Process for extracting commercial grease by tanning lipid-containing waste liquor

A technology of grease and waste liquid, which is applied in the technical field of extracting industrial grease from tanning fat-containing waste liquid, can solve the problems of high operating cost, complex process, and increased enterprise cost, and achieve low operating cost, simple process, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

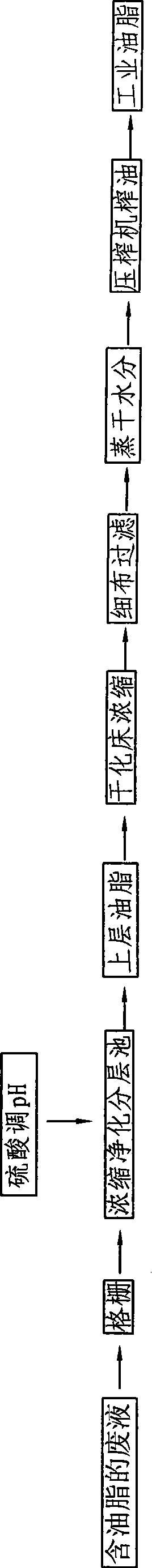

[0020] Such as figure 1 As shown, (1) collect the salt peel fresh water lotion, degreasing water lotion, deliming softening solution, etc. that contain waste oil in tanning production, filter the above waste liquid through a grid with a grid hole diameter of 2mm, and enter the concentrated Purification stratified pool;

[0021] (2) adding sulfuric acid to the concentration and purification layered pool to stir, adjusting the pH of the solution in the concentration and purification layered pool to be 4, and leaving it to stand for 10 hours to achieve purification and stratification;

[0022] (3) Collect the upper white oil-containing floating liquid of the purification stratification in the concentrated purification stratification pool to the recovery turnover pool with the sewage pump;

[0023] (4) Use the caliber 80mm, 3kw, and flow rate of 42m to recover the fat-containing liquid from the turnover pool 3 The / h submersible sewage pump is installed in the turnover pool, sent

Embodiment 2

[0027] Such as figure 1 As shown, (1) Collect the salt peel fresh water lotion, degreasing water lotion, deliming softening solution, etc. that contain waste oil in tanning production, filter the above waste liquid through a grid with a grid hole diameter of 3mm, and enter the concentrated Purification stratified pool;

[0028] (2) Add sulfuric acid to stir in the concentration and purification layered pool, adjust the solution pH in the concentration and purification layered pool to be 5, leave standstill for 20h, and reach the purification layer;

[0029] (3) Collect the upper white oil-containing floating liquid of the purification stratification in the concentrated purification stratification pool to the recovery turnover pool with the sewage pump;

[0030] (4) Use the caliber 80mm, 3kw, and flow rate of 42m to recover the fat-containing liquid from the turnover pool 3 The / h submersible sewage pump is installed in the turnover pool and sent to the drying bed. The drying

Embodiment 3

[0034] Such as figure 1 As shown, (1) collect the salt peel fresh water lotion, degreasing water lotion, deliming softening solution, etc. that contain waste oil in tanning production, and filter the above waste liquid through a grid with a grid hole diameter of 2.5 mm, and enter Concentrated and purified stratified pool;

[0035] (2) Add the sulfuric acid after diluting and cooling first in the concentration and purification stratification tank to stir, adjust the pH of the solution in the concentration and purification stratification tank to be 4.5, leave standstill for 15h, and reach the purification and stratification;

[0036] (3) Collect the upper white oil-containing floating liquid of the purification stratification in the concentrated purification stratification pool to the recovery turnover pool with the sewage pump;

[0037] (4) Use the caliber 80mm, 3kw, and flow rate of 42m to recover the fat-containing liquid from the turnover pool 3 The / h submersible sewage pu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap