Self-locking pressure signal feedback device

A pressure signal and feedback device technology, used in fire rescue and other directions, can solve the problems of no self-locking function, unable to confirm the fire extinguishing agent in the protection area in time, and achieve the effect of compact structure, convenient and fast installation, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

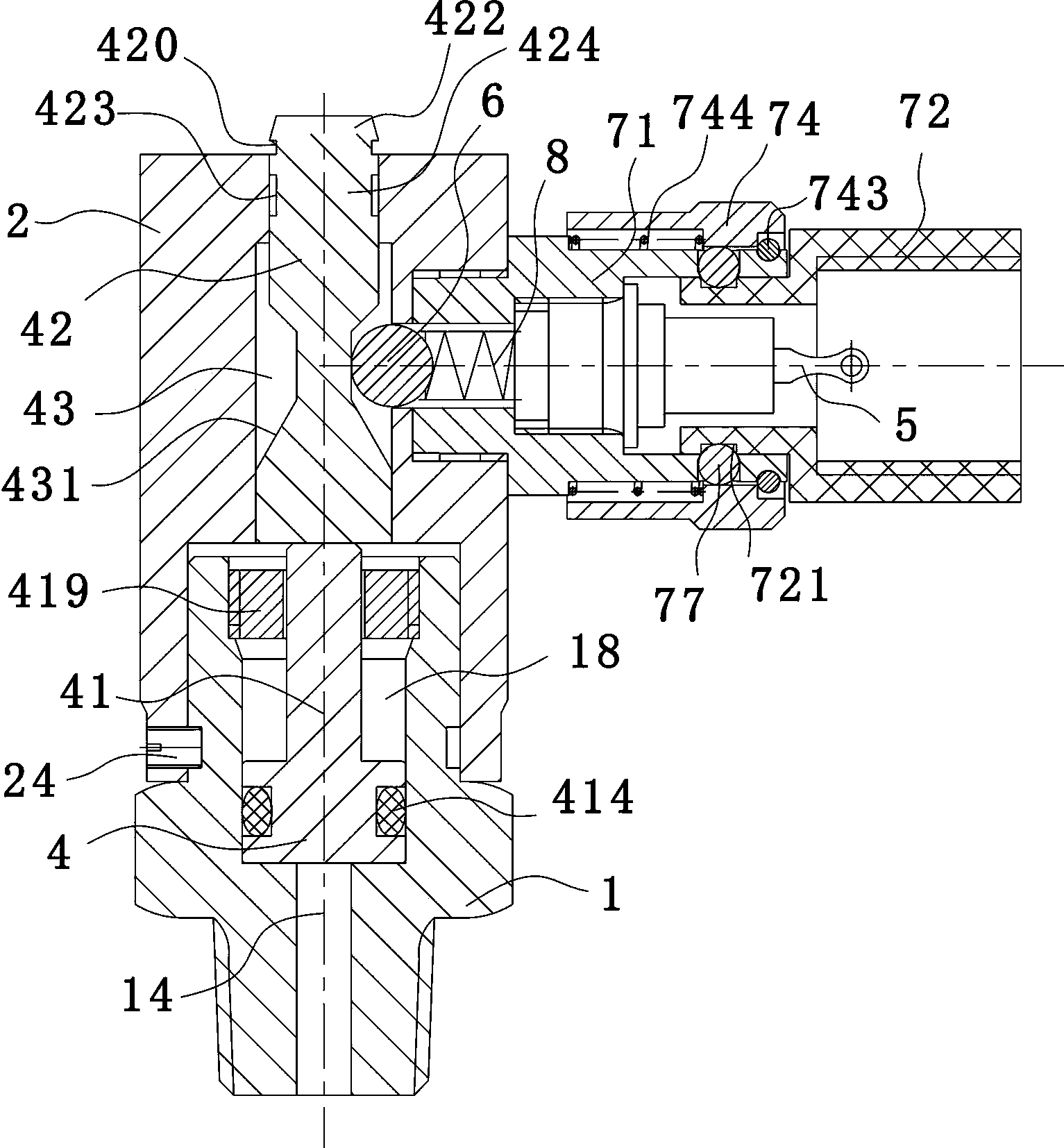

[0017] Such as figure 1 As shown, a self-locking pressure signal feedback device includes a valve body 1, a valve cover 2, a piston 4 and a micro switch 5. The valve cover 2 is covered outside the upper end of the valve body. Specifically, the valve body and the valve The caps are rotatably connected, that is, the valve cap can be rotated 360 degrees to facilitate the adjustment of the outlet direction as required. The valve cap is provided with a limit screw 24 that can limit its tripping; the piston 4 is located in the valve body 1, the valve body 1 is provided with a channel 14 for gas circulation and a chamber 18 for the piston 4 to move up and down. The chamber 18 and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap