Treatment method of carbon felt for vanadium batteries

A treatment method and technology for vanadium batteries, applied in the field of vanadium batteries, can solve the problems of limited improvement in electrochemical activity and long activation time, and achieve the effects of good activation effect of carbon felt, good activation effect and short treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

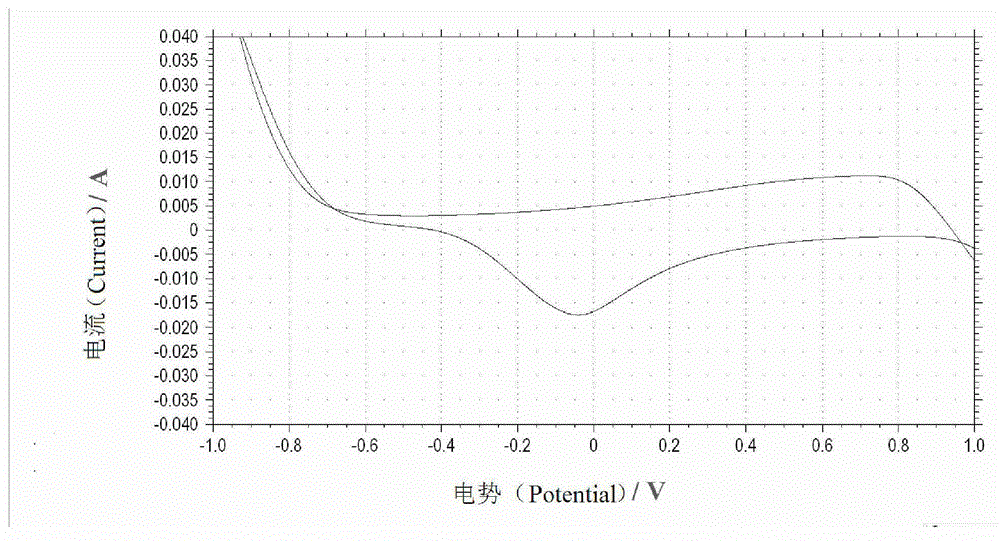

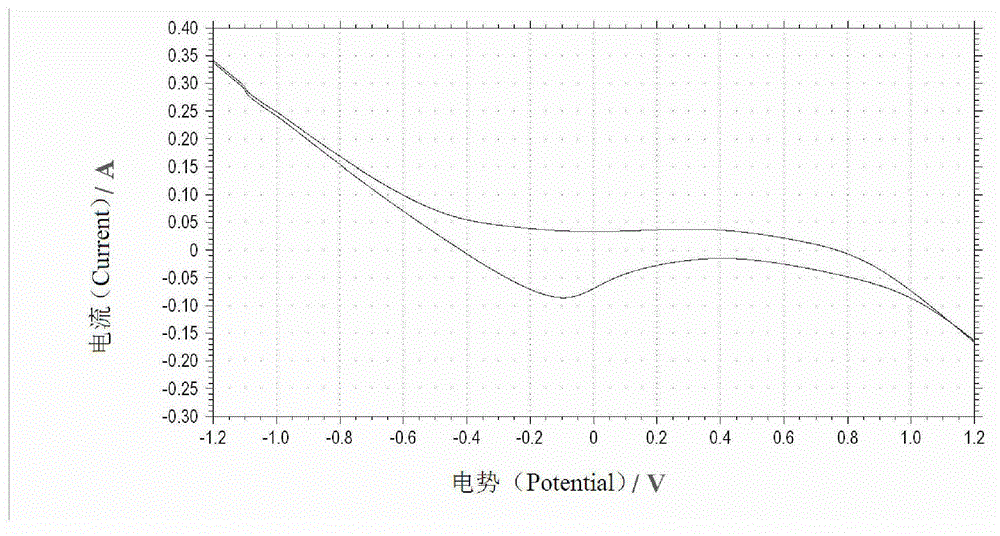

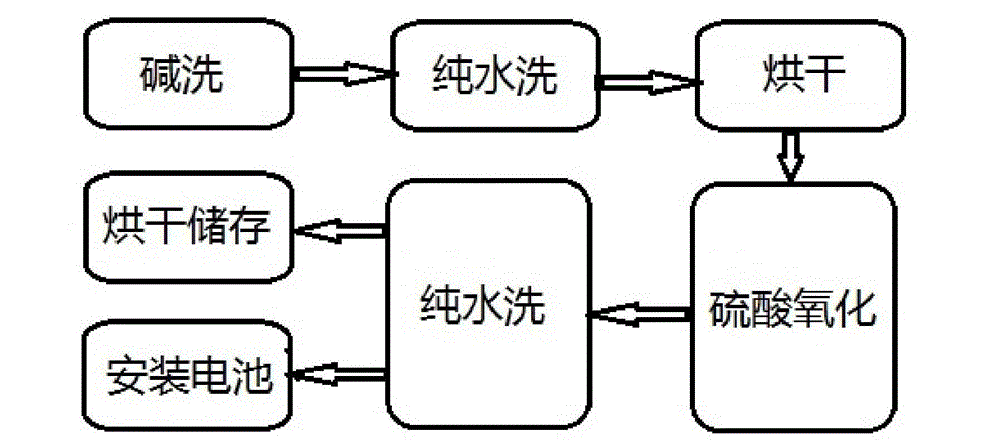

Embodiment 1

[0038] Dip the polyacrylonitrile-based carbon felt after carbonization treatment at 1100~1300°C in 3mol / L NaOH solution at 50°C for 30 minutes to remove the hydrophobic oils and fats attached to the carbon felt, then take it out and put in an appropriate amount of pure Rinse in water, take it out and dry it in an oven at a constant temperature of 40°C. Put the dried and dehydrated carbon felt into 98% sulfuric acid at 60°C for oxidative activation for 4.0 hours to increase the oxygen-containing groups on the molecular structure of the carbon felt, improve its hydrophilicity and the ability to adsorb electrochemically active ions, and then Remove from sulfuric acid and wash with pure water. The cleaned carbon felt can be directly loaded into the vanadium battery stack, or placed in an oven at a constant temperature of 40°C to dry and packaged for storage.

Embodiment 2

[0040] Dip the polyacrylonitrile-based carbon felt after carbonization treatment at 1100~1300°C in 1mol / L NaOH solution at 100°C for 10 minutes to remove the hydrophobic oils and fats attached to the carbon felt, then take it out and put it in an appropriate amount of pure Rinse in water, take it out and dry it in an oven at a constant temperature of 60°C. Put the carbon felt that has been dried to remove moisture into 70% sulfuric acid at 100°C for oxidative activation for 0.5 hours to increase the oxygen-containing groups on the molecular structure of the carbon felt, improve its hydrophilicity and the ability to absorb electrochemically active ions, and then Remove from sulfuric acid and wash with pure water. The cleaned carbon felt can be directly loaded into the vanadium battery stack, or placed in an oven at a constant temperature of 60°C to dry and packaged for storage.

Embodiment 3

[0042] Soak the polyacrylonitrile-based carbon felt after carbonization treatment at 1100~1300°C in 2mol / L NaOH solution at 80°C for 20 minutes to remove the hydrophobic oils and fats attached to the carbon felt, then take it out and put in an appropriate amount of pure Rinse in water, take it out and dry it in an oven at a constant temperature of 50°C. Put the dried and dehydrated carbon felt in 90% sulfuric acid at 80°C for oxidative activation for 2.5 hours to increase the oxygen-containing groups on the molecular structure of the carbon felt, improve its hydrophilicity and the ability to absorb electrochemically active ions, and then Remove from sulfuric acid and wash with pure water. The cleaned carbon felt can be directly loaded into the vanadium battery stack, or placed in an oven at a constant temperature of 50°C to dry and packaged for storage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap