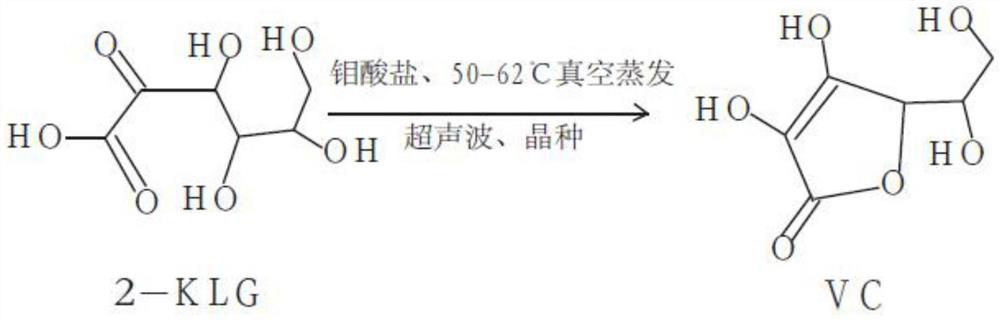

Method for preparing VC (Vitamin C) crystal in one step by using aqueous solution of 2-keto-L-gulonic acid

A technology of aqueous solution and gulonic acid, applied in the direction of organic chemistry, can solve problems such as endangering the health of production personnel, production environment pollution, production safety hazards, etc., and achieve the effects of saving treatment costs, reducing environmental pollution, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 200mL of 2-KLG saturated solution in a 1000mL three-necked flask, add 1‰ ammonium molybdate to the solution, shake to dissolve; Keep it at 22-25Kpa. Quickly put the flask into a 50°C constant temperature water tank with ultrasonic waves while shaking, so that the saturated 2-KLG aqueous solution is all below the hot water, and turn on the ultrasonic waves with a frequency of 20khz. It was observed that there was crystallization at the bottom of the flask. When the volume of the solution became 100mL, the reaction was stopped and filtered to obtain crystals, which were detected as VC. After subtracting 0.4g of VC seeds, the calculated yield was 78%. The ammonium molybdate remains in the solution and can be used as a catalyst after adding a new saturated solution of 2-KLG.

Embodiment 2

[0031] 200mL of 2-KLG saturated solution in a 1000mL three-neck flask, add 0.9‰ ammonium molybdate to the solution, shake to dissolve; Keep it at 25-26Kpa. Quickly put the flask into a 55°C constant-temperature water tank with ultrasonic waves while shaking, so that the saturated 2-KLG aqueous solution is all below the hot water, and turn on the ultrasonic waves with a frequency of 30khz. It was observed that there was crystallization at the bottom of the flask. When the volume of the solution became about 100mL, the reaction was stopped and filtered to obtain crystals, which were detected as VC. After subtracting 0.4g of VC seeds, the calculated yield was 74%.

Embodiment 3

[0033] 200mL of 2-KLG saturated solution in a 1000mL three-necked flask, add 0.9‰ ammonium molybdate to the solution, shake to dissolve; Keep it at 22-25Kpa. Put the flask into a 60°C constant-temperature water bath with ultrasonic waves while shaking, so that the saturated 2-KLG aqueous solution is all below the hot water, and turn on the ultrasonic waves with a frequency of 30khz. It was observed that crystals were produced at the bottom of the flask. When the volume of the solution became about 100 mL, the reaction was stopped and filtered to obtain crystals, which were detected as VC. After subtracting 0.2 g of VC seeds, the calculated yield was 70.1%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap