Mini Receptacle

a technology of conductive terminals and receptacles, applied in the direction of coupling device connections, coupling protective earth/shielding arrangements, electric discharge lamps, etc., can solve the problems of short circuit failure, conductive terminal portions are still prone to contact, short circuit may occur, etc., and achieve the effect of preventing short circuit failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

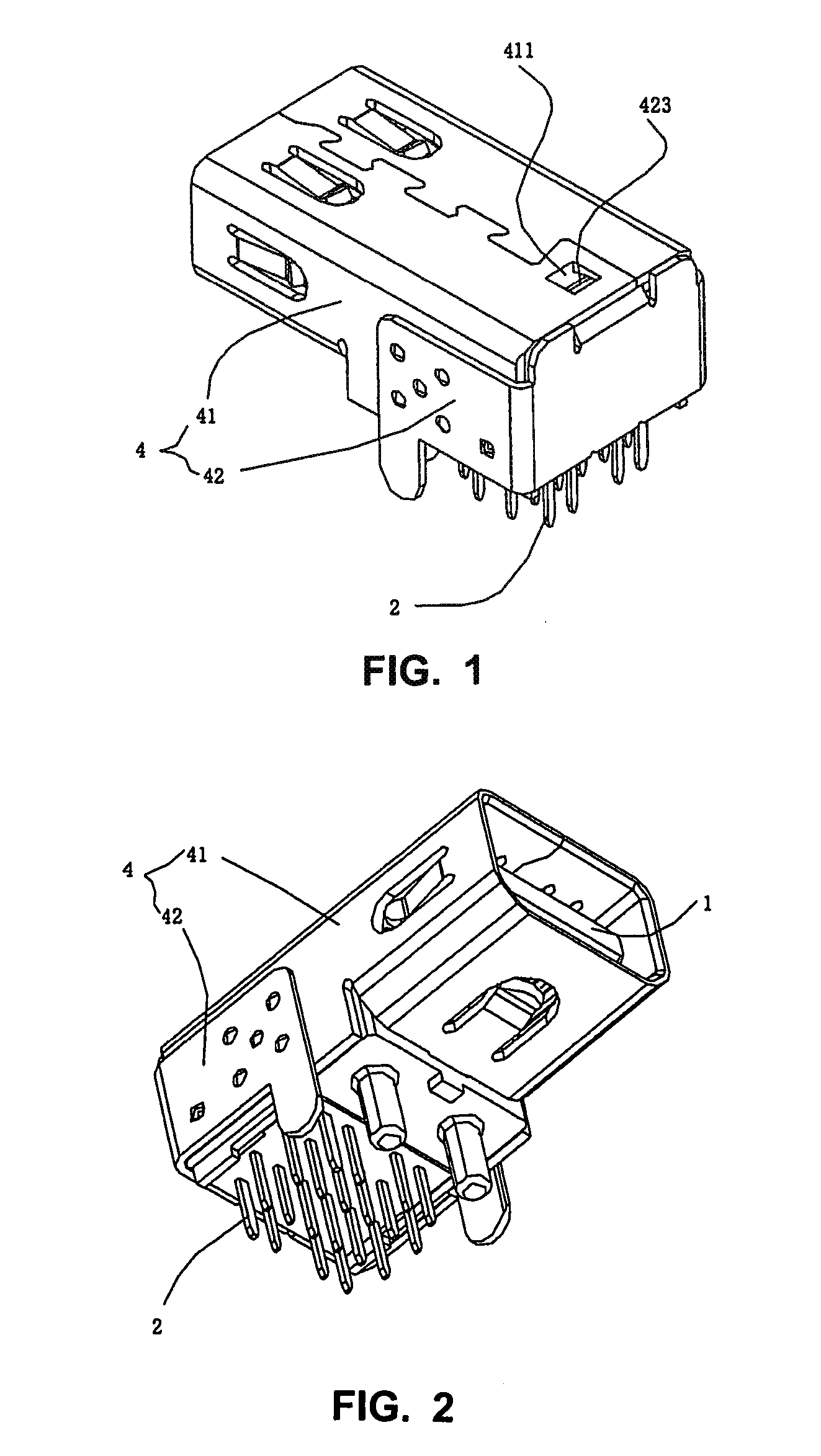

[0024]The present invention will be described in detail with reference to the drawings, by taking the Mini-Displayport electrical connector as an example.

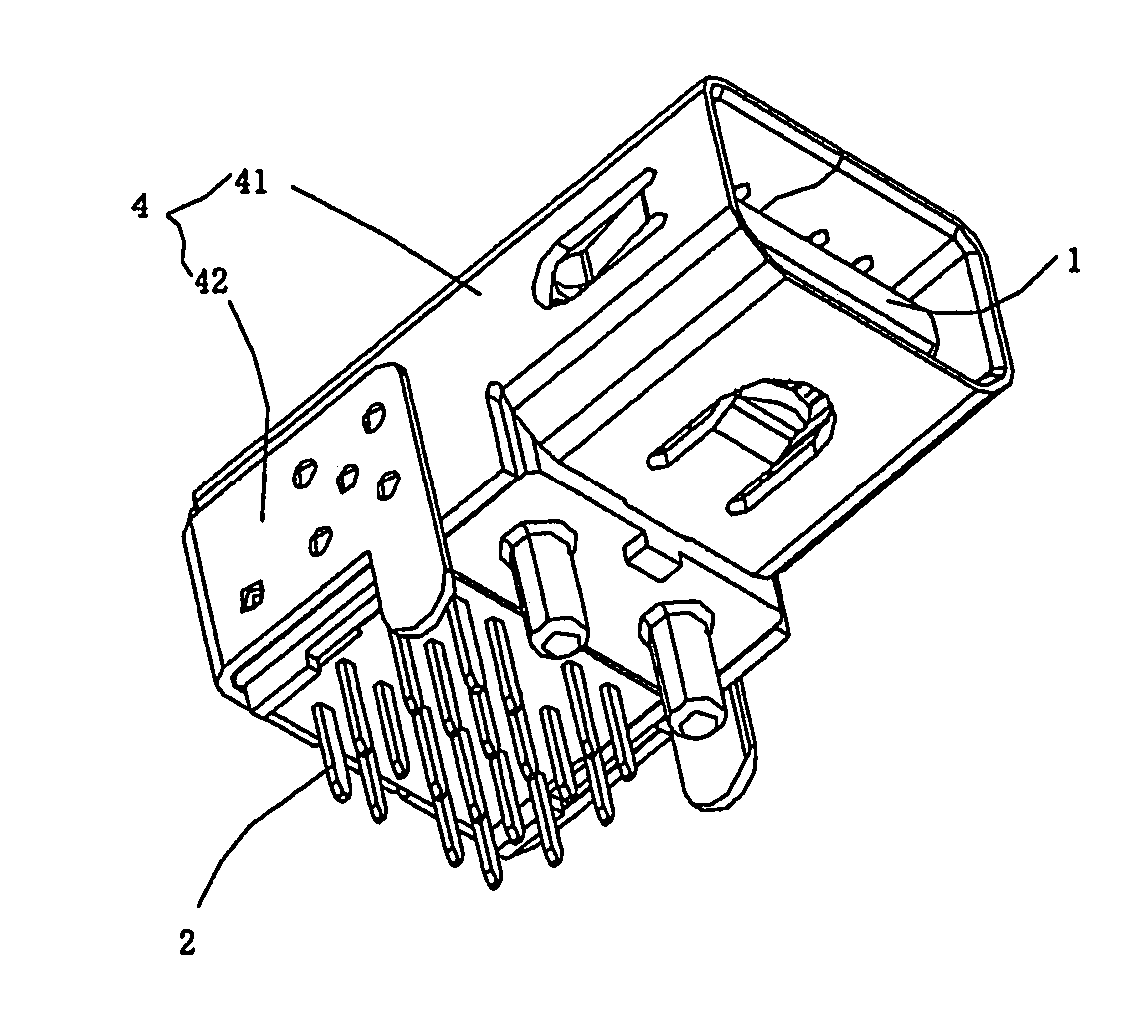

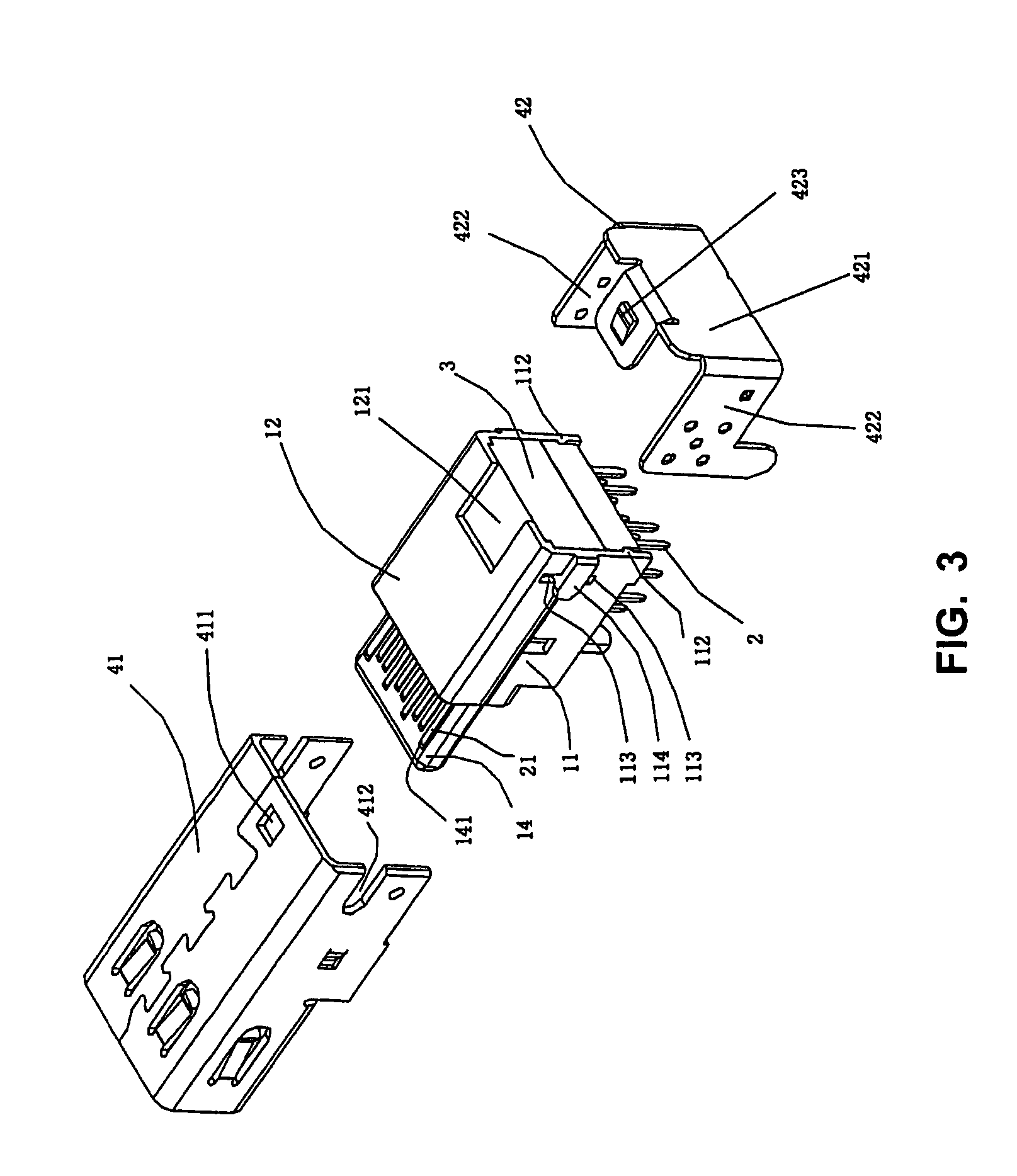

[0025]As shown in FIGS. 1 to 4, an electrical connector according to a preferred embodiment of the present invention comprises an insulating housing 1, a plurality of conductive terminals 2 fitted on the insulating housing 1, a positioning module 3 for fixing the plurality of conductive terminals 2, a spacer plate 34, and a shielding casing 4.

[0026]Referring to FIGS. 5 and 6, an accommodating chamber 13 is provided at the rear portion of the insulating housing, which is formed by two sidewalls 11 and a top wall 12, and a tongue plate 14 is protruded forwards from the front portion of the insulating housing 1. A plurality of terminal receiving grooves 141 are provided at both of the upper and lower sides of the tongue plate 14, which penetrate through the insulating housing 1 from front to rear. Both of the inner surfaces of two sidewa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap