Self-propelled construction machine

a construction machine and self-propelled technology, applied in the direction of servomotors, ways, working accessories, etc., can solve the problems of ineffective counteraction, inability to effectively counteract, and inability to adjust the rotational speed of the travelling device only collectively, so as to improve the drive system of the travelling devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

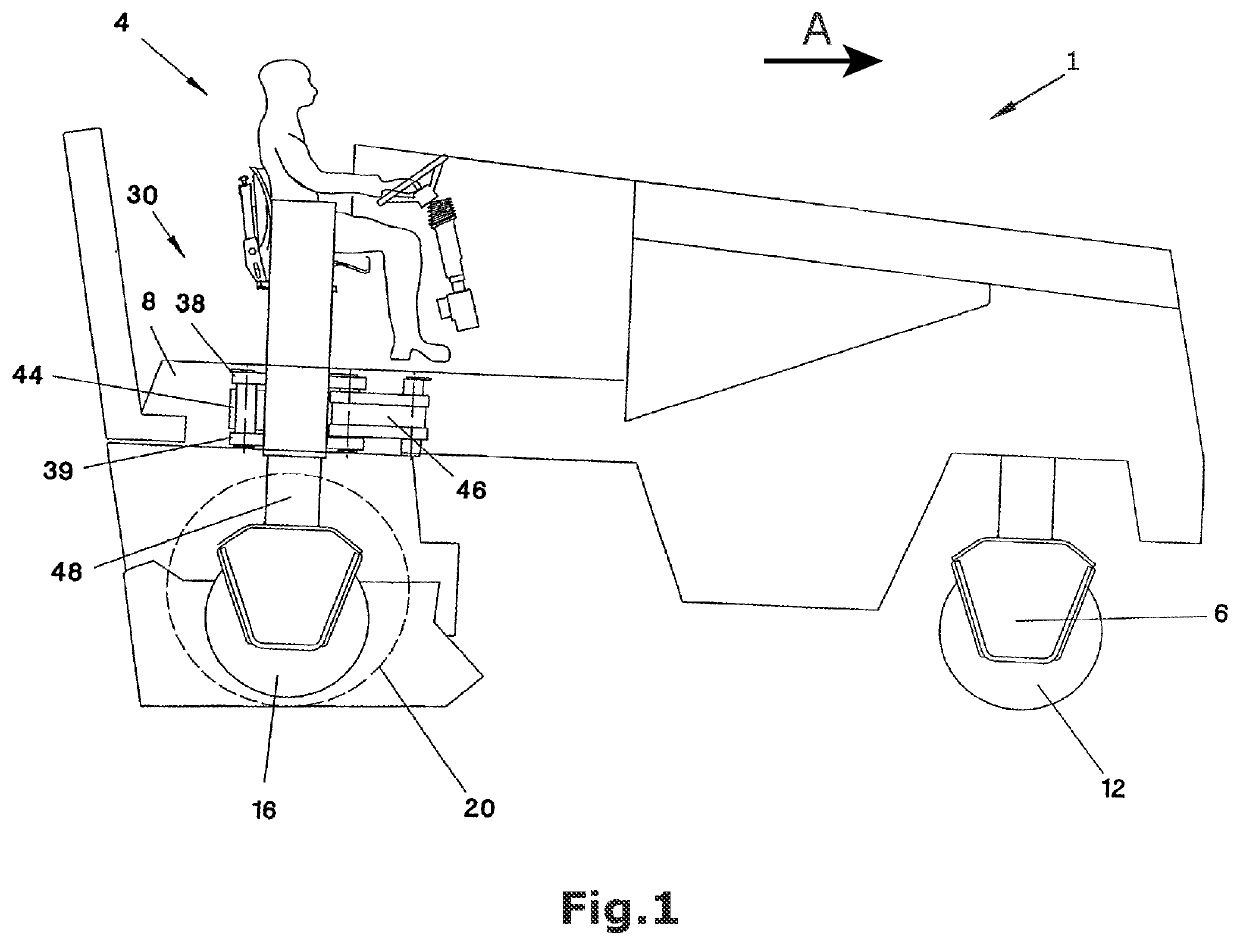

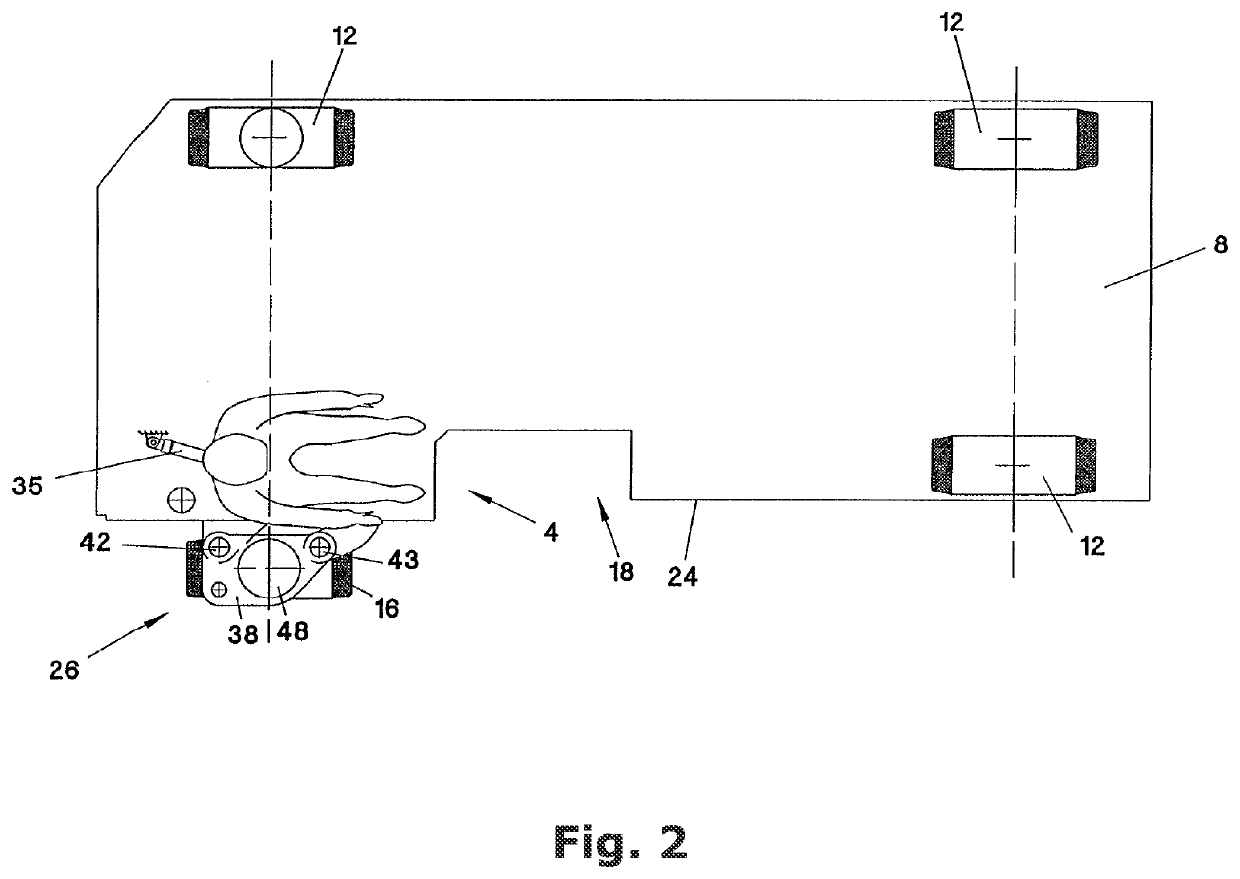

[0045]FIG. 1 shows a self-propelled construction machine 1. In the embodiment depicted, the self-propelled construction machine is a road milling machine. Said construction machine 1 comprises a machine frame 8 and at least three travelling devices 12, 16. The construction machine 1 depicted comprises two front 12 and two rear 12, 16 travelling devices, of which, in FIG. 1, the ground-engaging units arranged on the left side as seen in the direction of operation A are not visible. The travelling devices may be wheels, as in the embodiment depicted, or alternatively also tracked ground-engaging units.

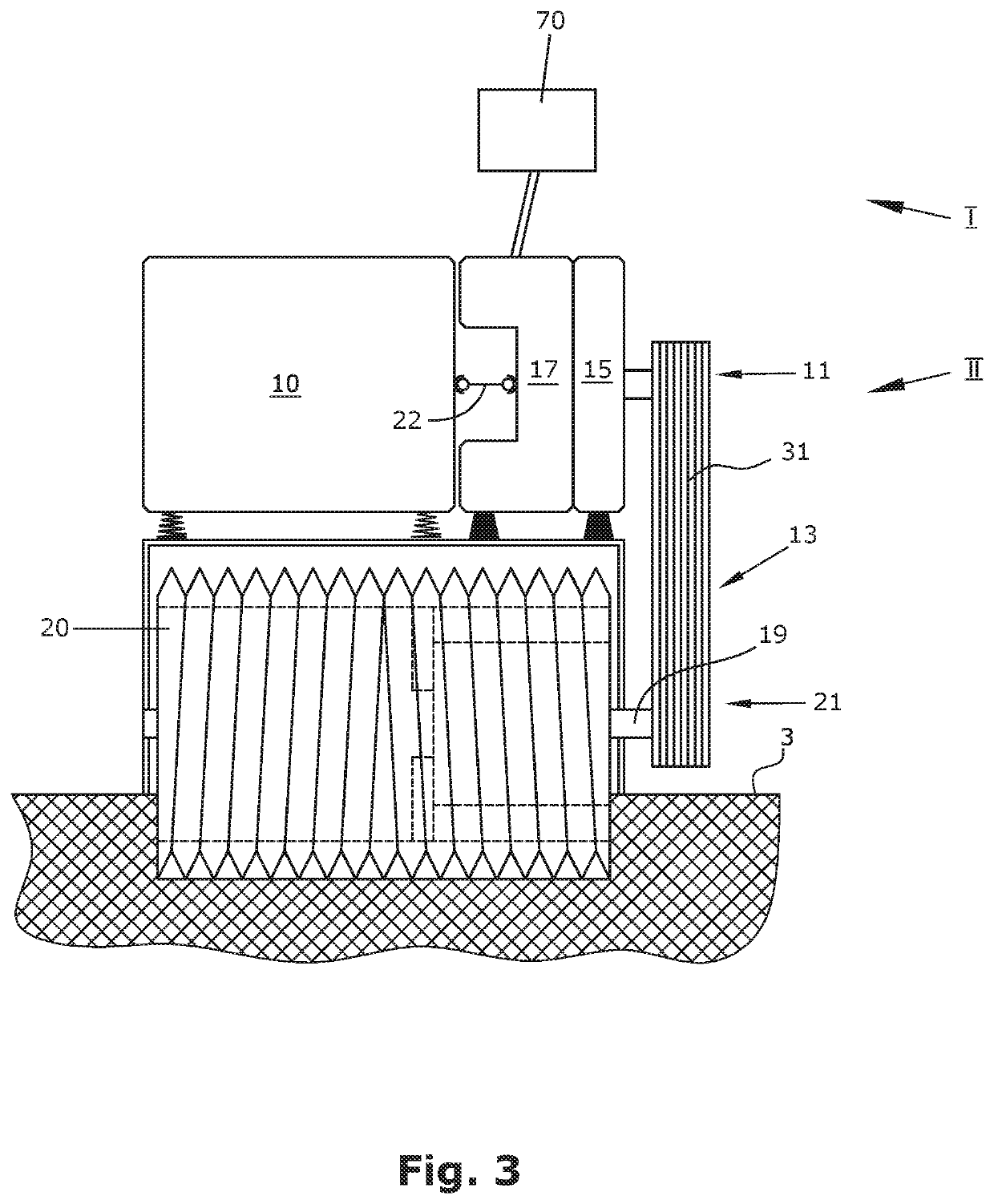

[0046]The travelling devices 12, 16 may each be driven by means of at least one hydraulic drive system 70. In a construction machine 1, at least two travelling devices may be driven, wherein, for example, the front travelling devices 12 may also be non-driven. At least one of the at least three travelling devices 12, 16 is realized as a pivotable travelling device 16. Said travelling device

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Volumetric flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap