Plant protection machine

A technology of planting and protecting machines, applied in control devices, transportation and packaging, vehicle parts, etc., can solve the problems of unstable power output, high cost, low work efficiency, etc., and achieve flexible use of machines, stable power output, and operation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

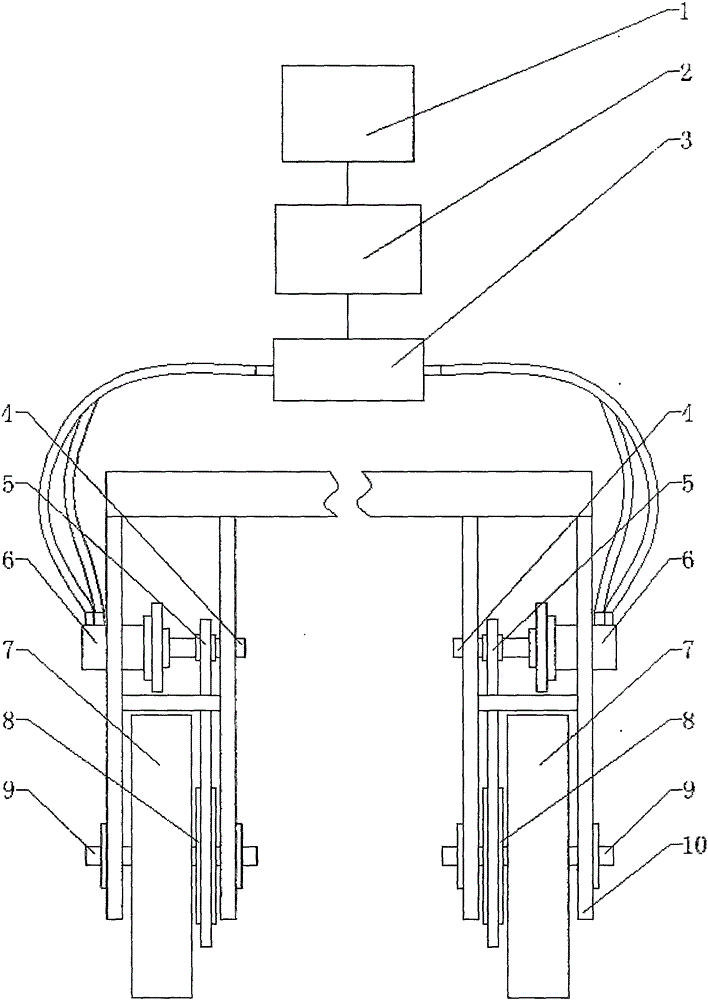

[0018] Embodiment 1: as figure 1 As shown, a plant protection machine includes a frame 10, an engine 1 and a hydraulic pump 2 are arranged above the frame 10, the engine 1 and the hydraulic pump 2 are connected, the hydraulic pump 2 is connected with two hydraulic motors 6 through a distributor 3, and the two Two hydraulic motors 6 are respectively connected in transmission with two traveling wheels 7 below the frame 10. The hydraulic motors 6 are arranged on the frame 10 above the traveling wheels 7, and the two traveling wheels 7 are arranged symmetrically.

[0019] The hydraulic motor 6 has an output shaft 4, the traveling wheel 7 is provided with a transmission shaft 9, the output shaft 4 and the transmission shaft 9 are arranged horizontally, the transmission shaft 9 is provided with a sprocket 8, and the transmission connection on the sprocket 8 is vertically arranged chain 5, the output shaft 4 is welded with sprockets matched with the chain 5, and the output shaft 4 can a

Embodiment 2

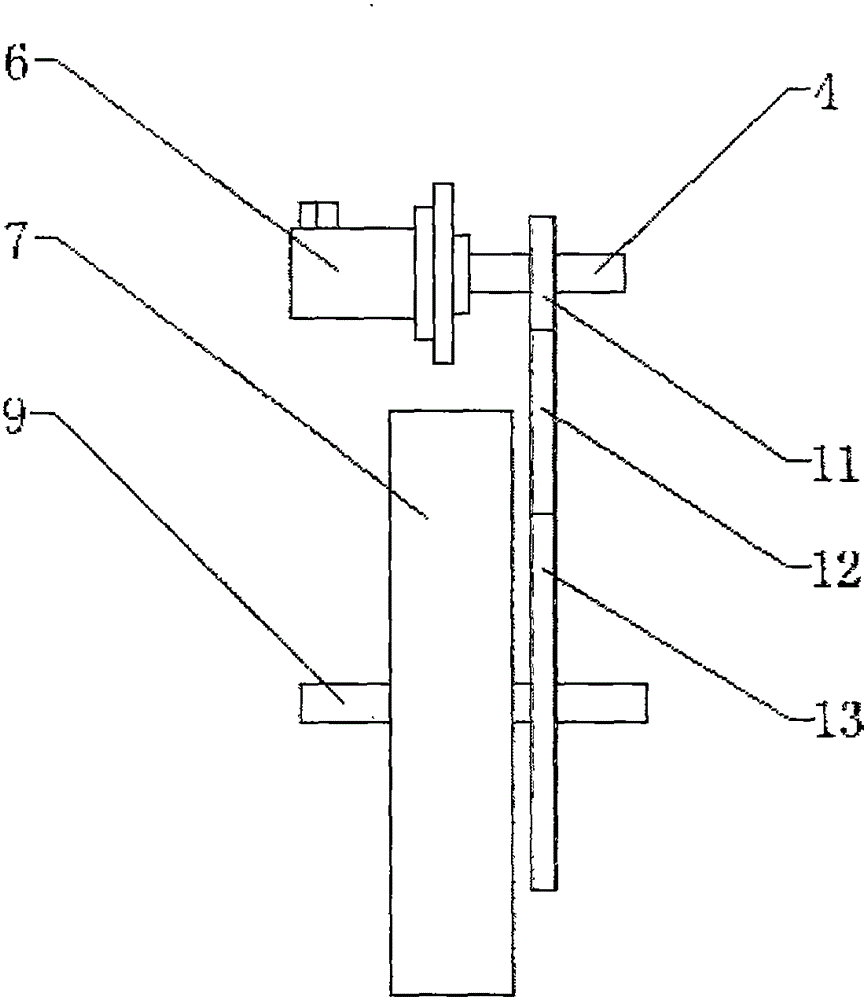

[0021] Embodiment 2: as figure 1 and figure 2 As shown, a plant protection machine is provided with a first gear 11 on the output shaft 4 , and a second gear 13 is provided on the transmission shaft 9 , and the first gear 11 and the second gear 13 are connected through an intermediate gear 12 . Of course, the number of intermediate gears 12 can be one or more.

[0022] During use, hydraulic motor 6 transmits power to road wheel 7 through gears, and all the other contents are the same as embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap