Kit, support frame and manufacturing method thereof

A kit and insert technology, applied in the field of medical devices, can solve problems such as low production efficiency and poor molding quality, and achieve the effects of improved manufacturing efficiency, reasonable structural design, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

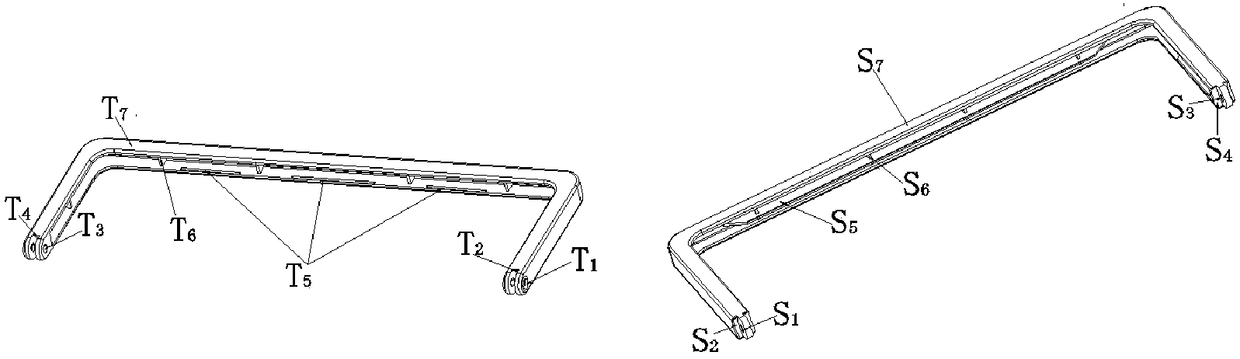

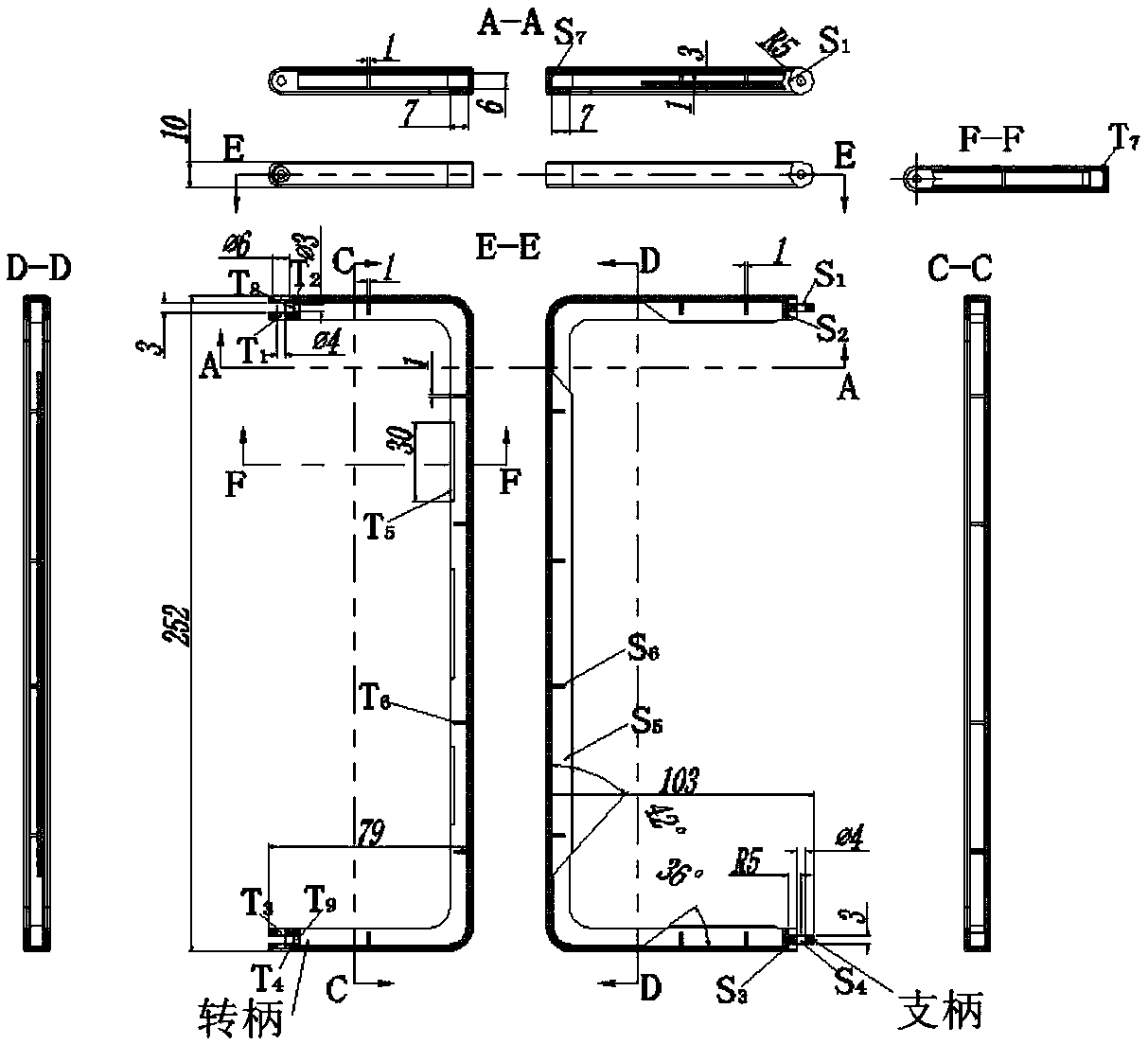

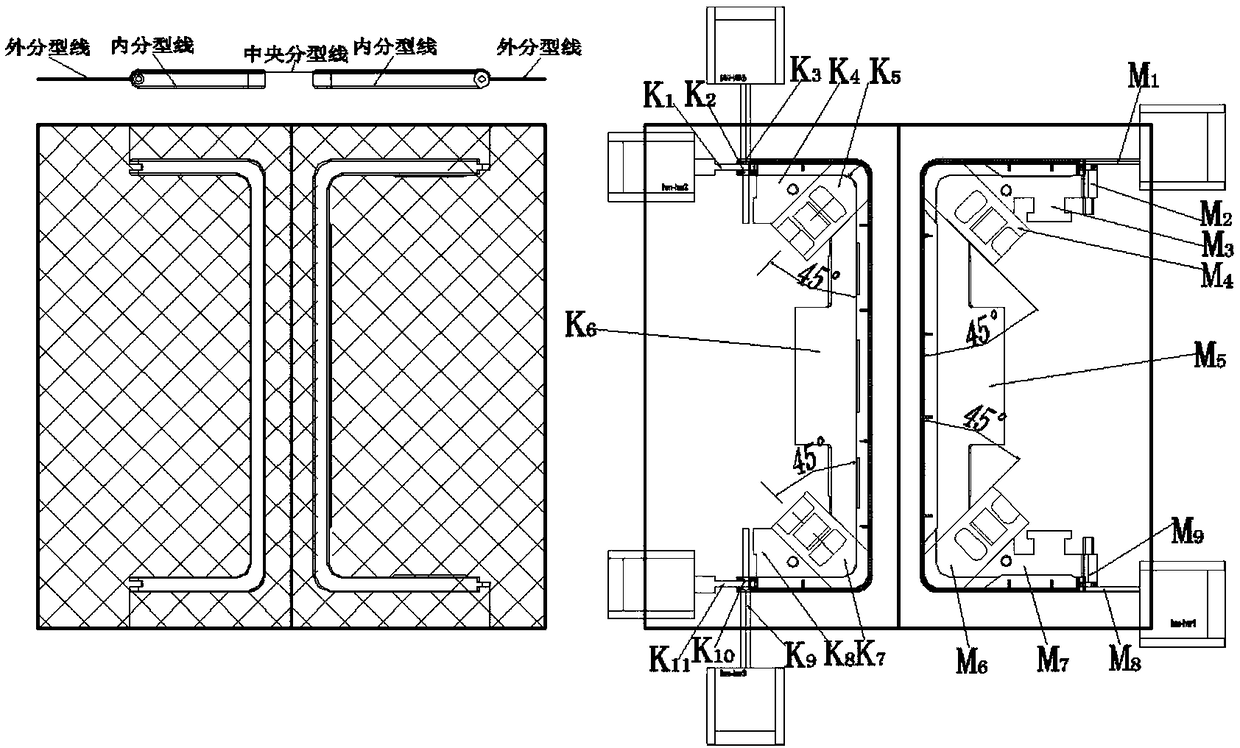

[0020] Figure 1-6 Shown is the relevant explanatory drawing of the present invention; Support frame products such as figure 1 As shown, the material of the product is ABS+PC modified plastic, and the product is a set of products, including the handle and bracket; the shape of the handle is as follows figure 1 As shown, the shape of the bracket is as figure 1 As shown; when using injection molding, the features related to the design of the demoulding mechanism on the two products are seven features T1~T7 in the handle, and seven features S1~S7 on the bracket; T1, T3, S1 , S3 are hinged holes for two parts to be plugged in; T2, T4, S2, S4 are corresponding rotating arc grooves; T5, S5 are inner rib protrusions, T6, S6 are reinforcing transverse ribs; T7, S7 are measurement-shaped skeletons; There are also T8 and T9 through holes at the positions of the turning handles T2 and T4; during injection molding, the mode of the demoulding mechanism that needs to be designed is related t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap