Method for refining high-temperature wood hydrolyzate

A refining method and hydrolyzate technology are applied in the refining field of high-temperature wood hydrolyzate, which can solve the problems of complex process, low efficiency, toxic and side effects, and achieve the effects of improving processing efficiency, short material time, and short material residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

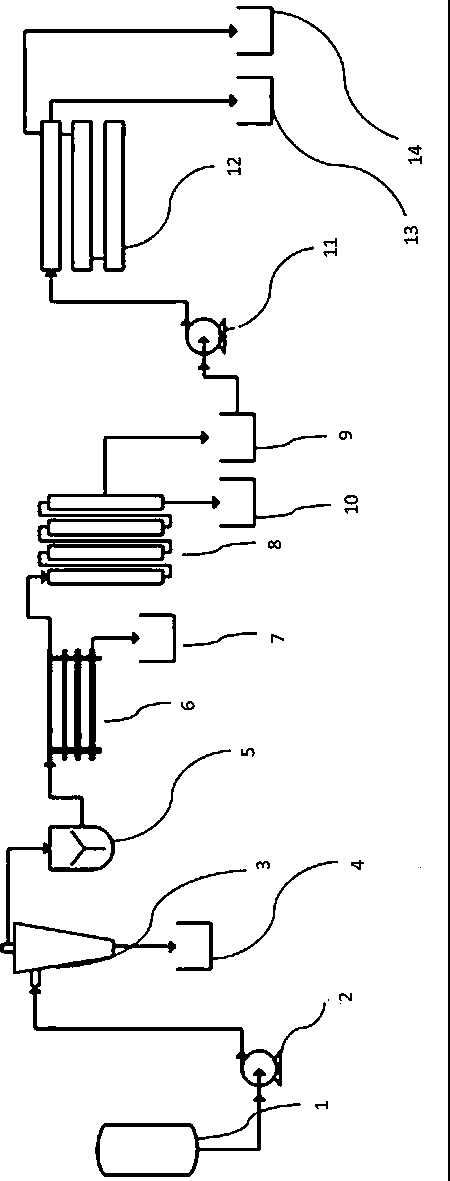

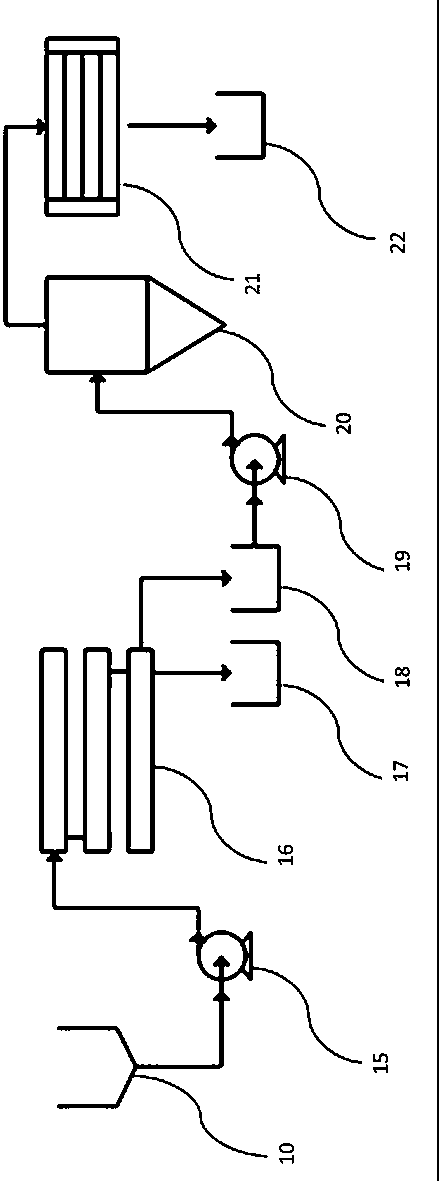

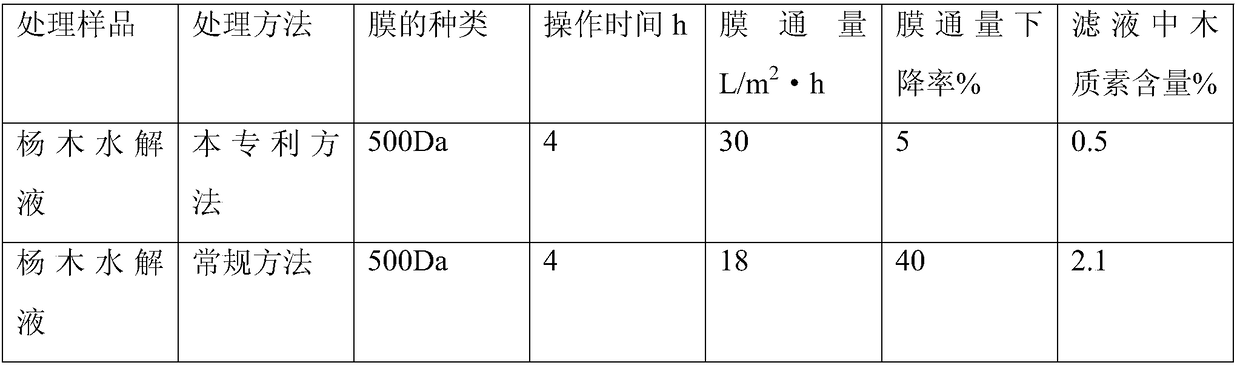

[0030] The purpose of the present invention is to provide a process for removing most of lignin from wood high temperature hydrolyzate. The soluble lignin macromolecules in the prehydrolyzate have colloidal characteristics, which can easily cause membrane clogging in the subsequent treatment. Therefore, some embodiments of the present disclosure include a hydrocyclone to remove large particles of impurities. The hydrocyclone is a device that uses centrifugal force to separate two media with different gravity. The hydrolyzate contains some insoluble Particles from the water, thereby separating them out. Lignin contains a large number of active groups such as hydroxyl and carboxyl, with negative charges. The flocculant used in the present invention can chemically react with lignin to form lignin complex, and the solubility of lignin changes to precipitate. The flocculant adsorbs lignin to form a colloid to flocculate, or changes the spatial structure of lignin to precipitate lign

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap