Cleaning device and cleaning method

A technology for cleaning devices and cleaning tanks, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve the problems of not being able to spray cleaning liquid and achieve a stable cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

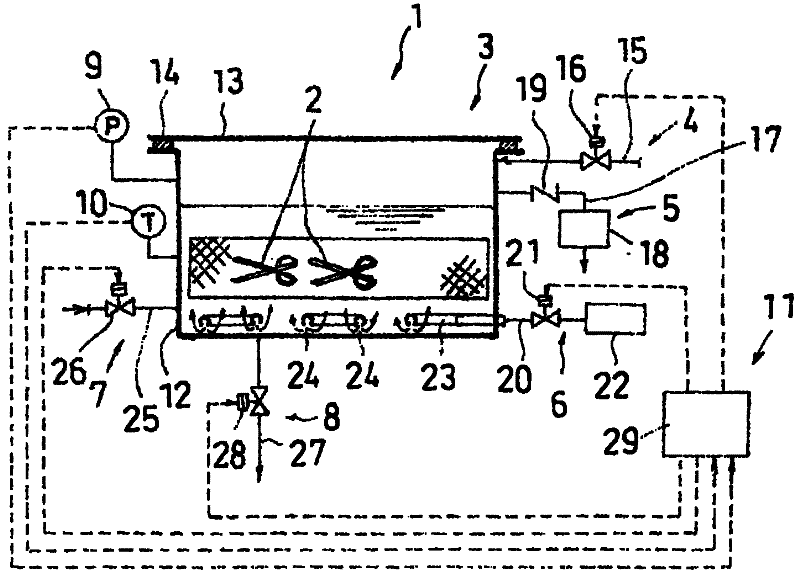

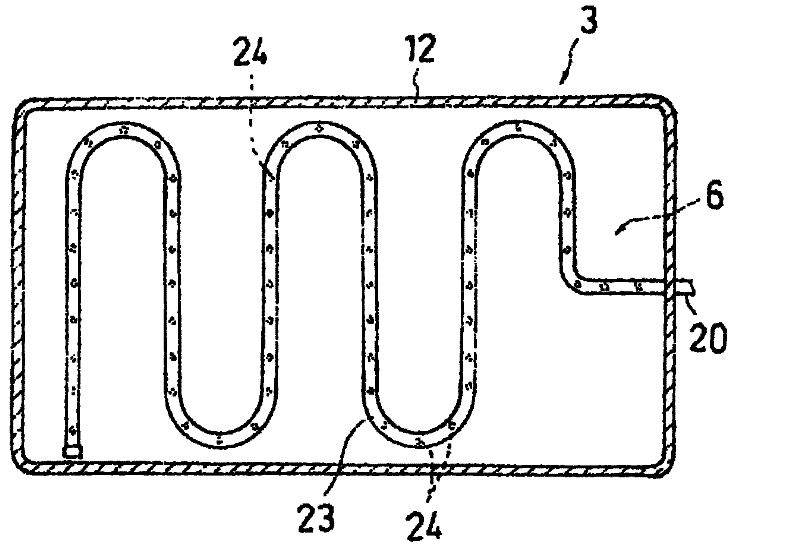

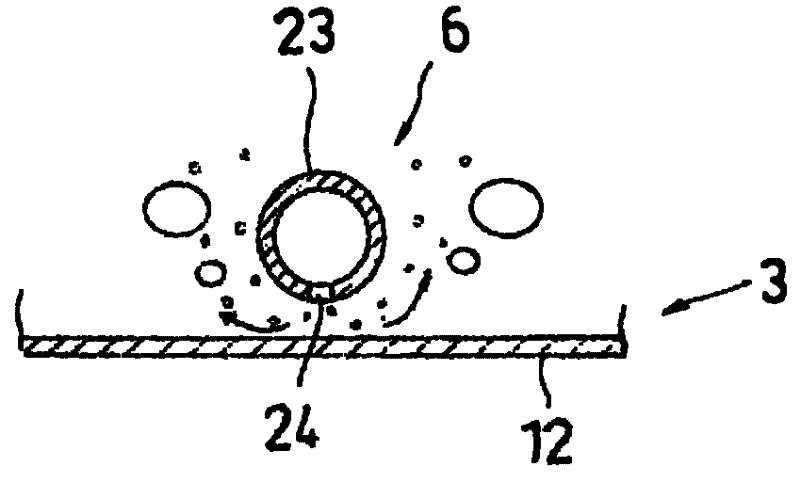

[0050] figure 1 It is a schematic configuration diagram showing Embodiment 1 of the cleaning device of the present invention, and a part thereof is shown in cross-section. in addition, figure 2 is a schematic cross-sectional view of a cleaning tank of the cleaning device. and then, image 3 yes figure 2 A schematic longitudinal sectional view of a part of , showing a state in which gas is introduced into the cleaning liquid.

[0051] The cleaning device 1 of the present embodiment is provided with: a cleaning tank 3, wherein the cleaning liquid is accumulated and the object to be cleaned 2 is immersed; a water supply mechanism 4, which supplies the cleaning liquid into the cleaning tank 3; The gas is sucked and discharged to the outside to reduce the pressure in the cleaning tank 3; the gas supply mechanism 6 is used to introduce gas into the cleaning solution in the cleaning tank 3; the heating mechanism 7 is used to heat the cleaning solution in the cleaning tank 3; Drai

Embodiment 2

[0083] Figure 5 It is a schematic configuration diagram showing Embodiment 2 of the cleaning device 1 of the present invention, and a part thereof is shown in cross-section. The cleaning device 1 of the second embodiment is basically the same as that of the first embodiment. Here, the following description will focus on the differences between the two, and the corresponding parts will be described with the same reference numerals.

[0084] The cleaning device 1 of the present embodiment 2 is equipped with: a cleaning tank 3, wherein the cleaning liquid is accumulated and the object 2 to be cleaned is immersed; a water supply mechanism 4, which supplies the cleaning liquid to the cleaning tank 3; The gas in the cleaning tank 3 is sucked and discharged to the outside to decompress the inside of the cleaning tank 3; the recompression mechanism 30 introduces external gas into the gas phase part of the decompressed cleaning tank 3 to restore the pressure in the cleaning tank 3 and r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap