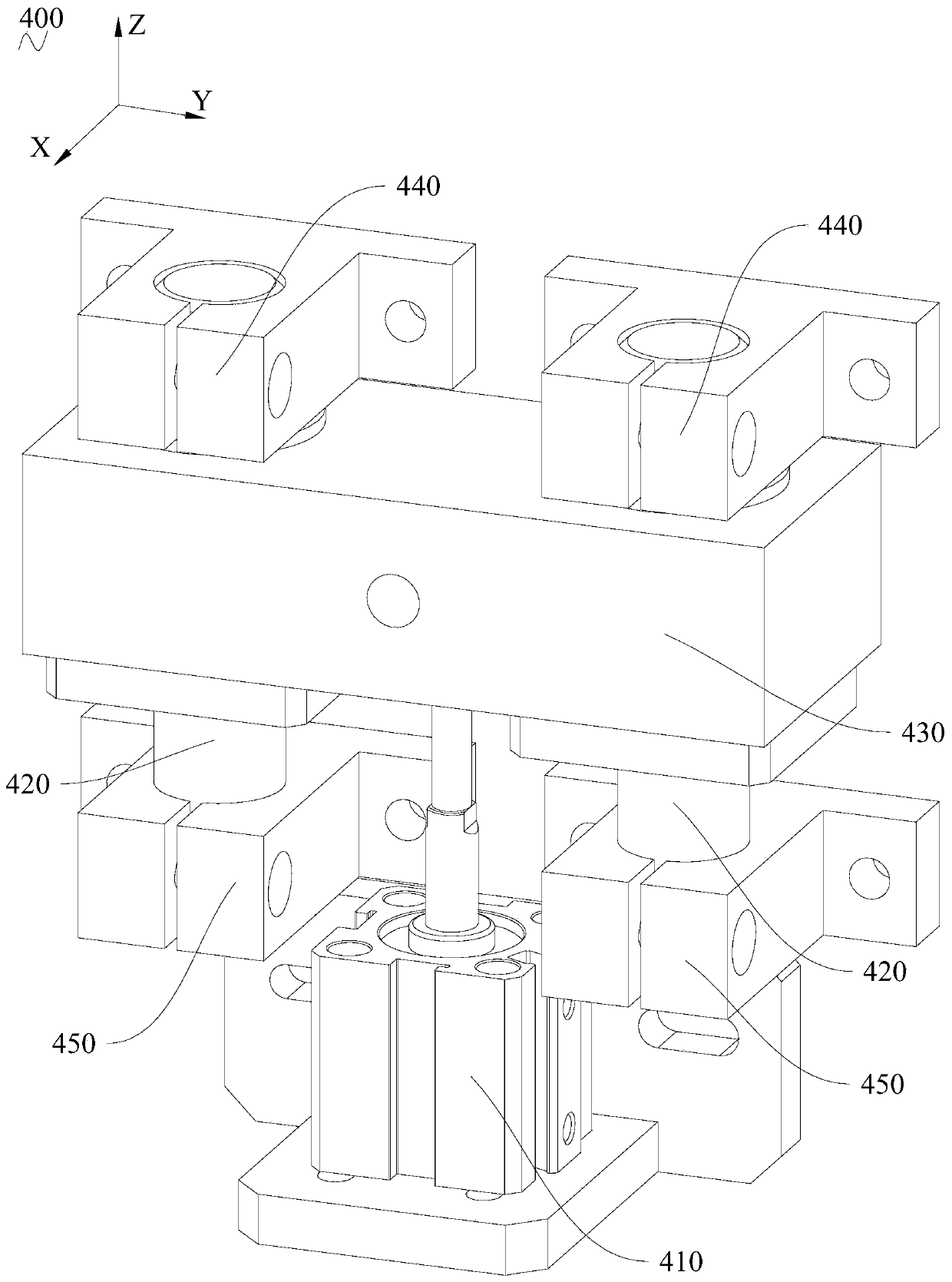

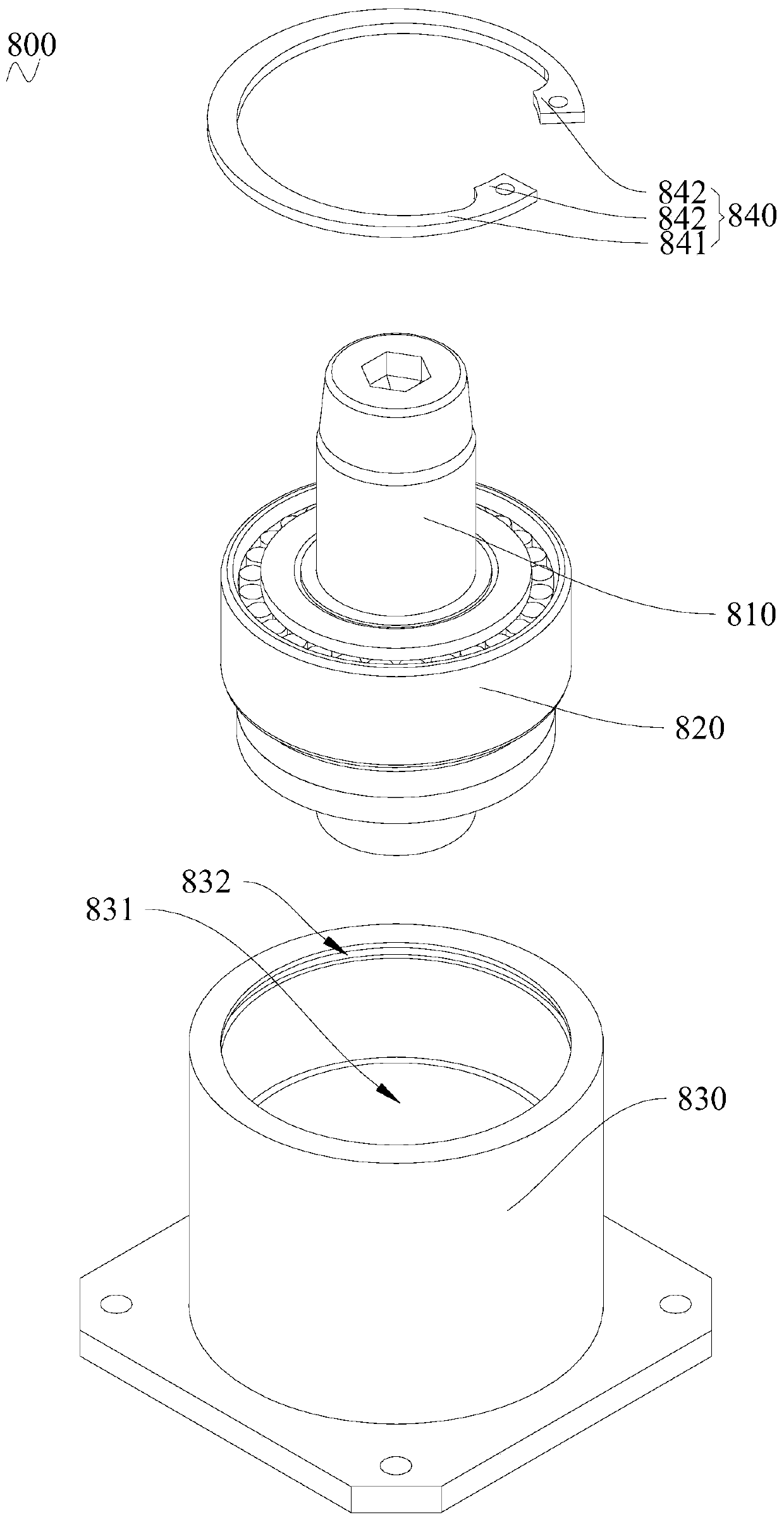

Tail end executing mechanism and longitudinal bar conveying robot

PendingCN110815263ARealize the gripping operationFast throughGripping headsDrive wheelControl engineering

Owner:CHINA CONSTR SCI & TECH CO LTD

Electric appliance cabinet air vent screen

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Reverse vacuum insole setting machine and use method thereof

InactiveCN113116021AMade preciselyFine-tuningFoot measurement devicesInsolesSilicone membraneSilica gel

Owner:沈阳爱山体育发展有限公司

A thyristor

InactiveCN109273361AExtended service lifeEasy to prepareThyristorSemiconductor/solid-state device manufacturingThyratronSemiconductor

Owner:NANTONG MINICHIP MICRO ELECTRONICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap