Preparation method of paper sheets with gypsum whiskers

A technology of gypsum whiskers and paper sheets, applied in the field of papermaking, can solve the problems of low retention rate, waste, low retention rate, etc., and achieve the effects of low modification cost, low price, and reducing the load of anti-hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

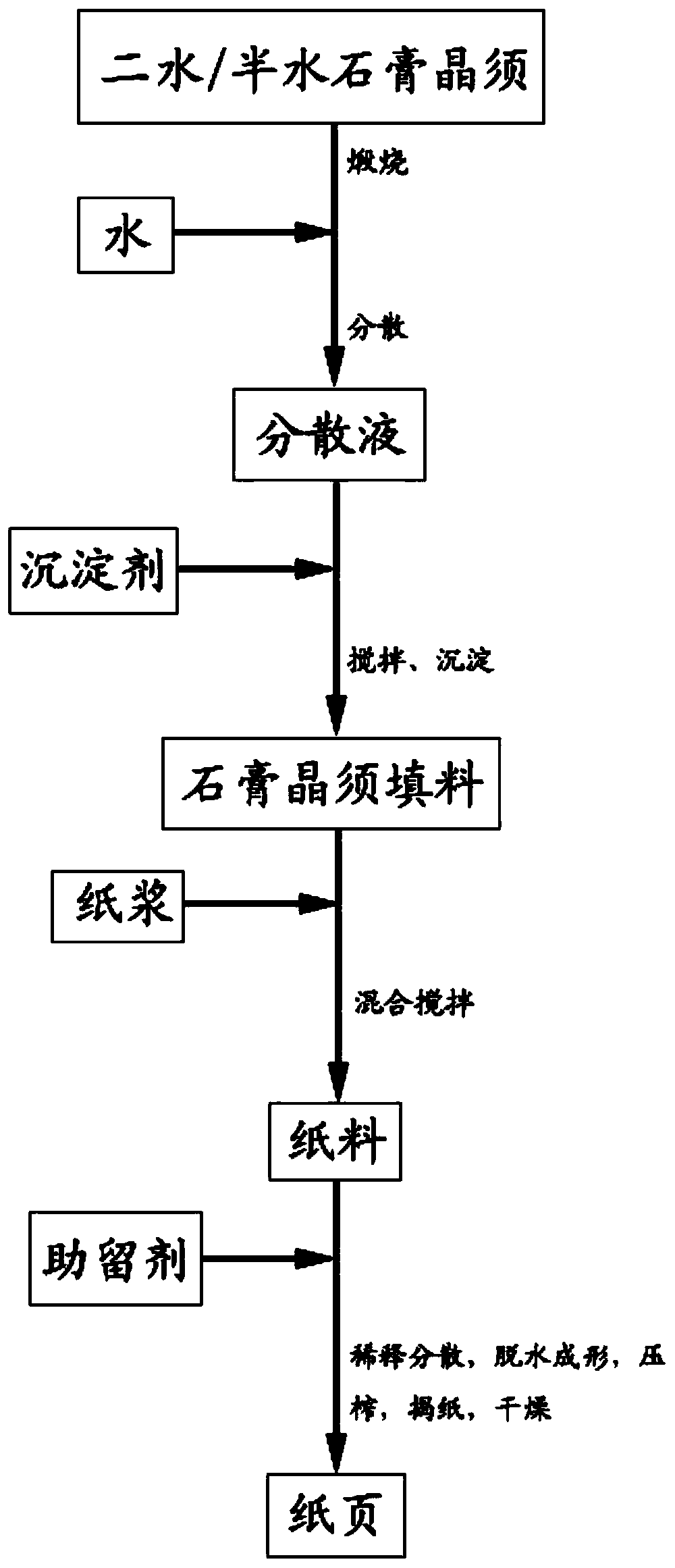

[0039] Such as figure 1 , the preparation method steps of the paper sheet filled with gypsum whiskers are as follows:

[0040](1) Take hemihydrate gypsum whiskers and / or dihydrate gypsum whiskers and put them in a muffle furnace, calcinate at 600°C for 30 minutes to obtain anhydrite whiskers, add water until the solid content is 1% to 2%, and disperse by ultrasonic vibration , to obtain a dispersion;

[0041] (2) Mix and stir after adding a precipitating agent to the dispersion liquid. The amount of the precipitating agent added is 3% of the anhydrite whisker quality. After precipitation, the gypsum whisker filler is obtained. The precipitating agent is composed of Ca(OH) 2 and NaAlO 2 Composition, the molar ratio is 2:1, that is, the weight ratio is 148:82, and it is obtained after being fully dispersed and mixed in a plastic cup;

[0042] (3) Add gypsum whisker filler to a beating concentration of 2%, and beat with a Valli beater until the beating degree is 37.0 0 SR blea

Embodiment 2

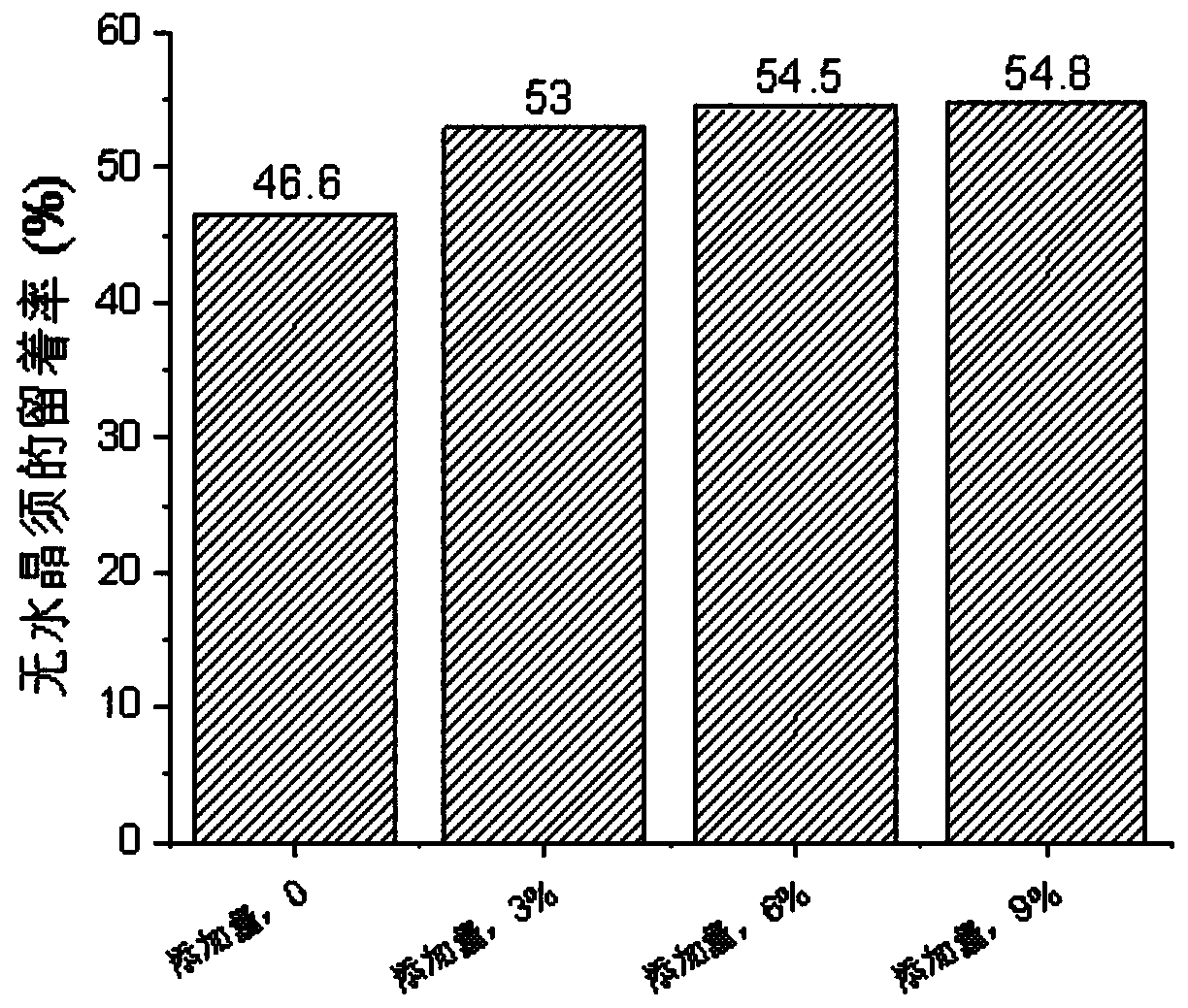

[0044] Effect of Precipitating Agent on the Retention Rate of Anhydrite Whiskers in Paper Sheets

[0045] (1) Preparation of anhydrite whiskers

[0046] The hemihydrate gypsum whiskers were put into a muffle furnace and calcined at 600°C for half an hour, and the obtained anhydrite whiskers were used for subsequent modification and paper filling.

[0047] (2) Preparation of retention aids

[0048] Cationic polyacrylamide (CPAM) with a molecular weight of about 6 million to 8 million is used as a retention aid. When making paper, the amount of CPAM added is 250ppm (to the absolute dry fiber content). Take 0.200g CPAM and dissolve it in 200ml water, stir slowly with an electromagnetic stirrer, and dissolve for more than 8h, then the concentration is 0.1%. Take 44g of the solution and use deionized Dilute it with water to 200g, and the amount of CPAM diluent for each sheet of paper is 2.5ml when making paper.

[0049] (3) Beating of pulp and dispersion of anhydrite whiskers

[0

Embodiment 3

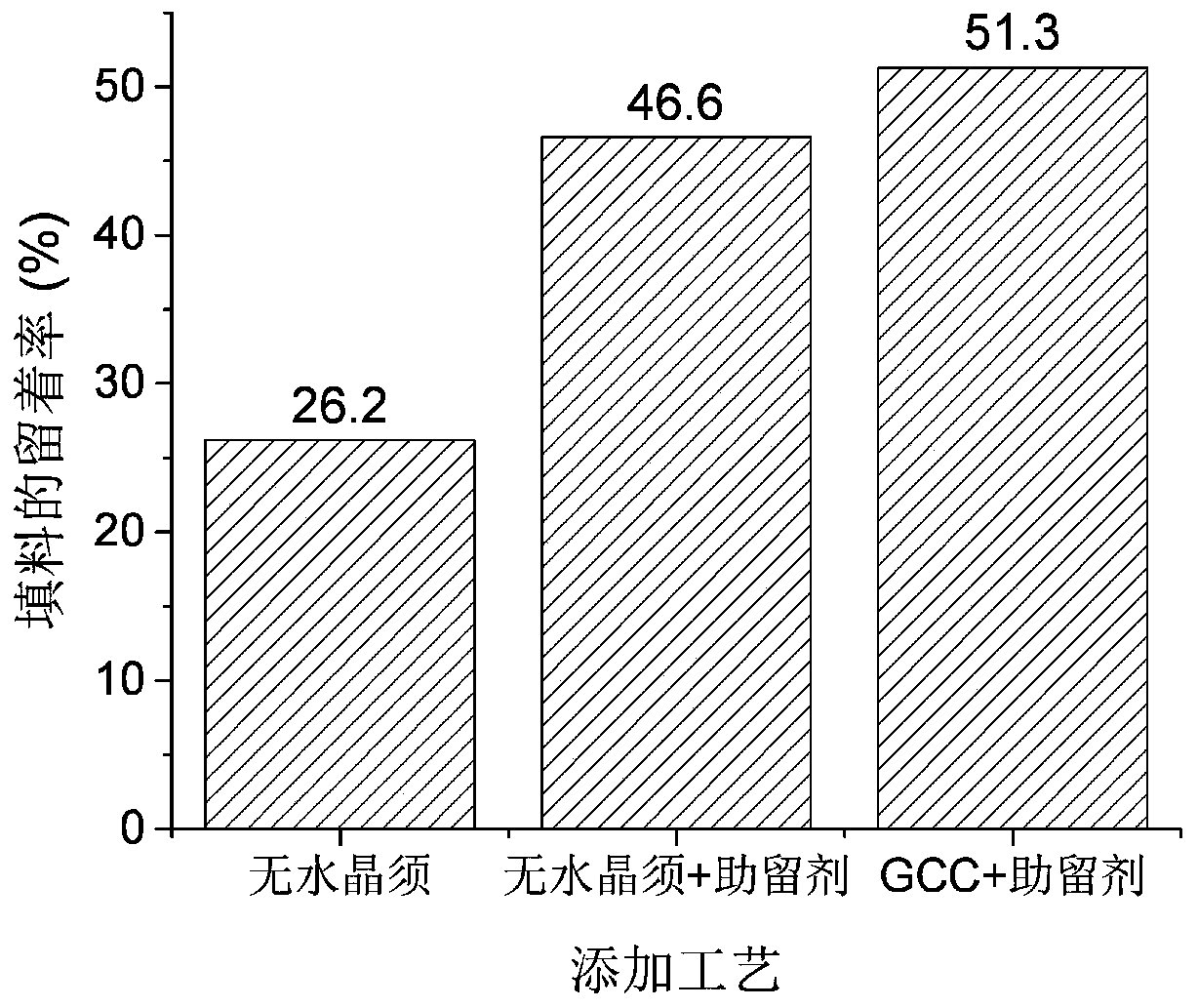

[0060] Compared with the effect of filler modified without precipitant

[0061] With the anhydrite whisker after method calcining in the embodiment of the present invention 1 and the commonly used filler of papermaking grind calcium carbonate (GCC) to add and fill paper page, filling amount is 15% equally, investigates retention aid CPAM simultaneously (to pulp fiber content 250ppm), the paper is filled with a comparative experiment, the results are as follows image 3 shown by image 3 It can be seen that when no retention aids are used, the retention rate of anhydrite whiskers is very low, which is 26.2%. When adding retention aids and filling normally, the retention rate of GCC is 51.3%, while the retention rate of anhydrite crystal whiskers is 51.3%. The retention rate of whiskers is not as good as that of GCC, which is only 46.6%, and the effect is not good. When the anhydrite whiskers are modified by adding a precipitating agent, the retention rate reaches about 54% in the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap