Ground conveyor with electric pump motor

A ground transportation and mechanical technology, applied in the direction of synchronous motors for single-phase current, control of mechanical energy, AC motor control, etc., can solve the problems of alternating reference potential consumption, complicated control devices, etc., and achieve the possibility of small faults, The effect of low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

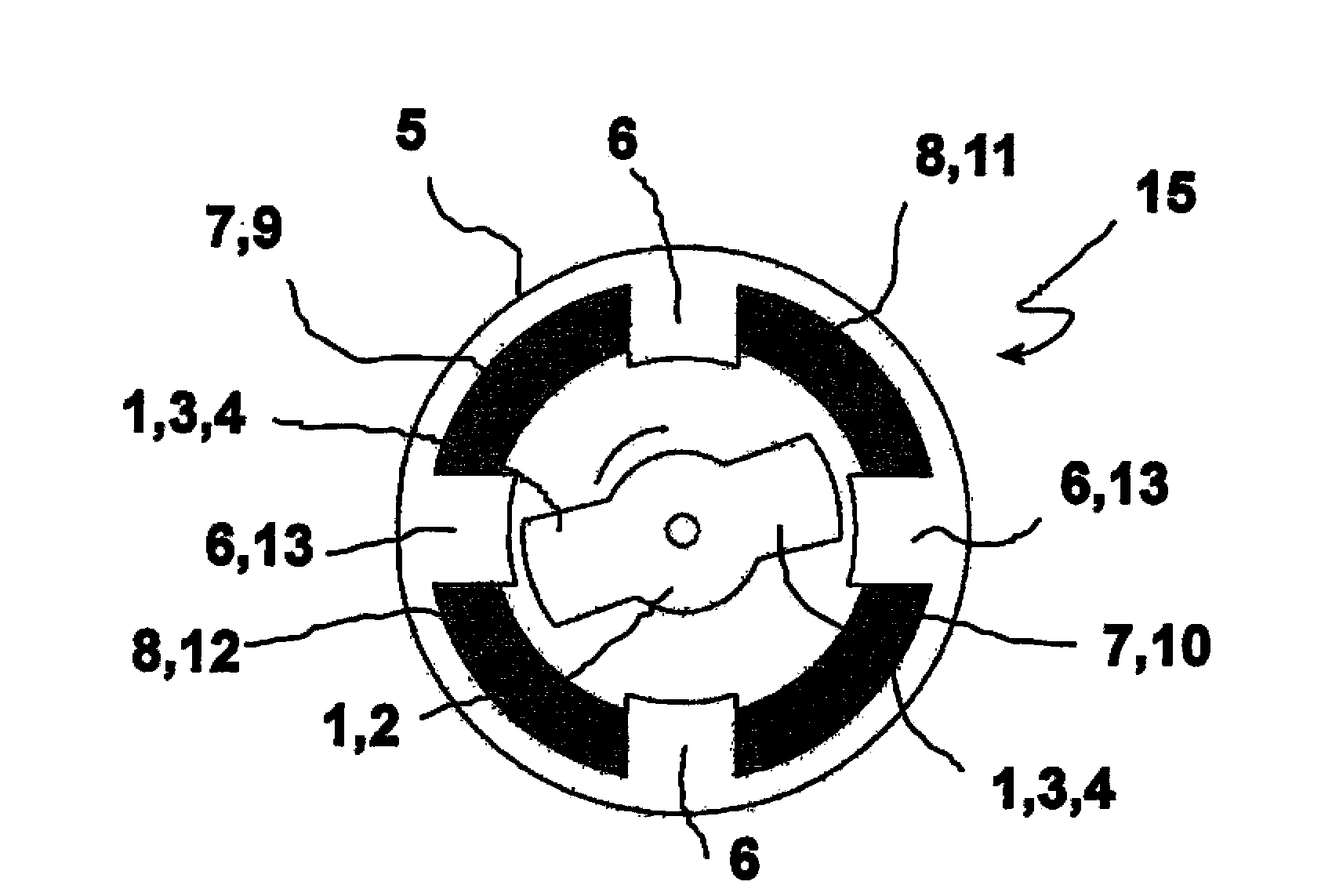

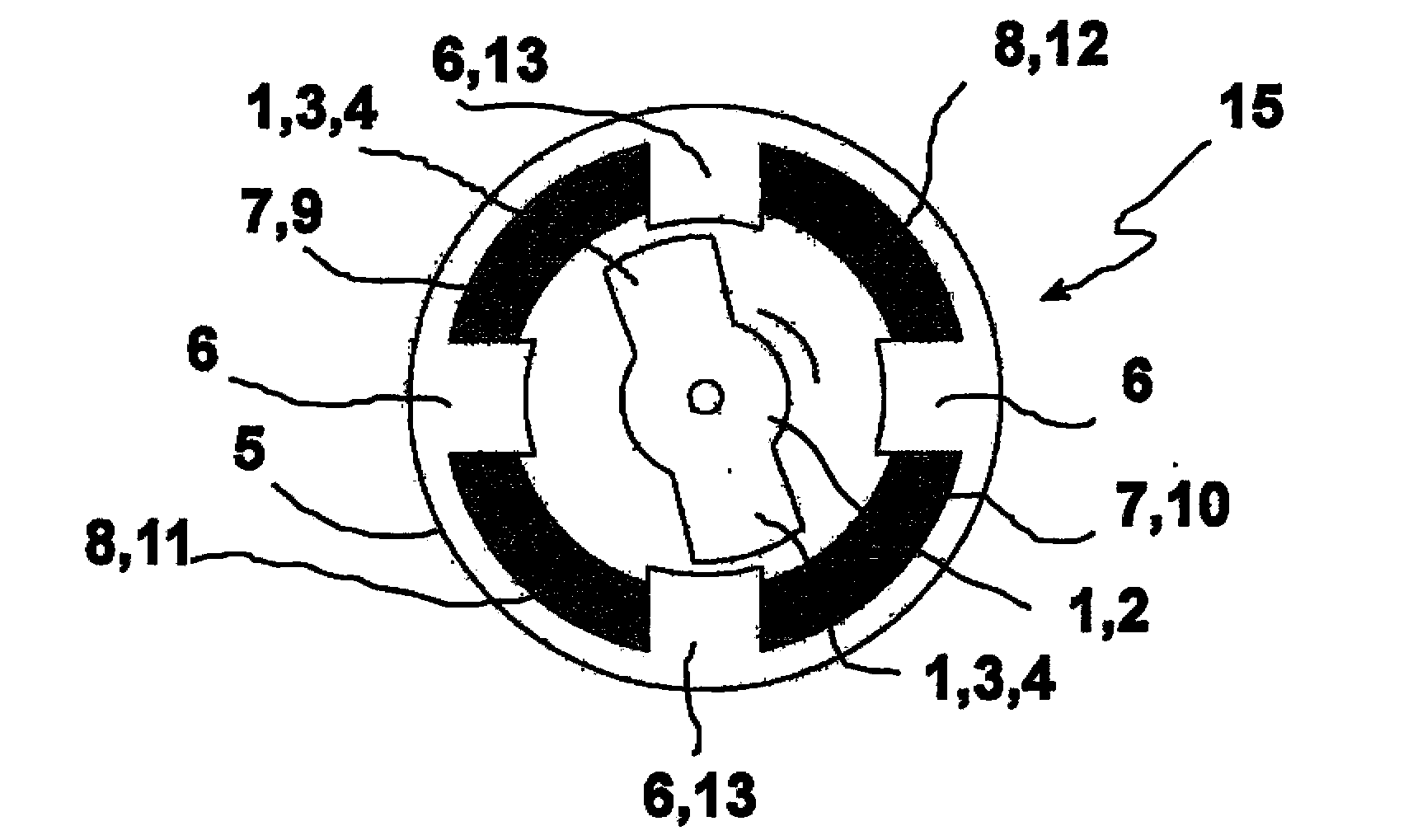

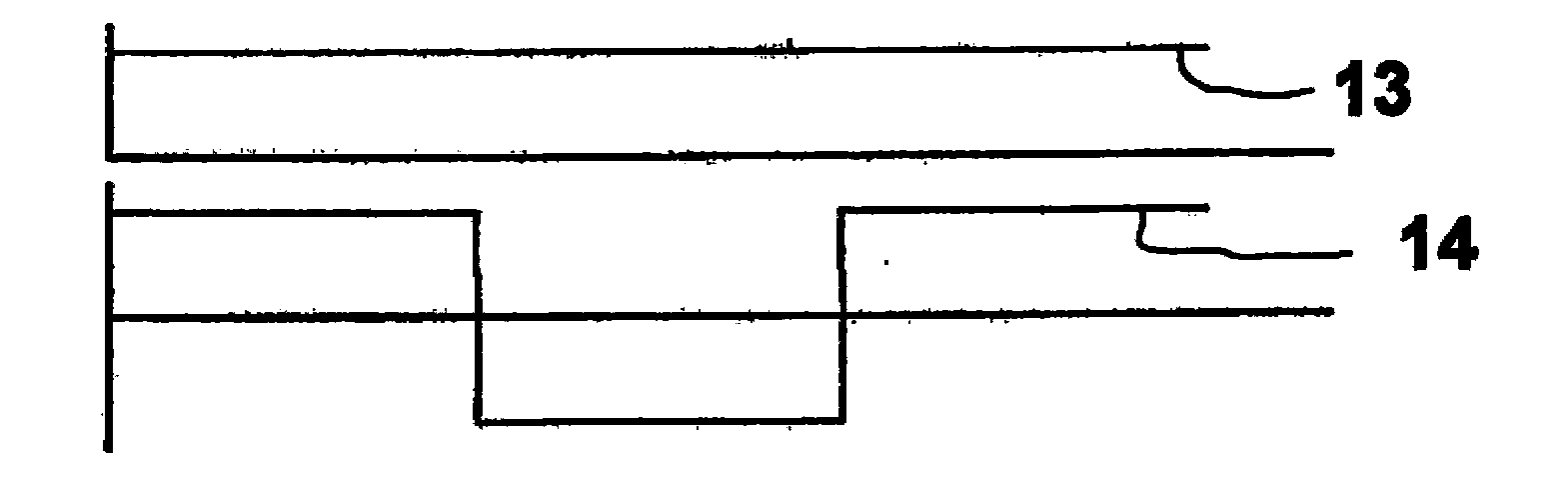

[0038] Figure 1a An exemplary embodiment of a pump motor 15 of a working hydraulic system, which is used in the floor conveyor machine according to the invention, is shown schematically. The rotor 1 comprises a rotor shaft 2 and two segments 3 of soft-magnetic or suitably highly magnetically permeable material, which form rotor poles 4 in the circumferential direction, which attempt to This orientation of the magnetic field is utilized since there is a minimum magnetic reluctance in the orientation of these rotor poles 4 . The stator 5 has a total of four uniformly distributed stator poles 6 , which thus have a graduation of 90°. The field windings 7 each include a pair of stator poles 6 at an interval of 180°. Offset by 90°, the armature windings 8 are likewise arranged with a division of 180°, so that they also each include a pair of stator poles 6 . exist Figure 1a The view in FIG. 2 shows the negative terminal side 9 and the positive terminal side 10 of the field winding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap