Magnetothermal effect-based magnetic field measurement method, magnetic field sensor and preparation method

A magnetic field sensor and magnetic field measurement technology, which is applied in the direction of the size/direction of the magnetic field, can solve the problems that are not suitable for high-frequency and high-amplitude magnetic field measurement, and the magnetic field range is small, and achieve simple structure, change sensitivity, and optimize size design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

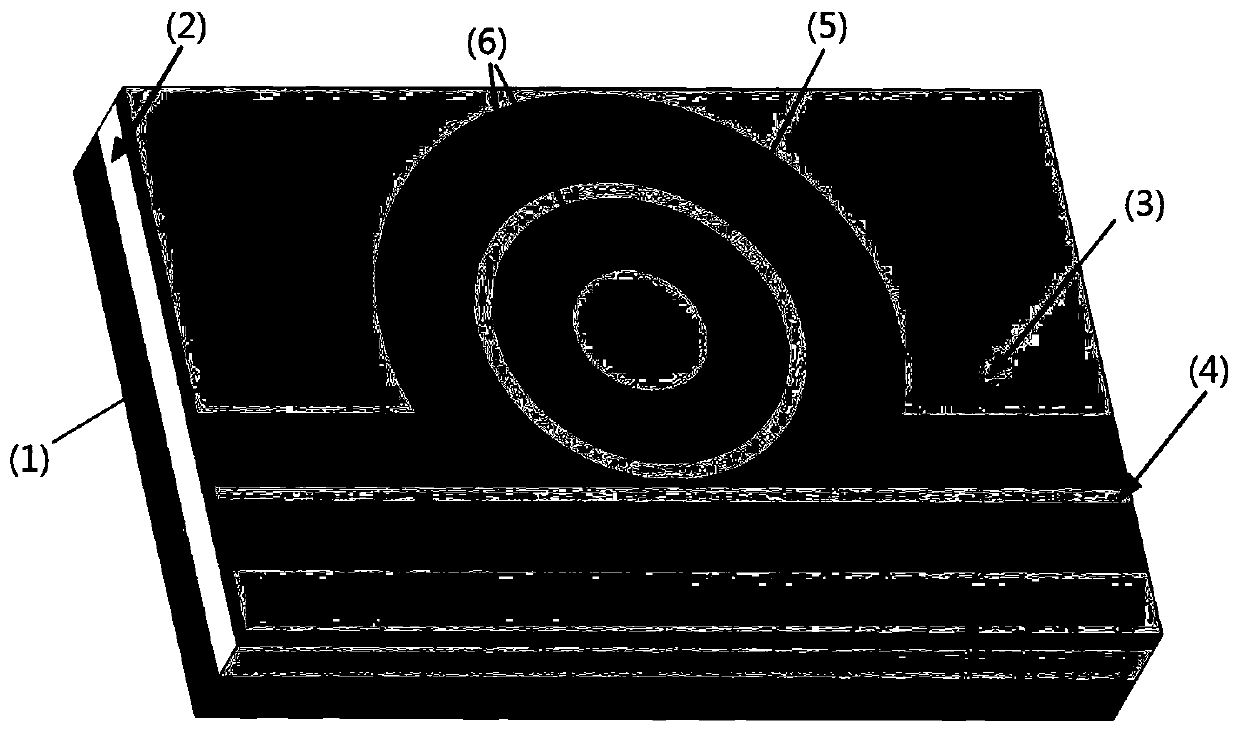

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

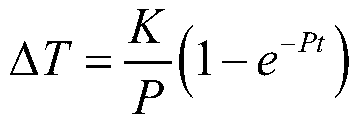

[0025] This embodiment proposes a magnetic field measurement method based on the magnetocaloric effect. Specifically, an optical waveguide is placed in the magnetic field to be measured, and ferric oxide nanoparticles are filled on both sides of the optical waveguide, and the initial temperature of the ferric oxide nanoparticles is obtained. Apply the transverse electric TE or transverse magnetic TM fundamental mode polarization state at the input end of the optical waveguide and monitor the temperature change of the ferroferric oxide nanoparticles in real time, and obtain the magnetic field strength according to the following formula:

[0026]

[0027] Among them: ΔT

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap