Automatic box-dropping device for shaped and boxed beancurd processing device

A processing equipment and box-dropping technology, which is applied to the field of automatic box-dropping devices for forming boxed tofu processing equipment, can solve the problems of high labor intensity and low production efficiency of workers, and achieves simple structure, reduced production costs, and reduced labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

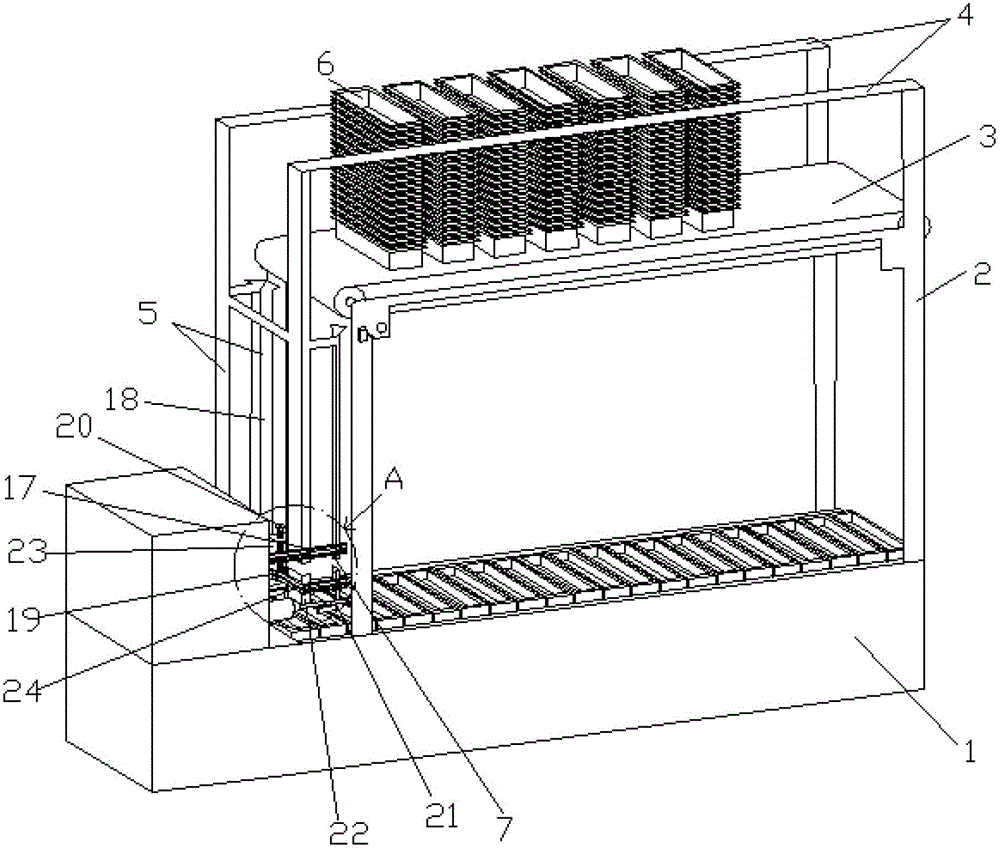

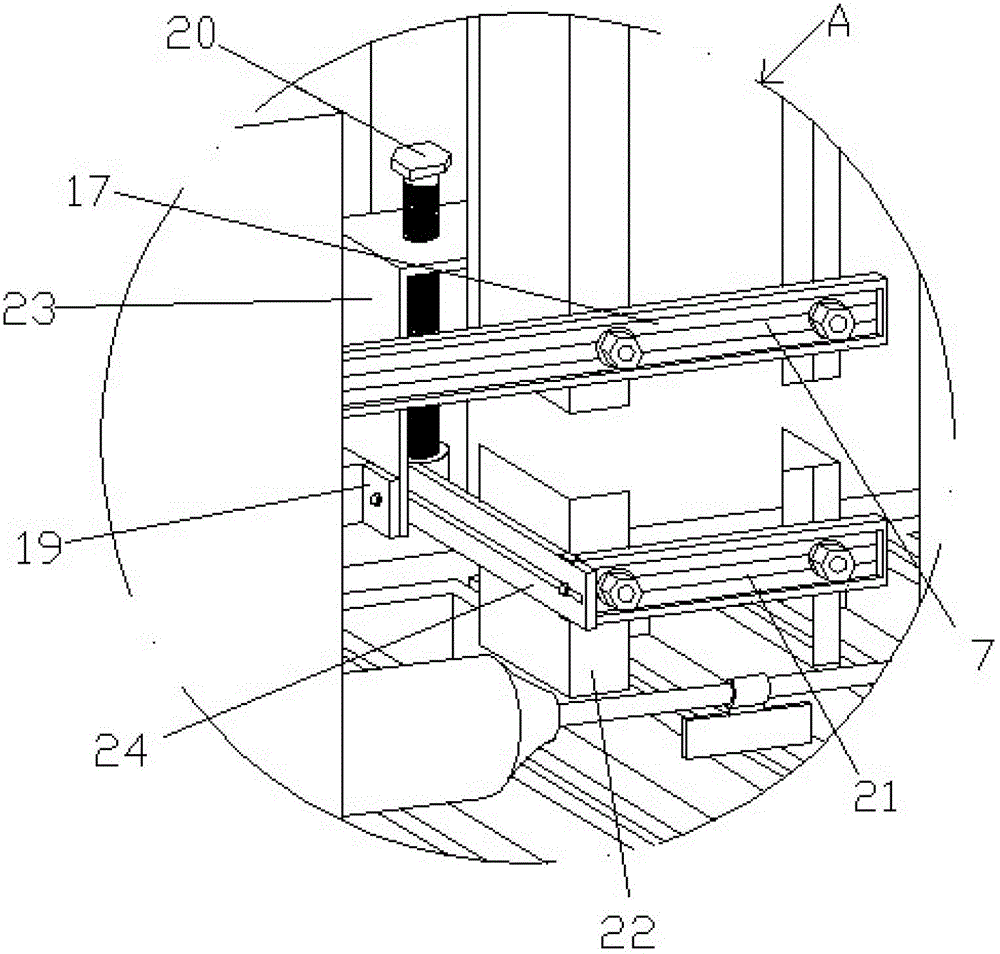

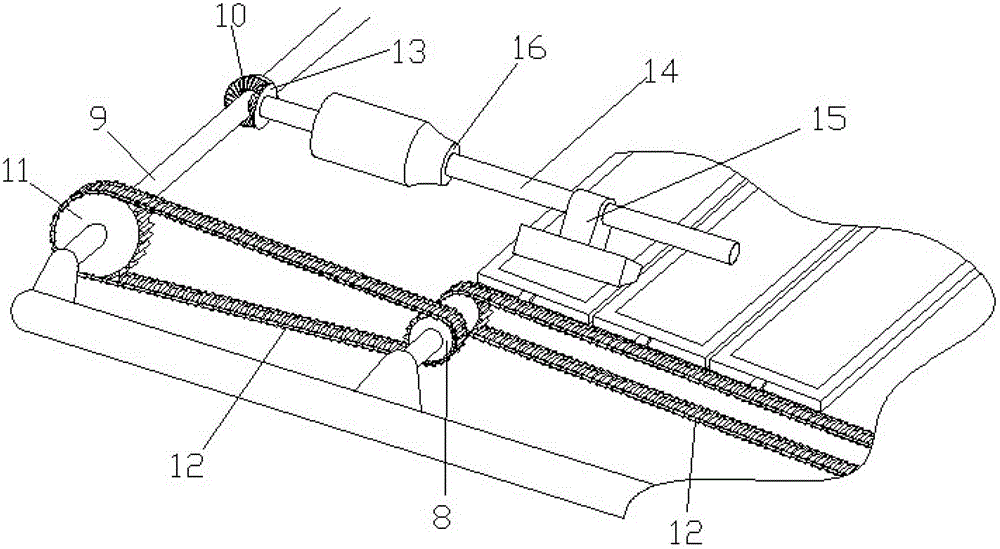

[0029] Such as Figure 1~3 Shown, a kind of automatic drop-box device for forming boxed tofu processing equipment, described automatic drop-box device is arranged on the front end of workbench 1, and described automatic drop-box device comprises the frame 2 that is installed on workbench 1 top, installs The box feeding mechanism used to transport the tofu plastic box 6 on the upper part of the frame 2, the box setting mechanism arranged at the delivery end of the box feeding mechanism, the reduction transmission mechanism installed on the lower side of the frame 2, and the lower part of the frame 2 And the drop box mechanism driven by the reduction transmission mechanism.

[0030] The box feeding mechanism is mainly composed of plastic box conveyor belts 3 arranged horizontally.

[0031] The box setting mechanism includes two cantilever arms 4 and four plastic box guide corner posts 5; the two cantilever arms 4 are installed on the frame 2 apart from each other, and every two of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap