Filter pressing unit and filter press

A filter unit and guide sleeve technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of lateral deformation of springs, tilting of filter presses, unbalanced force, etc. Achieve the effect of improving verticality and parallelism, ensuring axial force and verticality, and improving parallelism and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

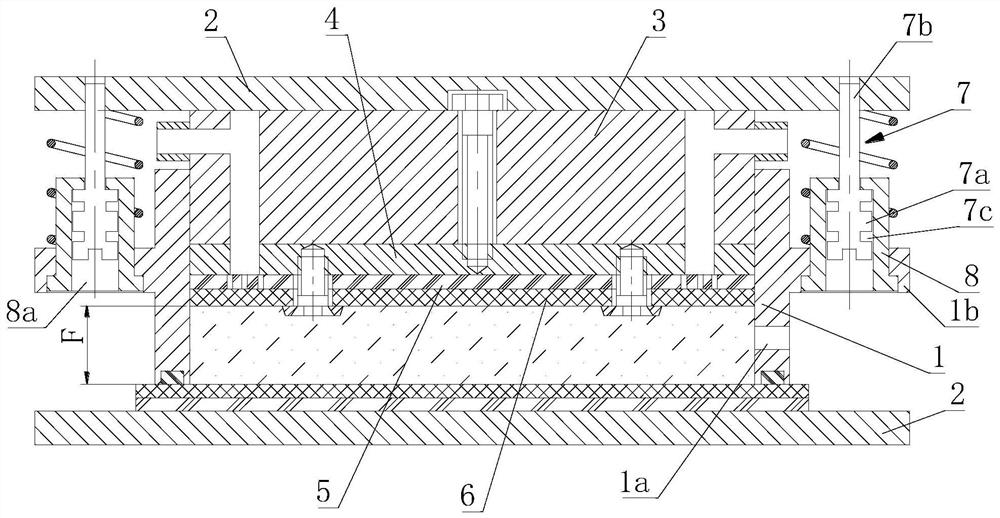

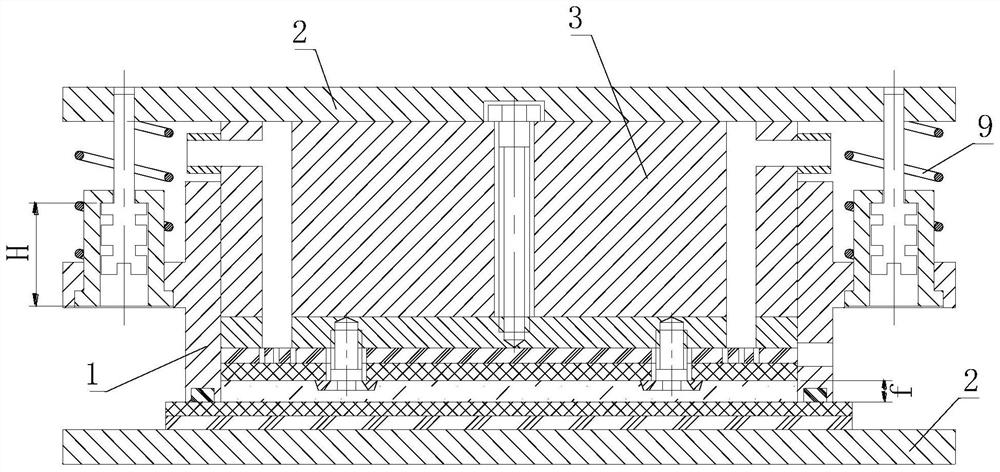

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings. When describing the embodiments of the present invention in detail, for the convenience of explanation, the accompanying drawings showing the structure of the device will not be partially enlarged according to the general scale, and the schematic diagram is only an example, and it should not be limited here. The protection scope of the present invention. It should be noted that the drawings are in simplified form and use inaccurate scales, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0024] The filter press mainly includes a frame, a filter cylinder, a pressure plate and a filter plate (filter cloth, filter screen), among which the piston (also called a pressure plate), the filter plate assembly and the filter cylinder constitute the filter unit of the filter press. . The multi-layer filter p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap