Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Adsorption effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polyacrylonitrile-based hollow carbon fibers

InactiveCN109576824AMake up for the vacancyEfficient use ofWet spinning methodsConjugated synthetic polymer artificial filamentsCarbon fibersCarbonization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Binchotan-added activated carbon filter material for air conditioners and preparation method thereof

InactiveCN104324699AGood health effectImprove adsorption efficiencyOther chemical processesFiltration separationIonActivated carbon

The invention discloses a Binchotan-added activated carbon filter material for air conditioners. The Binchotan-added activated carbon filter material is characterized by being prepared from the following raw materials, by weight, 135-145 parts of cocoanut active charcoal, 10-15 parts of Binchotan, 2-3 parts of potassium hydroxide, 3-4 parts of brown sugar, 12-14 parts of zeolite powder, 7-9 parts of meerschaum powder, 3-5 parts of seaweed meal, 1-2 parts of sodium alginate, 1-2 parts of D-sodium erythorbate, 4-6 parts of sodium chloride, 4-6 parts of an adsorbent-aid and a proper amount of water. Apart from the addition of components such as zeolite powder, meerschaum powder and the like that enhance the adsorbing effect, the component Binchotan is also added, enhancing adsorptivity of activated carbon, releasing negative ions, blocking electromagnetic wave and appropriately adjusting indoor humidity. The component Binchotan has an excellent health-care effect. In cooperation of the adsorbent-aid, adsorption efficiency is enhanced, and indoor harmful gases are removed rapidly to make the air indoors fresh and pleasant. The preparation process is simple, and the activated carbon filter material has long service life and can repeatedly be used.

Owner:MINGGUANG JIAYI ELECTRIC CONTROL TECH

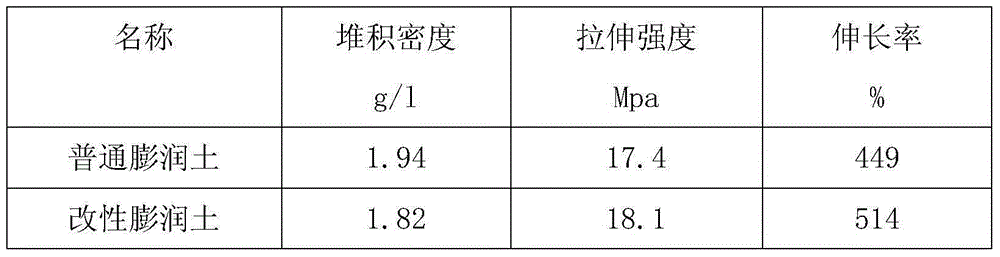

Porous modified bentonite with foaming effect and preparation method thereof

InactiveCN105126779APorousReasonable formulaOther chemical processesAlkali metal oxides/hydroxidesPorositySodium Bentonite

Owner:安徽雪城超细碳酸钙有限公司

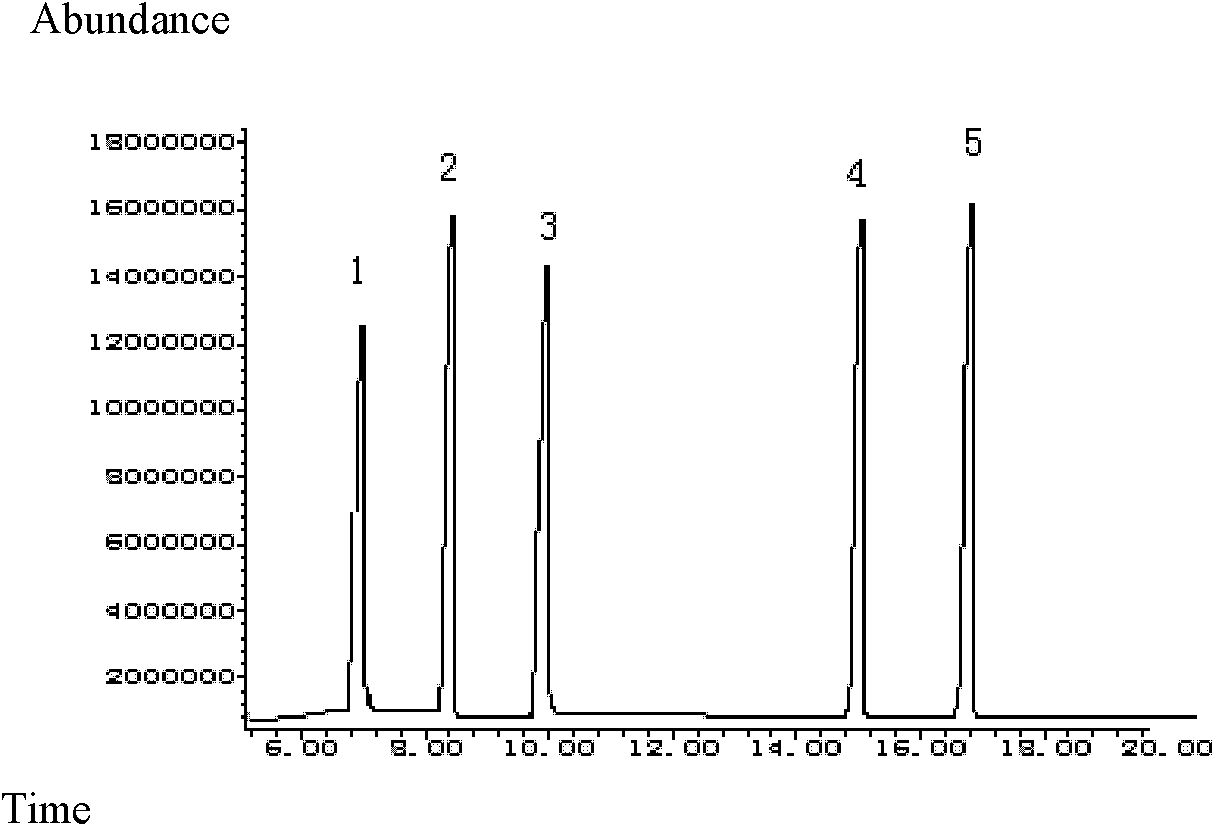

Method for estimating in-vitro detoxification effect of mycotoxin detoxification agent by using liquid chromatography

InactiveCN105301134AApplicable adsorption rate evaluationThe evaluation results are close toComponent separationMycotoxinSorbent

Owner:江苏奥迈生物科技有限公司

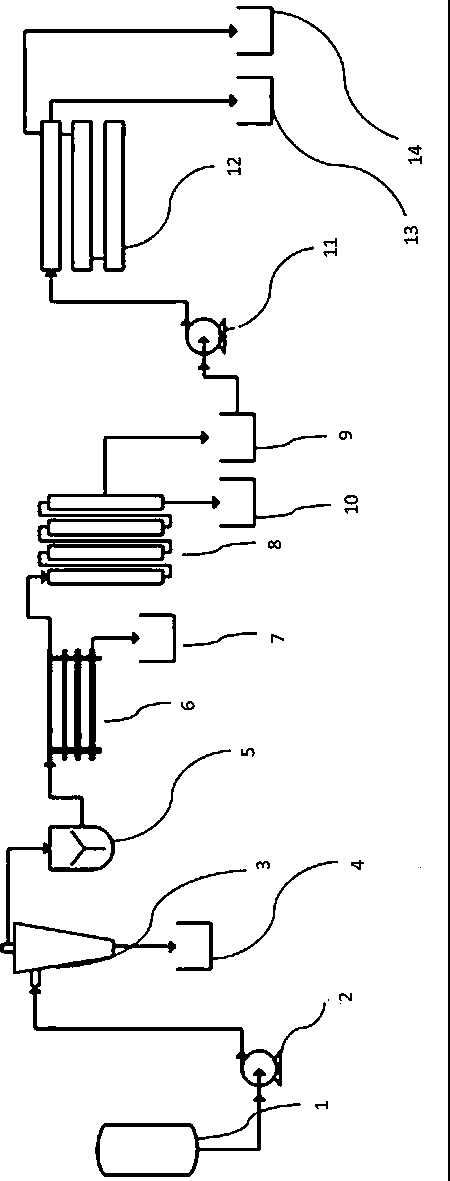

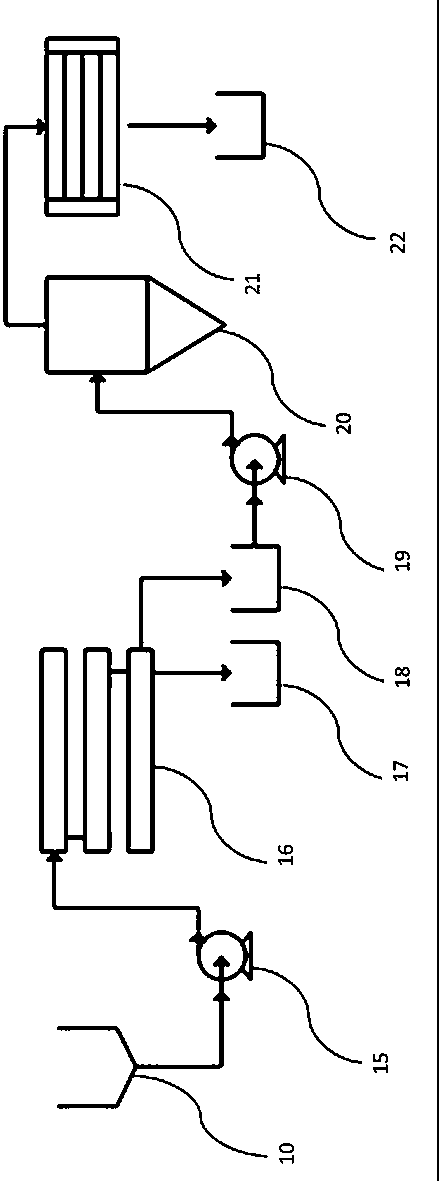

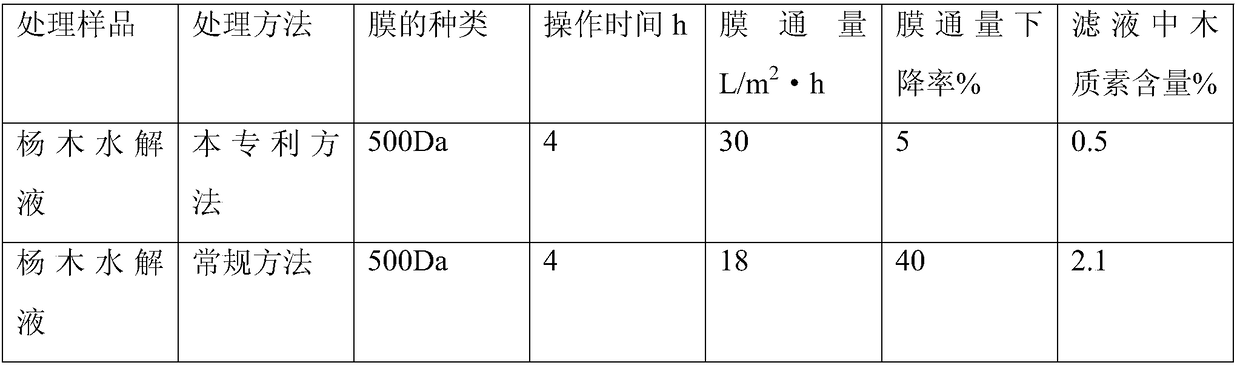

Method for refining high-temperature wood hydrolyzate

Owner:CHENGDU LIANJIE MEMBRANE TECH

Efficient nitrogen and phosphorus removal granular preparation and production process thereof

InactiveCN107055649AEasy to makeReduce energy consumptionWater treatment parameter controlWater contaminantsDodecyl sulfatePotassium ferrate

The invention relates to an efficient nitrogen and phosphorus removal granular preparation. The granular preparation is prepared from raw materials in parts by weight as follows: 20-100 parts of potassium ferrate, 20-100 parts of bentonite, 1-5 parts of disodium EDTA, 10-50 parts of cement and 1-5 parts of a sodium lauryl sulfate aqueous solution. The concentration of the sodium lauryl sulfate aqueous solution is 2-3 g / L. The production technology of the efficient nitrogen and phosphorus removal granular preparation comprises the steps as follows: (1) potassium ferrate, bentonite, disodium EDTA and cement are mixed and stirred uniformly in proportion, a mixture is obtained; (2) the sodium lauryl sulfate aqueous solution is added to the mixture in step (1) and mixed and stirred uniformly, granulation and drying are performed, and the granular preparation is obtained. The efficient nitrogen and phosphorus removal granular preparation and the production process thereof have the benefits that energy consumption is low in the preparation process of nitrogen and phosphorus removal granular preparation, preparation is simple, no secondary pollution is caused to the environment, and the heavy metal adsorption effect is good.

Owner:YIKANG TECH CO LTD

Preparation method of filtering material for adsorbing fluorine ions in water

InactiveCN109929082AFully contactedGood chemical stabilityWater contaminantsWater/sewage treatment by flocculation/precipitationSorbentDiethylenetriamine

Owner:宁波市河清源技术转移服务有限公司

Stirring and extracting bar for polyacrylate compound nanocarbon fiber coating and its preparation method

InactiveCN102366719AAvoid competitive adsorptionHigh enrichment factorIon-exchange process apparatusOther chemical processesCarbon fibersAdsorption effect

Owner:TIANJIN CHUNFA BIO TECH GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap