Fireproof mineral silicone rubber composition, fireproof mineral silicone rubber material, preparation method thereof and power line containing fireproof mineral silicone rubber material

A silicone rubber composition, mineral technology, applied in the direction of rubber insulators, circuits, electrical components, etc., can solve the problems of poor fire resistance of air-conditioning power lines, etc., to achieve improved mixing and dispersion effects, stable structure, improved flexibility and fire resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

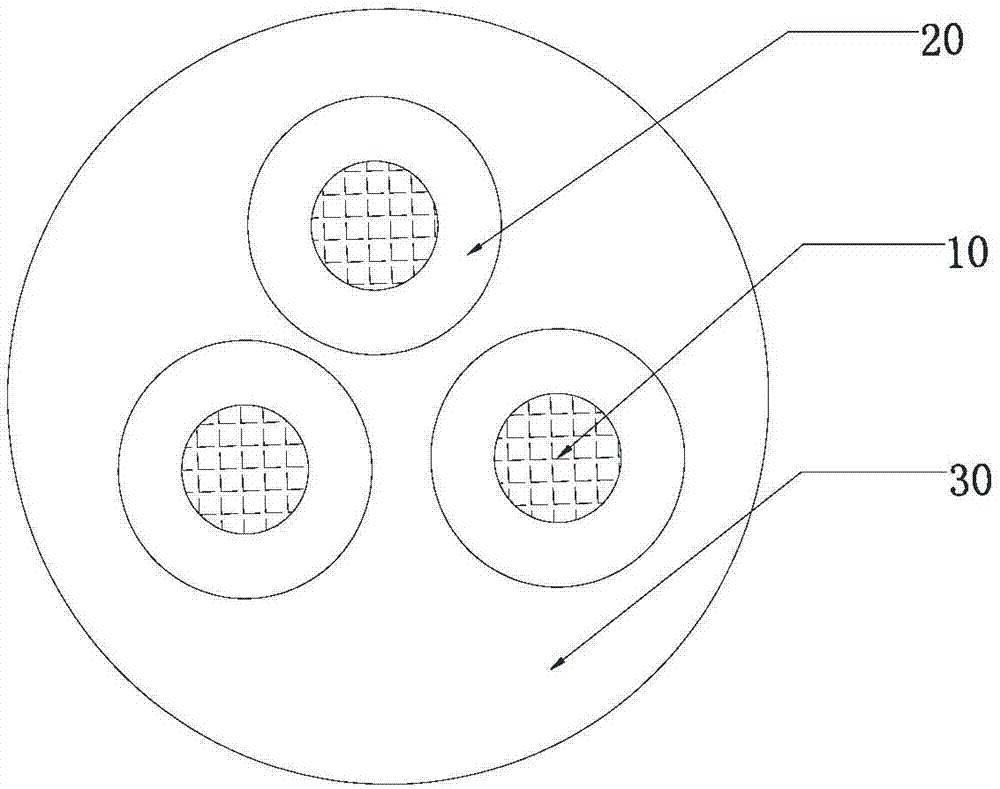

Image

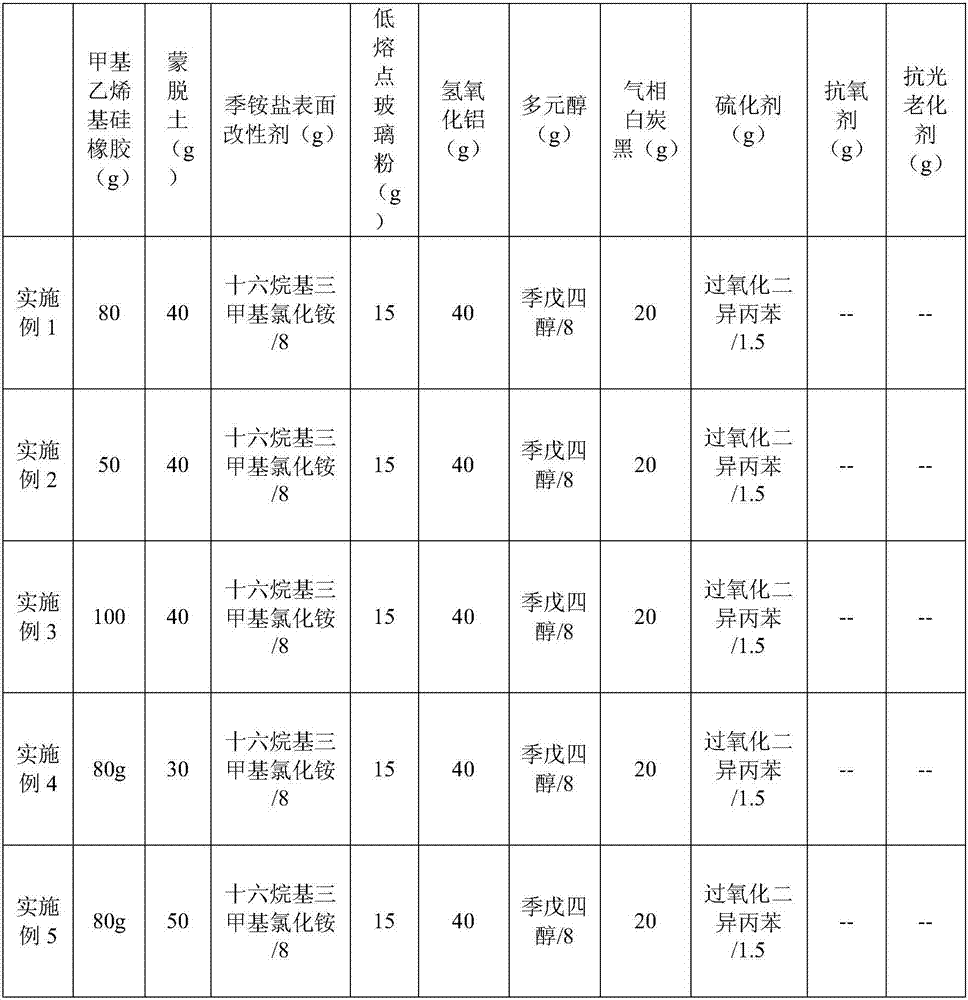

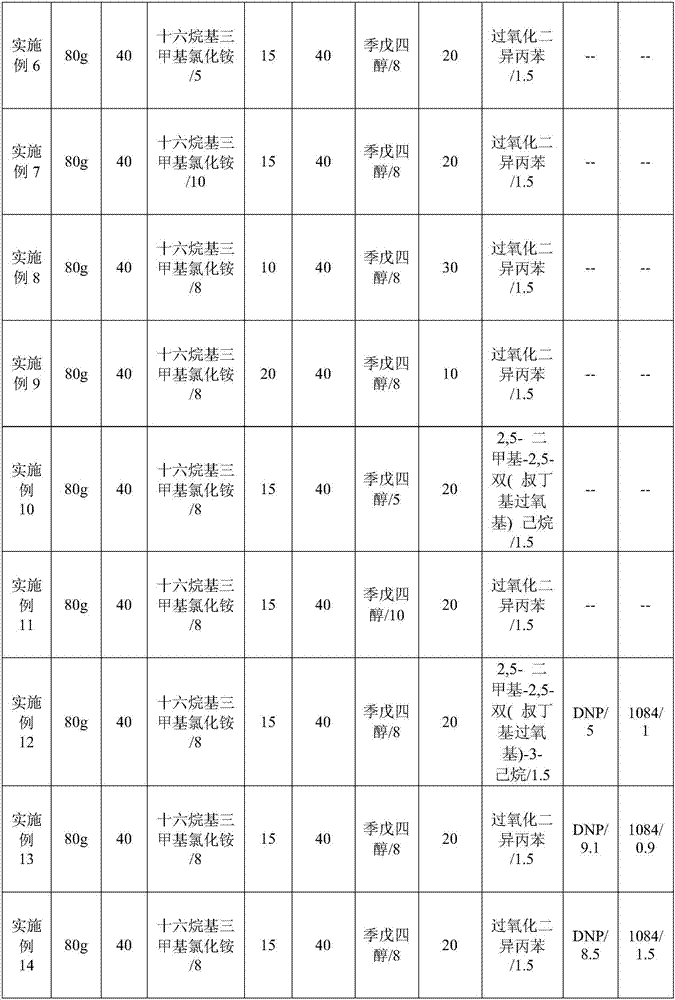

Examples

preparation example Construction

[0036] In yet another typical embodiment of the present application, a method for preparing a fire-resistant mineral silicone rubber material is provided. The preparation method uses any of the above-mentioned fire-resistant mineral silicone rubber compositions as a raw material, and includes the following steps: S1 , using quaternary ammonium salts to modify montmorillonite to obtain modified montmorillonite; S2, mixing methyl vinyl silicone rubber, modified montmorillonite, low-melting glass powder, aluminum hydroxide and polyols Plasticizing to obtain the fire-resistant mineral base material; and S3, granulating the fire-resistant mineral base material to obtain the fire-resistant mineral silicone rubber material.

[0037] Firstly, montmorillonite is modified with quaternary ammonium salt to obtain modified montmorillonite, so as to improve the mixing and dispersion effect of montmorillonite in methyl vinyl silicone rubber; then plasticize and granulate each raw material, The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap