Novel hydraulic control system for combine harvester

A hydraulic control system and combine harvester technology, which is applied to harvesters, cutters, mechanical equipment, etc., can solve problems such as large differences in flow requirements, easy damage to hydraulic pumps and pipelines, and inability to meet flow requirements at the same time. Good controllability and rapid flow change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

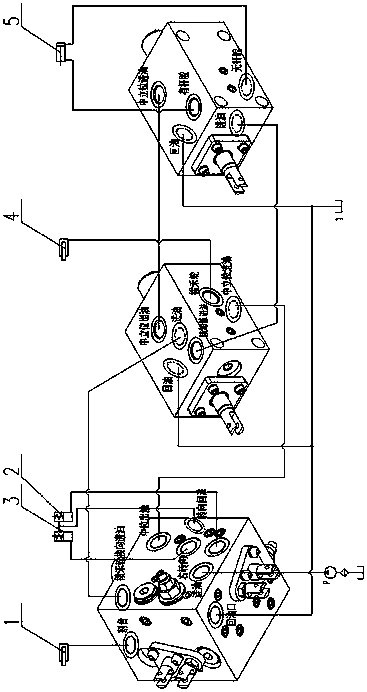

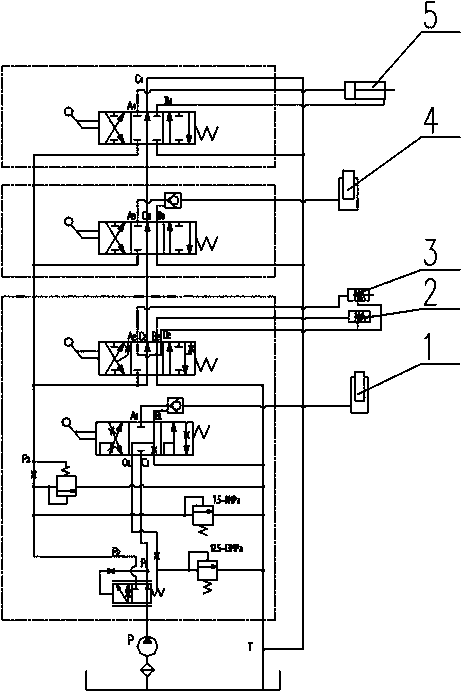

[0032] Embodiment: a kind of novel combine harvester hydraulic control system of this example, as figure 1 , figure 2 , consisting of two-way slide valve, single-way slide valve for reel, single-way slide valve for grain unloading, characterized in that the two-way slide valve is connected with header cylinder 1 and left steering cylinder 2 through pipelines , Right steering cylinder 3, the reel single-way slide valve is connected to the grain reel cylinder 4 through the pipeline, the grain unloading single-way slide valve is connected to the grain unloading cylinder 5 through the pipeline, the double-way slide valve, and the reel single-way The oil return ports of the slide valve and the grain unloading single-way slide valve are connected in parallel.

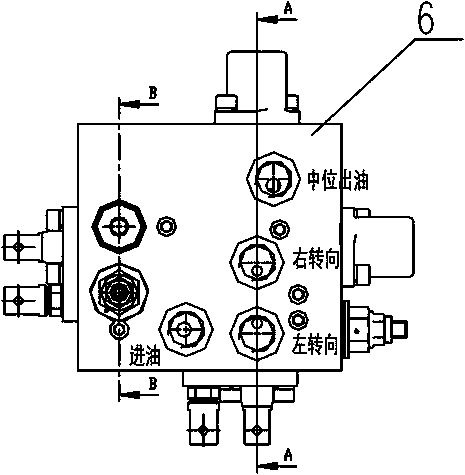

[0033] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , the double-way spool valve includes a double-way spool valve body 6, and a double-way spool valve plunger 7, a header valve stem 8, a pressure comp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap