Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Binding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Binding Process. Index. Binding a guitar is the process of cutting a channel along the edge of the body, and gluing in a (typically) plastic strip. The purpose of this is primarily to hide all the end grain of the top and bottom of the guitar.

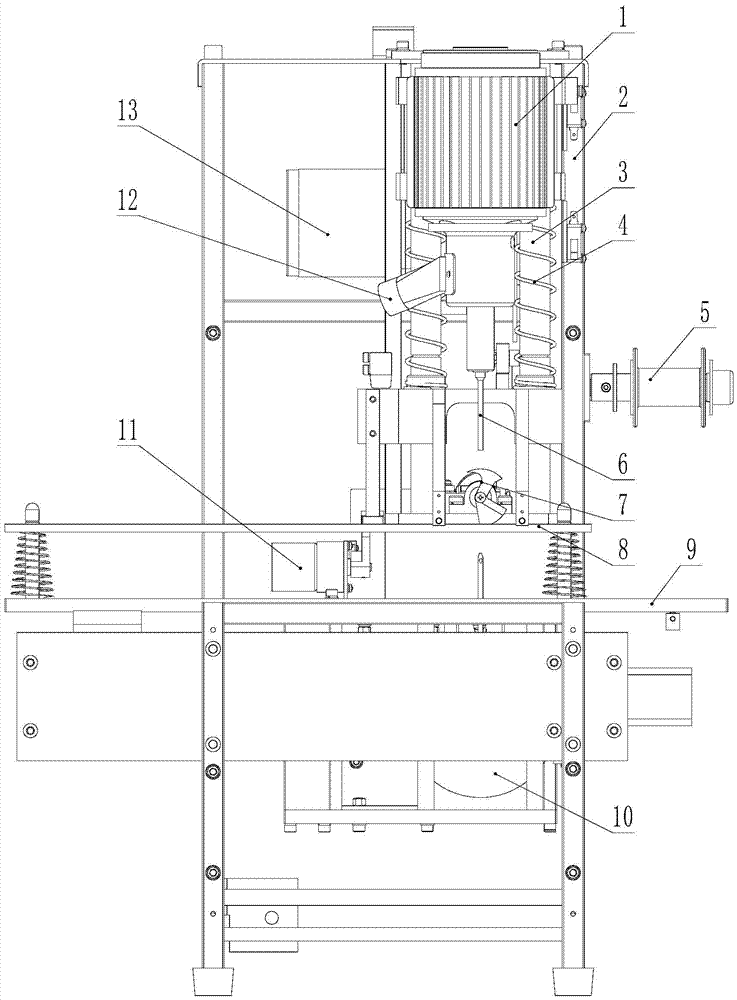

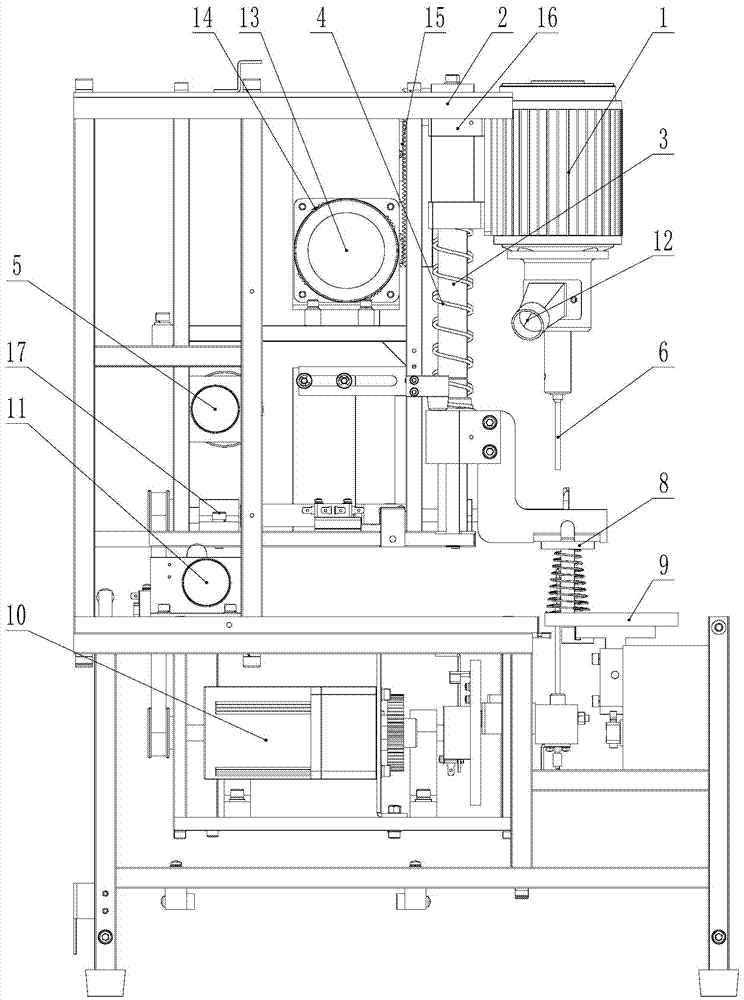

Wire type completely intelligent bookbinding machine

Owner:ZHONGCHAUNGEN TIANJIN TECH CO LTD

Conductive film and touch screen

In the present invention, the base material in the conductive film includes an integrally formed first part and a second part, the first part includes a touch sensing area and a frame area, and the second part extends outward from at least one side of the first part At least one flexible connection part is formed, and the sensing electrode leads and the driving electrode leads are respectively extended to the ends of each flexible connection part to form a first plug-in structure and a second plug-in structure containing electrode leads, so as to form a plug-in type structure, so that it is not necessary to bind an additional flexible printed circuit board on the touch sensing layer when it is connected with the main board or other components through a connector, so it is unnecessary to use expensive flexible printed circuit boards and avoid flexible printed circuit boards. Poor contact and poor reliability of subsequent samples are likely to occur during the bonding process between the circuit board and the touch sensing layer.

Owner:NANCHANG O FILM DISPLAY TECH CO LTD

Carton manufacturing equipment

InactiveCN109968734AImprove production efficiencyImprove stabilityPaper-makingBox making operationsCartonEnergy consumption

The invention discloses carton manufacturing equipment. The equipment comprises a packaging carton edge sealing machine body, wherein a conveying cavity is formed in the machine body in a left and right penetrating mode, a conveying belt groove with an upward opening is formed in the lower side of the conveying cavity in a communicating mode, conveying rotating shafts are arranged in the conveyingbelt groove in a left-right symmetric mode, the front ends and the rear ends of the conveying rotating shafts are rotationally connected with the front end wall and the rear end wall of the conveyingbelt groove respectively, conveying wheels are fixedly arranged on the conveying rotating shafts, and the conveying wheels are in power connection through a conveying belt. The equipment is simple instructure and convenient to operate, the edge sealing device is used for binding to-be-sealed edges of a packaging carton, in the binding process, a reversing device controls rotation direction of the conveying belt, so that the packaging carton is moved to the right side of the edge sealing device, after the edge sealing device descends to a lifting cavity, the carton retracts to the edge sealing device to be bound, the equipment is used in the later package forming process, and full-automatic packaging and forming of the equipment are achieved. Compared with traditional manual edge sealing,the equipment has the advantages that the time is saved, the carton manufacturing efficiency is high, the edge sealing integrity is good, and the energy consumption is low.

Owner:HANGZHOU ZHIAI PACKAGING PROD CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap